Precision heating is non-negotiable when handling temperature-sensitive liquids. A band heater manufacturer plays a critical role in this by supplying solutions tailored for industrial tanks.

Band heaters apply consistent heat across the tank’s surface, ensuring product integrity without thermal gradients. But using one correctly requires more than just wrapping it around a vessel.

Here’s how to use a band heater for tanks effectively, based on technical guidelines and real-world application data.

Understand the Purpose of Band Heaters

Band heaters are designed to:

- Maintain fluid viscosity in resins, oils, or chemicals

- Prevent freezing in cold environments

- Raise process temperature for reactivity or flow control

Before choosing a heater, determine the tank material, volume, fluid type, and ambient temperature. Different materials like stainless steel or poly tanks conduct heat differently, which directly affects heater efficiency.

Choose the Right Band Heater Type

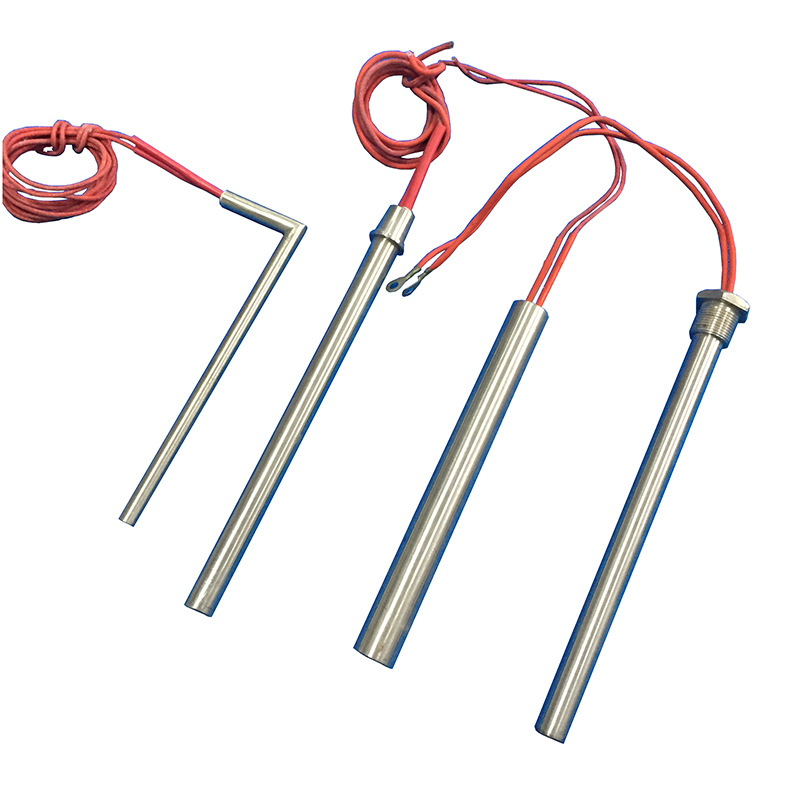

A reputable band heater manufacturer offers several models. Each type fits specific use cases:

- Mica insulated heaters – Ideal for low- to medium-temperature applications (up to 900°F). Cost-effective and commonly used.

- Ceramic band heaters – Better for high temperatures (up to 1200°F) and energy efficiency. They reduce heat loss via insulation.

- Mineral-insulated heaters – Provide the highest watt densities and fastest heat-up times.

Measure Correctly

Improper sizing is a common mistake. Measure the outside diameter of the tank accurately. Also, measure the height of the area to be heated. Band heaters come in custom sizes and are often manufactured per order.

Install the Band Heater Securely

Follow these steps:

- Wrap the heater tightly around the tank.

- Tighten the clamping mechanism (usually a strap or barrel nut) evenly to avoid air gaps.

- For ceramic types, preheat slightly before tightening if required. This prevents cracking.

- Check all electrical connections before energizing the heater.

Apply Proper Thermal Insulation

Most heat loss occurs through radiation and convection. Adding insulation over the heater:

- Increases efficiency

- Reduces power consumption

- Protects personnel from burns

Use high-temperature blankets or fiberglass wraps approved for the heater’s rated temperature.

Control the Temperature Accurately

Don’t rely on guesswork. Install a thermocouple or RTD sensor near the heating zone. Connect it to a PID temperature controller to automate and regulate heat delivery. Smart controllers can also log data and detect system faults.

Safety Precautions Matter

Working with electrical heaters requires discipline:

- Use ground-fault circuit interrupters (GFCI)

- Ensure proper grounding of the heater

- Install over-temperature protection systems

- Regularly inspect for wear or exposed wiring

Maintenance Checklist

A well-maintained heater performs longer and more efficiently:

- Inspect clamping tightness every 30–60 days

- Check electrical terminals for corrosion or looseness

- Clean debris from the heater and the surrounding insulation

- Replace worn components from the same band heater manufacturer for compatibility

Common Mistakes to Avoid

- Using the wrong watt density for plastic tanks (risk of melting)

- Leaving air gaps under the band

- Skipping thermal control

- Running heaters dry (no product in the tank)

Why Work With a Trusted Band Heater Manufacturer

Every top band heater manufacturer, like Cheri Heater, offers:

- Engineering consultation

- Custom-fit designs

- Certified safety standards

- Long-term technical support

This ensures that your heater matches your exact tank specs and process needs.

Final Thoughts

Using a band heater for tanks is not just about applying heat. It’s about precision, safety, and efficiency. Start by choosing the right heater type, size it properly, and pair it with a smart control system. Regular maintenance and working with a trusted band heater manufacturer are what separate reliable performance from premature failure.