Mineral Insulated (MI) heating cable is a reliable solution for industries that require efficient and safe heat management. MI heating cable manufacturers design these cables to work in demanding conditions, offering unmatched durability and performance. These cables are made with a copper or stainless steel sheath and magnesium oxide insulation, making them heat-resistant and highly durable. This blog explains how MI heating cables are used in various applications, why they are effective, and their benefits in different industries.

What is Mineral Insulated MI Heating Cable?

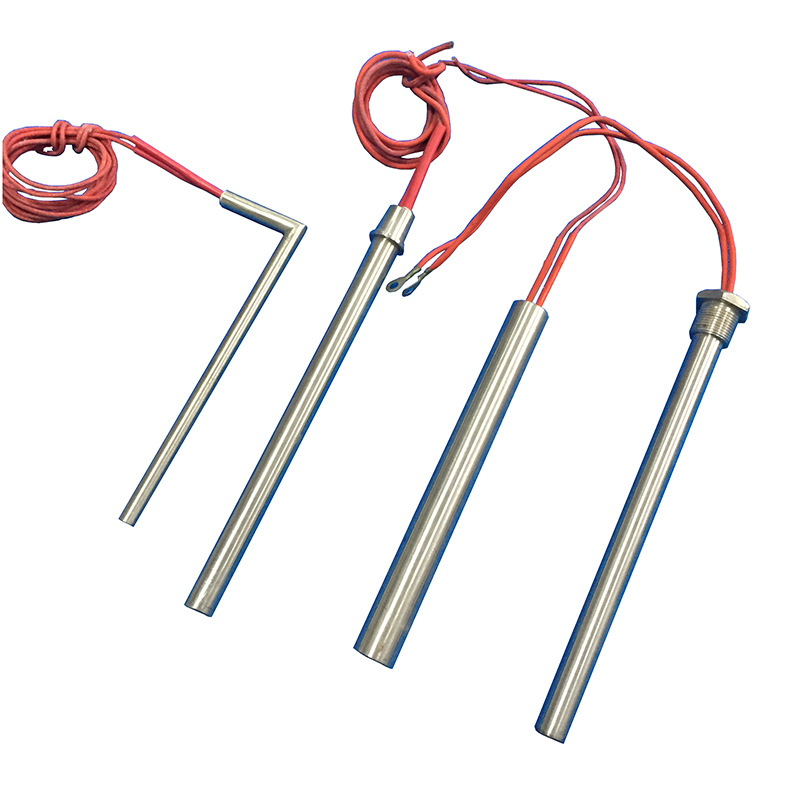

MI heating cables are electrical cables designed to generate heat. They are composed of:

- Metal Sheath: Protects the cable from external damage.

- Magnesium Oxide Insulation: Acts as a fireproof insulator, ensuring safety and high performance.

- Heating Element: Produces heat when powered by electricity.

These features make MI heating cables resistant to high temperatures, chemicals, and moisture.

Applications of MI Heating Cable

MI heating cables are versatile and serve various industries. Here are the main areas where they are used:

- Process Heating

MI cables are used to maintain or increase temperatures in pipelines, tanks, and vessels. Key industries include:

- Chemical: To prevent the crystallization of chemicals during transport.

- Oil and Gas: For heating pipelines to avoid blockages due to wax formation.

- Food and Beverage: Ensures consistent temperatures in processing systems.

- Frost Protection

These cables are installed to prevent freezing in pipes and equipment. Common areas include:

- Residential water supply systems.

- Fire safety sprinkler systems.

- Outdoor pipes exposed to low temperatures.

- Snow Melting Systems

MI heating cables are embedded in driveways, walkways, and ramps to melt snow and ice, ensuring safety during winter. - Industrial Equipment Heating

In industries, MI cables maintain optimal operating temperatures for:

- Boilers.

- Heat exchangers.

- Reactors and distillation columns.

Why Choose MI Heating Cables?

MI heating cables are preferred for their unique properties:

- Durability: Their robust design withstands harsh environmental conditions.

- Fireproof: Magnesium oxide insulation prevents fire risks.

- Moisture Resistance: Ideal for damp and wet environments.

- Flexible Design: Easy to shape and install on curved surfaces.

Benefits of MI Heating Cables

Here are some benefits of using MI heating cables:

- High-Temperature Resistance

MI heating cables can operate at temperatures as high as 1000°C without degradation. - Long Lifespan

Their corrosion-resistant sheath and insulation offer years of reliable operation, reducing replacement costs. - Energy Efficiency

These cables efficiently transfer heat, reducing energy loss and operating costs.

How to Install MI Heating Cable

Installing MI heating cables requires careful planning and professional expertise. Follow these steps:

- Design the System: Define the heating requirements and calculate the cable length.

- Choose the Right Cable: Select a cable that matches the system’s voltage and temperature range.

- Prepare the Surface: Clean the surface to ensure proper heat transfer.

- Install the Cable: Secure the cable using appropriate clamps or fasteners.

- Connect the Power Supply: Use junction boxes to connect the cable safely.

- Test the System: Check for consistent heating before regular use.

Wrap Up

MI heating cables are essential for industries needing safe and reliable heat management. Their durability, high-temperature resistance, and versatility make them a preferred choice. MI heating cable manufacturers have revolutionized heating solutions with their innovative designs. Whether for industrial processes, frost protection, or snow melting systems, MI heating cables ensure efficiency and safety in challenging environments.