A thermocouple is one of the most reliable tools for measuring temperature in industrial and scientific applications. Known for its durability and precision, it is an essential component across industries like aerospace, automotive, and manufacturing. Whether you’re monitoring extreme heat in a furnace or tracking cooling rates in food processing, thermocouples provide accurate data critical for success.

Let’s explore the five key benefits of a thermocouple that makes it indispensable.

1. Wide Temperature Range

One of the biggest advantages of a thermocouple is its ability to measure temperatures across a vast range. From cryogenic levels as low as -250°C to extreme heat exceeding 2,300°C, thermocouples outperform most alternatives:

- Type K Thermocouple: The most commonly used, ideal for temperatures ranging from -200°C to 1,260°C.

- Type S Thermocouple: Accurate at temperatures above 1,500°C, making it suitable for metallurgy and glass production.

This versatility allows industries to rely on thermocouples for diverse processes without switching between instruments.

2. Fast Response Time

Thermocouple is designed for real-time temperature readings. They respond instantly to temperature changes due to their compact size and direct contact with the environment being measured.

- In applications like chemical reactors and gas turbines, rapid readings ensure safety and process efficiency.

- The absence of lag makes thermocouples ideal for dynamic systems where constant monitoring is essential.

This speed gives industries the ability to make quick decisions, minimizing risks and optimizing outcomes.

3. Durability in Harsh Environments

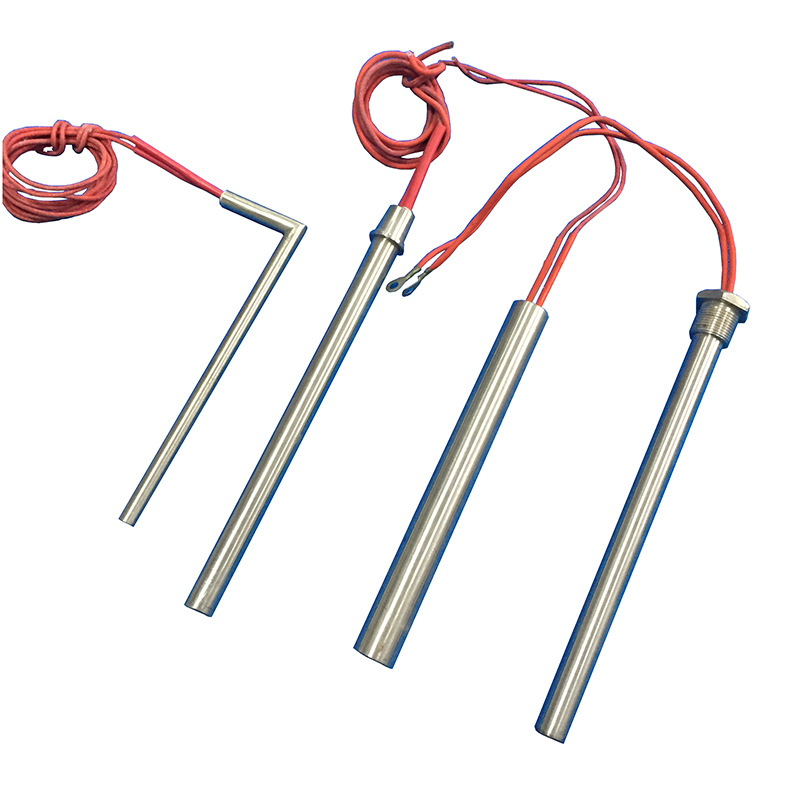

Industries often require equipment that can withstand harsh and extreme conditions. Thermocouple is built to perform reliably under such circumstances:

- Corrosion Resistance: Made with robust materials like stainless steel and Inconel, thermocouples resist damage in chemically aggressive environments.

- Shock and Vibration Tolerance: Used in engines and turbines, thermocouple continues to deliver accurate readings under constant mechanical stress.

Their rugged design makes them an excellent choice for heavy-duty industries like oil and gas and aerospace.

4. Cost-Effective Solution

Thermocouple offers an excellent balance between performance and affordability. Their simple construction and wide availability keep manufacturing costs low.

- Low Maintenance Requirements: Unlike other temperature sensors, thermocouples are durable and often require minimal upkeep.

- Longevity: A properly installed thermocouple can last for years, reducing the need for frequent replacements.

This makes them a practical option for businesses looking to manage costs while maintaining operational efficiency.

5. Compatibility with Advanced Systems

Thermocouples integrate seamlessly with modern monitoring systems. They are compatible with:

- Digital Displays: For easy temperature tracking.

- Data Loggers: Useful for recording temperatures over time.

- Automated Controls: Essential for precision manufacturing and process optimization.

This adaptability ensures thermocouple remains relevant as industries advance technologically.

Real-World Applications of a Thermocouple

- Furnace Monitoring: Ensures temperature consistency in metal and ceramic production.

- HVAC Systems: Maintains optimal heating and cooling performance.

- Food Processing: Tracks cooking and freezing conditions for quality control.

Their reliability and versatility make thermocouples a preferred choice across these sectors.

Final Words

A thermocouple is more than just a temperature sensor; it’s a key to precision, efficiency, and safety in industrial and scientific processes. Its unmatched temperature range, quick responsiveness, and adaptability make it a must-have tool. For industries looking to improve operations while keeping costs under control, thermocouples are the perfect solution.