Cartridge heaters play one of the most crucial roles in modern industrial heating solutions. Whether you’re in plastic moulding, packaging, food processing, or heavy machinery, these compact heating elements offer reliability, precision, and high performance.

What Are Cartridge Heaters?

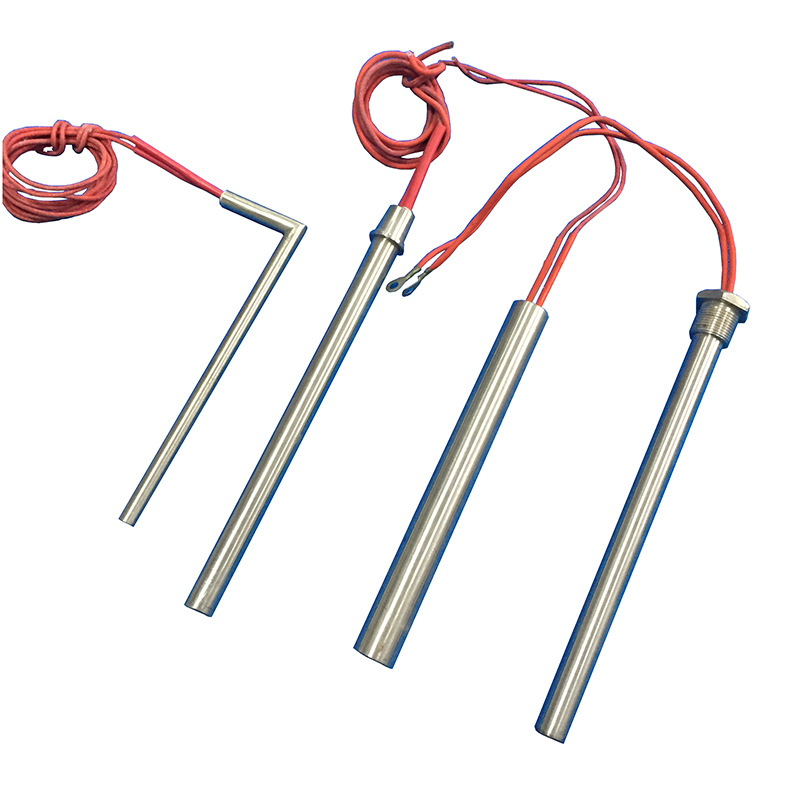

A cartridge heater is a cylindrical, tube-shaped heating element designed to deliver concentrated heat in small, confined areas. Think of them as the “power heaters” installed inside metal blocks, dies, and moulds to maintain consistent temperature.

Why Cartridge Heaters Are Essential in Modern Industries

Today’s industries rely heavily on precision heating. Cartridge heaters offer:

-

Fast heating performance

-

High watt density

-

Perfect temperature accuracy

This makes them ideal for production lines where speed and consistency matter.

Types of Cartridge Heaters

High-Watt Density Cartridge Heaters

These heaters are engineered for high-temperature applications. They deliver strong, fast heat and are commonly used in industrial machines requiring intense heating.

Low-Watt Density Cartridge Heaters

Perfect for sensitive heating applications where too much heat can damage components. They offer stable and controlled heating.

Swaged vs. Non-Swaged Cartridge Heaters

-

Swaged: Dense insulation, faster heating, and longer life.

-

Non-swaged: More economical and suitable for basic applications.

Key Features of High-Quality Cartridge Heaters

Temperature Control & Heating Speed

Premium heaters reach the desired temperature quickly while maintaining stability.

Material Quality

High-grade stainless steel and nickel-chromium wires ensure durability and performance.

Customization Options

Top suppliers offer custom lengths, diameters, watt densities, and lead configurations based on industrial needs.

Applications of Cartridge Heaters

Packaging Industry

Used in sealing machines and cutting systems for accurate and fast heating.

Plastic Moulding

Heaters ensure moulds stay at the right temperature for smooth production.

Food Processing

Helps maintain stable temperatures in cooking, drying, and processing machinery.

Medical & Laboratory Equipment

Used in sterilizers, analytic devices, and precision instruments.

How to Choose the Best Cartridge Heater Manufacturers

Manufacturing Standards

Always choose a manufacturer that follows ISO and CE-certified production standards.

Certifications & Quality Checks

Ensure they conduct insulation resistance tests, watt density analysis, and temperature tests.

Customer Support & After-Sales Service

A reliable supplier provides guidance, warranty, and technical help when needed.

Best Cartridge Heater Manufacturers and Suppliers

China-Based Manufacturers

China leads the global cartridge heater market due to:

-

Advanced manufacturing

-

High-quality materials

-

Competitive pricing

Top Chinese manufacturers supply millions of heaters worldwide.

USA-Based Manufacturers

Known for premium quality and high-end custom heaters.

European Manufacturers

Offer durable heaters with strict quality control.

Why China Leads Global Cartridge Heater Supply

China’s technology, skilled labour, and bulk production capacity make it ideal for buyers seeking both quality and affordability.

Benefits of Buying from Reliable Suppliers

Longer Heater Life

Good manufacturers use quality insulation and heating wires.

Increased Efficiency

Reliable heaters heat faster and save electricity.

Cost Savings

Low maintenance and longer lifespan reduce replacement costs.

How to Evaluate a Supplier Before Buying

Product Testing

Check temperature accuracy and durability.

Sample Orders

Always test samples before bulk orders.

Check Online Reviews

Buyer feedback reveals the supplier’s reliability.

Pricing Guide for Cartridge Heaters

Factors That Affect the Cost

-

Size

-

Watt density

-

Customization

-

Lead type

Price Comparison: China vs Global Markets

Chinese suppliers offer the most competitive rates while maintaining high quality.

Tips for Maintaining Cartridge Heaters

Installation Tips

Ensure correct fit and avoid air gaps to prevent overheating.

Safety Tips

Use temperature controllers for safe operation.

Cleaning & Maintenance Guidelines

Regular checks increase heater lifespan.

Future Trends in Cartridge Heater Manufacturing

Smart Heating Technologies

IoT-based heaters with auto temperature control.

Eco-Friendly Heater Designs

Manufacturing using recyclable materials and energy-efficient methods.

Conclusion

Cartridge heaters are essential for modern industrial operations, offering precision, durability, and performance. Choosing the right manufacturer ensures efficient production, cost savings, and long-term reliability. Whether buying from China, the USA, or Europe, always focus on quality, certifications, and customization options.

FAQs

1. What is a cartridge heater used for?

It is used for precision heating in machinery, moulds, packaging systems, and laboratory equipment.

2. Which country makes the best cartridge heaters?

China, the USA, and Germany are globally leading suppliers.

3. How long does a cartridge heater last?

With proper maintenance, it can last several months to years depending on usage.

4. Are cartridge heaters customizable?

Yes, top manufacturers offer custom sizes, watt densities, and wiring options.

5. How do I maintain my cartridge heater?

Install correctly, avoid moisture, and check temperature settings regularly.