When comparing heating elements for industrial or commercial use, understanding the differences between a cartridge heater with thermocouple and an immersion heater is crucial. Both serve the purpose of heating, but they do so in distinct ways, making them suitable for different applications.

Understanding Cartridge Heaters

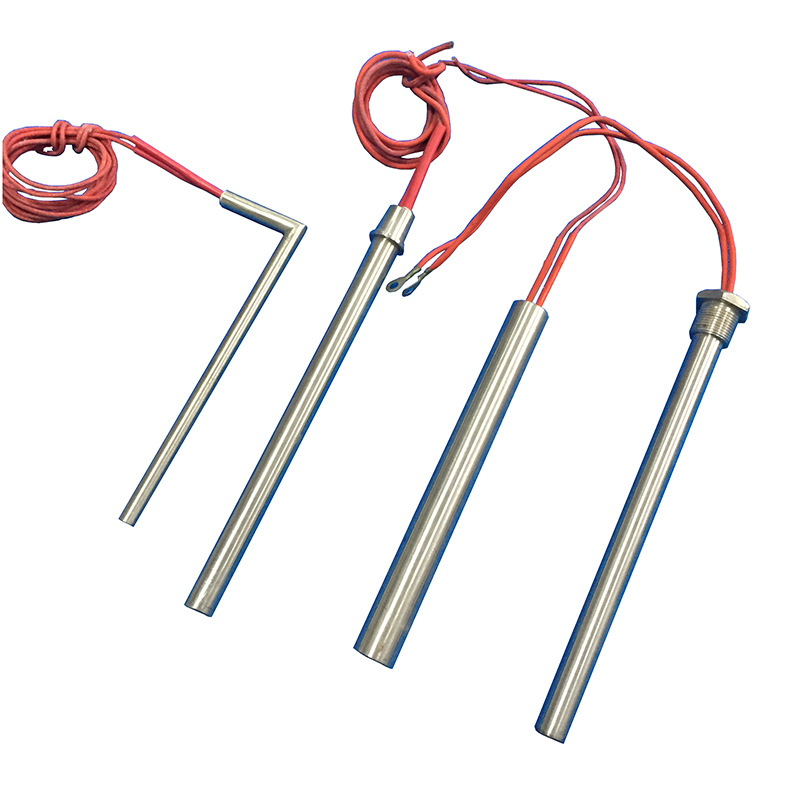

Cartridge heaters are compact, cylindrical heating elements designed to fit into holes or spaces within a material. They are primarily used to heat metal parts, molds, or dies where precise temperature control is needed.

- Construction: A cartridge heater consists of a resistance coil, typically made of nickel-chromium, that is insulated by magnesium oxide powder. This coil is housed within a sheath, often made of stainless steel or Incoloy, which protects it from high temperatures and corrosion.

- Thermocouple Integration: A key feature of the cartridge heater with thermocouple is its ability to monitor and control the temperature. The thermocouple is embedded within the heater, providing real-time temperature feedback, which helps in maintaining precise control over the heating process.

- Applications: Cartridge heaters are ideal for applications requiring focused, high-temperature heating. They are commonly used in the plastics industry, packaging machines, medical devices, and the automotive industry.

Understanding Immersion Heaters

Immersion heaters, on the other hand, are designed to be immersed directly into the fluid or material that needs to be heated. They are widely used in industries where large volumes of liquid or gas require efficient heating.

- Construction: Immersion heaters consist of tubular heating elements that are submerged in the medium to be heated. The heating elements are typically made of copper, steel, or Incoloy, depending on the application. The elements can be shaped in different configurations, such as U-shaped, straight, or circular, to fit the specific needs of the application.

- Thermocouple Integration: Like cartridge heaters, immersion heaters can also be equipped with a thermocouple for precise temperature control. The thermocouple monitors the temperature of the fluid, allowing for automatic adjustments to maintain the desired heat level.

- Applications: Immersion heaters are used in various industries, including chemical processing, oil and gas, food and beverage, and water heating systems. They are ideal for heating large volumes of liquid, such as water, oils, or chemicals.

Key Differences Between Cartridge Heaters and Immersion Heaters

While both cartridge heaters and immersion heaters are designed to provide heat, they differ in several key aspects:

- Heating Method:

- Cartridge Heater: Provides localized heat directly to solid materials or small spaces.

- Immersion Heater: Heats liquids or gases by direct immersion in the medium.

- Applications:

- Cartridge Heater: Best suited for precise heating of metal parts, molds, or confined spaces.

- Immersion Heater: Ideal for heating large volumes of fluids or gases, such as in industrial tanks or containers.

- Installation:

- Cartridge Heater: Typically installed in a drilled hole or small cavity within the material to be heated.

- Immersion Heater: Installed by submerging the heating element directly into the liquid or gas to be heated.

- Temperature Control:

- Cartridge Heater with Thermocouple: Provides highly accurate temperature control, making it suitable for applications requiring exact temperature regulation.

- Immersion Heater: While it can also be equipped with a thermocouple, it is generally used for applications where broader temperature control is acceptable.

Choosing the Right Heater for Your Needs

Selecting between a cartridge heater with thermocouple and an immersion heater depends on the specific requirements of your application.

- If precision is key, and you need to heat a small area or solid object, a cartridge heater is the better choice. The integration of a thermocouple ensures you can maintain tight control over the temperature, which is critical in processes like plastic molding or die casting.

- If you are heating large volumes of liquid or gas, an immersion heater is the way to go. It’s designed to efficiently heat larger spaces, making it perfect for industries that require bulk heating, like water treatment or chemical processing.

Last Word

Understanding the differences between a cartridge heater and an immersion heater helps in making an informed decision for your heating needs. Each has its strengths and is designed for specific applications, ensuring that you can achieve the desired temperature control and efficiency in your processes. Whether you need the pinpoint accuracy of a cartridge heater with thermocouple or the broad heating capacity of an immersion heater, knowing these distinctions will guide you to the best choice for your industrial needs.