When it comes to managing wires and cables efficiently, high temperature cable sleeves manufacturers play a crucial role. Cable sleeves are essential for organizing, protecting, and ensuring the safety of cables in various environments. They come in different types, each serving specific purposes, and choosing the right one can make a big difference in performance and durability.

In this post, we will explore the different types of cable sleeves, their features, and their applications.

What Are Cable Sleeves?

Cable sleeves are coverings designed to bundle and protect cables from external damage. They shield wires from heat, abrasion, chemicals, and moisture. This helps improve safety and enhances the lifespan of cables.

Why Are Cable Sleeves Important?

Cable sleeves are not just for appearance. They prevent accidents, reduce wear and tear, and improve efficiency. Here’s why they are critical:

- Protection from heat and chemicals: Prevents melting or damage from extreme conditions.

- Organization: Keeps cables neat and accessible for maintenance.

- Improved safety: Reduces risks of electrical fires and hazards.

- Durability: Extends the life of cables by reducing environmental stress.

Types of Cable Sleeves

Here’s an in-depth look at the most common types of cable sleeves:

1. Braided Cable Sleeves

Braided sleeves are flexible and durable. They are woven with strong fibers that expand or contract to fit over cables.

- Key Features:

- Resistant to abrasion and chemicals.

- Allows airflow, preventing overheating.

- Can be used in industrial, automotive, and home settings.

- Common Materials: Nylon, polyester, or stainless steel.

- Applications: Ideal for bundling wires in computers, appliances, and heavy machinery.

2. Heat-Shrink Sleeves

Heat-shrink sleeves are tubes that shrink when heated, forming a tight fit around cables.

- Key Features:

- Provides a secure and waterproof seal.

- Protects against moisture and corrosion.

- Available in different sizes and colors for easy identification.

- Common Materials: Polyolefin and fluoropolymer.

- Applications: Widely used in electronics, automotive wiring, and electrical repairs.

3. Spiral Wrap Sleeves

These are coiled sleeves that wrap around cables, providing flexibility and access to individual wires.

- Key Features:

- Easy to install and remove.

- Allows branching out of cables at any point.

- Lightweight and reusable.

- Common Materials: Polyethylene or nylon.

- Applications: Suitable for home offices, telecommunications, and automation systems.

4. Split Loom Sleeves

Split loom sleeves have a split design for easy installation over existing cables.

- Key Features:

- Protects against abrasion and UV rays.

- Flexible and lightweight.

- Allows quick access for maintenance.

- Common Materials: Polyethylene and polypropylene.

- Applications: Commonly used in automotive wiring and industrial equipment.

5. Fiberglass Sleeves

Fiberglass sleeves are designed to withstand extreme heat and are often coated for additional protection.

- Key Features:

- Can handle temperatures up to 1,200°F.

- Resistant to chemicals and moisture.

- Durable in harsh environments.

- Common Materials: Fiberglass with silicone coating.

- Applications: Used in high-temperature industries like aerospace, metallurgy, and power plants.

6. Velcro Cable Sleeves

Velcro sleeves are simple and reusable, offering a practical way to manage cables without permanent installation.

- Key Features:

- Adjustable and easy to reuse.

- Provides quick cable management.

- No tools required for installation.

- Common Materials: Nylon with Velcro strips.

- Applications: Perfect for home and office setups where cables need regular adjustment.

How to Choose the Right Cable Sleeve

Selecting the right cable sleeve depends on the application, environment, and type of cables. Consider the following:

- Temperature Resistance: For high-heat areas, choose fiberglass or heat-shrink sleeves.

- Flexibility: Use braided or spiral wraps for maximum flexibility.

- Durability: For outdoor or industrial use, opt for UV-resistant and chemical-proof sleeves.

- Ease of Installation: Velcro or split loom sleeves are best for quick adjustments.

- Budget: Match your choice with your budget while ensuring long-term value.

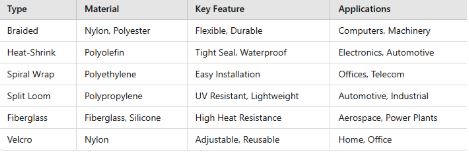

Comparison Table for Cable Sleeves

Wrap Up

Temperature cable sleeves manufacturers provide a variety of solutions to protect and organize cables. From heat-shrink tubes to flexible braided sleeves, there’s a type for every need. Proper cable management ensures safety, extends the lifespan of your equipment, and keeps your workspace tidy. When selecting a cable sleeve, always prioritize the specific requirements of your project to achieve the best results.