Tubular heaters are versatile heating devices used across various industries and applications. A trusted tubular heater manufacturer designs these heaters to provide efficient and controlled heat transfer. They are reliable, energy-efficient, and adaptable for different settings, making them a popular choice for many industries. Let’s explore what tubular heaters are and how they are used in everyday applications.

Understanding Tubular Heaters

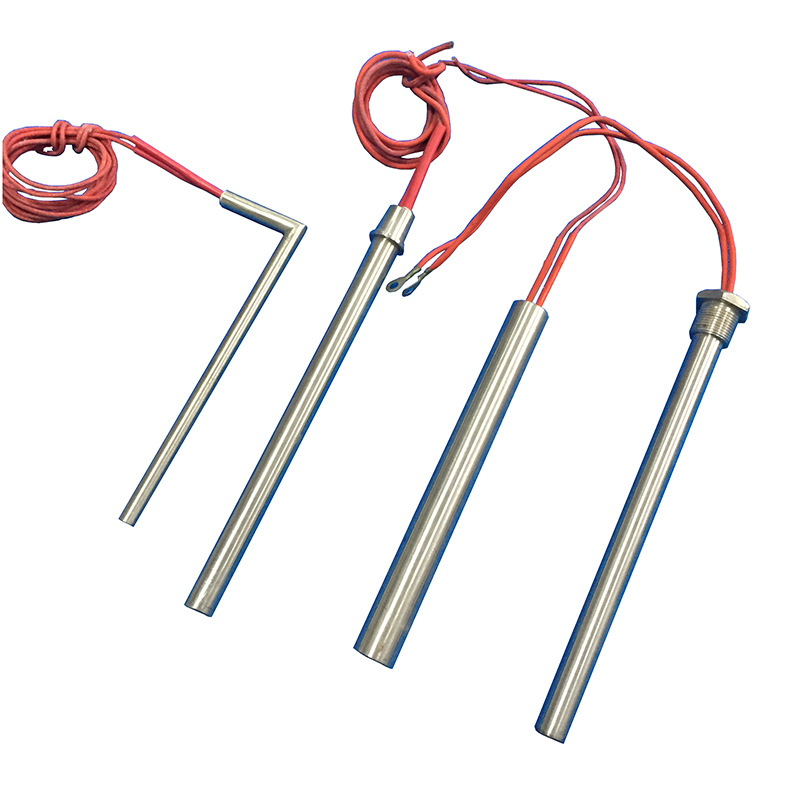

Tubular heaters are electrical heating elements made from metal tubes. Inside the tube, a high-resistance wire generates heat when powered by electricity. The design ensures durability, even in harsh environments. These heaters are available in different sizes, shapes, and configurations to meet specific needs. They can be straight, coiled, or formed into custom shapes.

Key Features of Tubular Heaters

- Durable Design: Made with high-quality materials for long-lasting performance.

- Versatility: Suitable for heating liquids, gases, and solid surfaces.

- Energy Efficiency: Provides effective heating with minimal energy waste.

- Customizable: Can be tailored for specific temperature ranges and applications.

- Corrosion Resistance: Withstands challenging environments like moisture or chemicals.

Applications of Tubular Heaters

Tubular heaters are widely used due to their adaptability. Below are some common applications:

1. Industrial Heating

Industries use tubular heaters for heating processes in factories and workshops. These heaters help with drying, melting, and curing materials.

- Heating tanks for liquids.

- Preheating molds and dies.

- Industrial ovens for baking and drying.

2. HVAC Systems

Tubular heaters play a vital role in heating and ventilation systems. They are used in:

- Duct heating to maintain warm airflow.

- Air curtains to reduce heat loss.

- Space heaters for localized temperature control.

3. Food Processing

In food manufacturing, tubular heaters are essential for maintaining consistent temperatures during processing. Examples include:

- Baking equipment.

- Fryers for heating oil.

- Warming plates and food storage units.

4. Water and Liquid Heating

Tubular heaters are ideal for heating water and other liquids. They are commonly used in:

- Boilers and water heaters.

- Chemical processing tanks.

- Oil heaters for industrial use.

5. Medical Equipment

The medical field uses tubular heaters for sterilization and other heating requirements. Some examples are:

- Sterilizers to kill bacteria.

- Incubators to maintain controlled environments.

6. Appliances

Home appliances also depend on tubular heaters for efficiency. Common examples include:

- Dishwashers to heat water.

- Ovens for cooking.

- Electric kettles and coffee machines.

Choosing the Right Tubular Heater

To choose the best tubular heater for your needs, consider the following:

- Material: Choose corrosion-resistant materials like stainless steel for durability.

- Watt Density: Match the power output to the application for efficient heating.

- Size and Shape: Ensure the heater fits your equipment perfectly.

- Temperature Control: Opt for heaters with adjustable settings for better control.

Maintenance Tips for Tubular Heaters

- Regular Cleaning: Remove dust and debris to maintain efficiency.

- Check for Damage: Inspect for wear or corrosion regularly.

- Avoid Overloading: Use within the recommended voltage and wattage limits.

- Replace When Necessary: If performance decreases, replace the heater promptly.

Final Words

Tubular heaters are essential in various industries, from food processing to medical equipment. They offer reliable and efficient heating solutions for liquids, gases, and solid surfaces. Whether used in industrial settings or home appliances, their durability and adaptability make them a smart choice. By selecting a heater from a trusted tubular heater manufacturer, you ensure high performance and long-lasting reliability.