Precision printing depends on consistent temperatures. Without a reliable heat source, even the most advanced 3D printers fail to produce quality results. That’s where a cartridge heater for 3D printer comes in, a core component behind accurate, high-quality filament extrusion. Most users don’t realize how critical this small device is to maintaining performance and preventing failures.

Whether you’re using PLA or high-temperature materials like ABS or Nylon, the heater ensures optimal flow through the hotend.

Here’s everything you need to know to choose the right one, avoid underperformance, and extend your printer’s life.

What is a Cartridge Heater for 3D Printer?

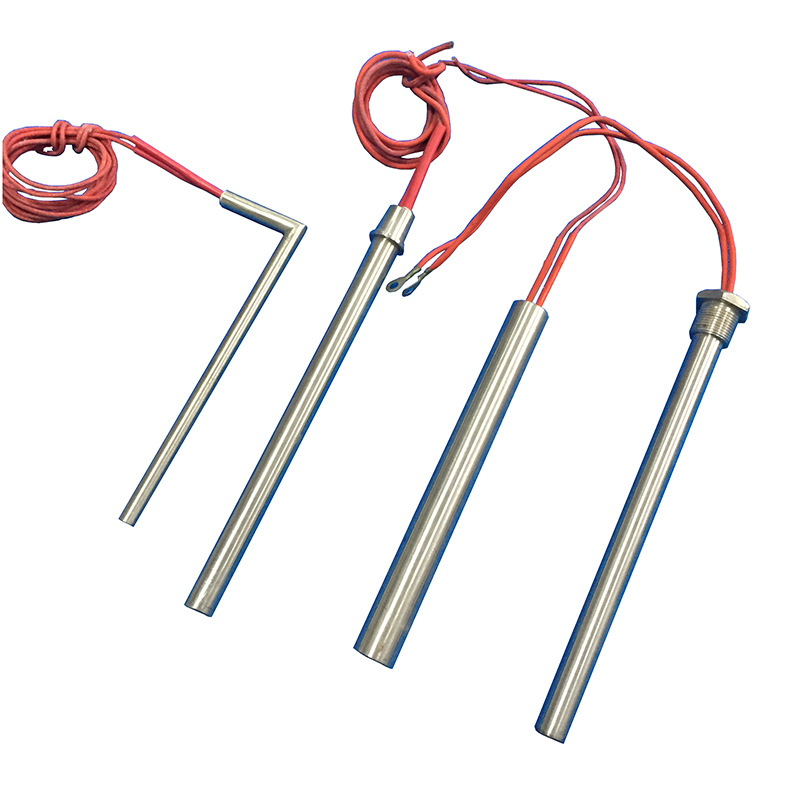

A cartridge heater for 3D printer is a compact heating element embedded in the hotend. It heats the nozzle to the precise temperature needed to melt thermoplastic filament. Unlike open coil heaters, cartridge heaters offer better insulation, faster heating times, and focused thermal transfer.

These heaters are cylindrical, stainless steel-clad components filled with magnesium oxide insulation and resistance wire. They are designed to withstand continuous high temperatures and fit snugly into the hotend block. Their tight fit ensures maximum heat transfer.

Why It Matters in 3D Printing

Temperature fluctuation causes weak prints, clogged nozzles, and inconsistent layer adhesion. A properly functioning cartridge heater for 3D printer prevents:

- Under-extrusion, which results from a heater not reaching or maintaining set temperature.

- Thermal runaway which can damage your printer or even pose safety risks.

- Material incompatibility, especially with high-temp filaments like PC or Nylon.

Without stable heat control, even calibrated printers will struggle with warping and layer delamination.

Key Features to Look For

Not all cartridge heaters are equal. Selecting the right one means better performance and longer lifespan.

Here are essential factors to consider:

- Wattage: Standard printers work well with 30W or 40W heaters. However, for high-temp filaments, a 50W heater may be required. Higher wattage provides faster heat-up times and better temperature stability.

- Voltage: Match the heater’s voltage rating to your printer’s power supply—typically 12V or 24V. A mismatch can cause power issues or failure to reach temperature.

- Diameter and Length: Most hotends require a 6mm diameter heater, with lengths varying between 20mm and 30mm. Confirm compatibility with your hotend block before purchasing.

- Leads: Look for high-temperature silicone or fiberglass-insulated wires. Poor insulation leads to short circuits or wire degradation.

- Sensor compatibility: Some heaters come bundled with thermistors or are designed to work closely with specific temperature sensors. This ensures accurate heat regulation.

When to Replace Your Cartridge Heater

Over time, heaters degrade. Resistance wires oxidize, insulation wears, and heating becomes unreliable. Common signs you need a replacement include:

- Slow heat-up times

- Failure to reach or hold the target temperature

- Repeated thermal errors during prints

- Visible wear on wires or casing

If your print quality suddenly drops or your printer frequently throws errors, don’t overlook the heater. Replacing it early prevents damage to the hotend or mainboard.

Best Practices for Installation

Improper installation can reduce efficiency or cause heater failure. Follow these guidelines:

- Clean the hotend block before inserting the heater. Any debris can reduce thermal contact.

- Apply thermal paste (if recommended) for improved heat transfer.

- Secure the heater firmly with a grub screw or clamp, ensuring it doesn’t slide during operation.

- Avoid bending heater wires sharply near the metal casing. This weakens the internal connection.

- Perform a PID tune after installing a new heater to optimize temperature control.

Which Materials Require Stronger Heaters?

Different filaments need different temperatures:

- PLA: 180°C to 210°C – standard heaters suffice.

- ABS: 230°C to 250°C – benefit from stable heat, especially with enclosed printers.

- PETG: 230°C to 250°C – requires consistent heating for smooth extrusion.

- Nylon, Polycarbonate, PEI: 260°C to 300°C – demand a high-watt cartridge heater for 3D printer with robust insulation.

Printing exotic materials? Invest in an all-metal hotend and a 50W or 60W cartridge heater to handle extreme temps without failure.

Final Thoughts

The cartridge heater for 3D printer may seem small, but its impact is massive. A high-quality heater ensures consistent extrusion, reliable temperature control, and better print finishes. It also protects your investment by preventing hotend damage and thermal errors. Whether you’re replacing a worn-out unit or upgrading for high-performance printing, choosing the right heater is essential for dependable results. Always verify compatibility and never compromise on build quality.