If you’ve ever worked in plastics, packaging, or industrial machinery, chances are you’ve already met the silent hero of heat control the band heater. But behind every high-performance band heater is a skilled band heater manufacturer working behind the scenes like a master craftsman shaping metal and heat into pure precision.

In this complete guide, we’re diving deep into the world of band heater manufacturing how it works, why it matters, how to choose the right manufacturer, and what the future holds. Let’s turn up the heat.

What Is a Band Heater?

A band heater is a cylindrical heating device designed to wrap around pipes, barrels, nozzles, and cylindrical surfaces. Its job is simple but powerful deliver consistent, controlled heat directly where it’s needed.

Think of it as a heated jacket that keeps industrial machines running at the perfect temperature.

Why Band Heaters Are Critical in Industrial Heating

Without proper heating, machines fail. Plastic won’t melt evenly. Extrusion lines slow down. Production quality drops. Band heaters ensure:

- Accurate temperature control

- Faster heat transfer

- Reduced energy wastage

- Stable production output

They are the backbone of temperature-sensitive manufacturing.

Manufacturing vs. Assembling

A true band heater manufacturer doesn’t just assemble parts they engineer solutions. They:

- Design heaters from scratch

- Select insulation materials

- Wind resistance elements

- Test electrical and thermal performance

This distinction separates premium manufacturers from basic suppliers.

Custom vs. Standard Production

While standard heaters are quick solutions, custom band heaters are precision tools built for unique machines, special voltages, and exact temperature ranges.

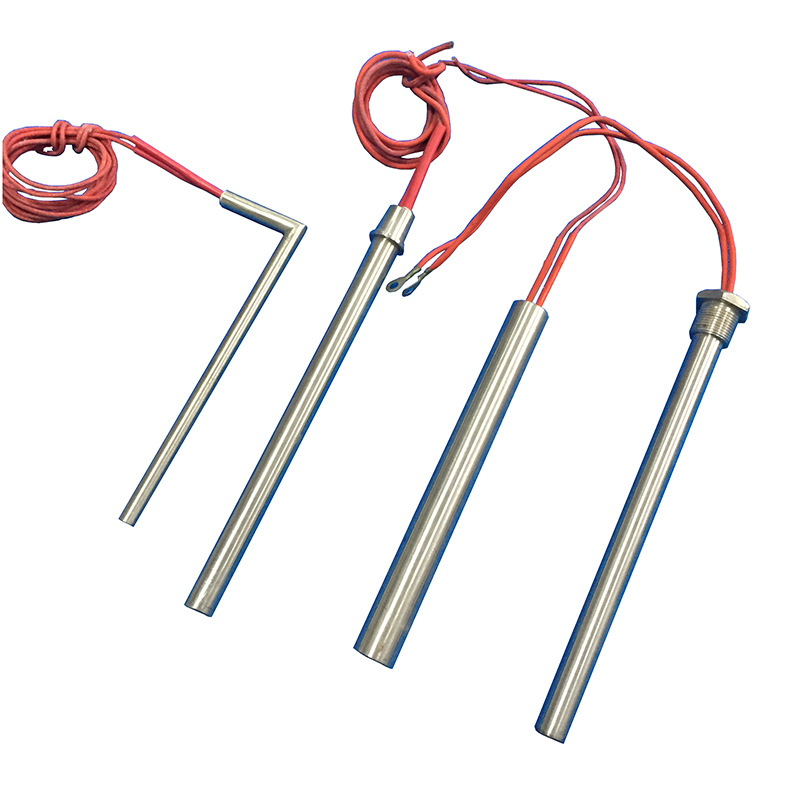

Types of Band Heaters

Mica Band Heaters

Lightweight, affordable, and widely used. Ideal for standard industrial heating applications.

Ceramic Band Heaters

Designed for higher temperatures and longer lifespan. These are energy-efficient and perfect for heavy-duty use.

Mineral Insulated Band Heaters

Built for extreme conditions using magnesium oxide insulation. They offer excellent heat transfer and durability.

Nozzle Band Heaters

Compact and powerful, nozzle heaters are used in injection molding machines for precise melt flow control.

Raw Materials Used in Band Heater Manufacturing

Stainless Steel

The outer shell is made of corrosion-resistant stainless steel to withstand high temperatures and harsh environments.

Mica Insulation

Mica provides excellent electrical insulation and heat resistance.

Ceramic Insulation

Used for higher temperature tolerance and improved energy efficiency.

Nickel-Chromium Resistance Wire

This is the heat-generating core that converts electricity into thermal power.

Step-by-Step Band Heater Manufacturing Process

Design & Engineering

The process starts with dimensions, voltage requirements, watt density, and application needs.

Insulation Placement

Mica or ceramic insulation is layered carefully to ensure safety and heat efficiency.

Element Winding

Resistance wire is wound with extreme precision to ensure uniform heating.

Clamping & Assembly

Steel shells are shaped, clamped, and fitted with terminals.

Quality Testing

Each heater undergoes:

- High-voltage testing

- Resistance checks

- Heat distribution inspection

Only flawless units move forward.

Key Industries That Use Band Heaters

Plastic Injection Molding

Used to melt plastic granules smoothly and consistently.

Extrusion Industry

Ensures uniform heating along long barrels.

Pharmaceutical Machinery

For temperature-sensitive drug processing.

Food Processing Equipment

Helps control heating in packaging and sealing machines.

Packaging Industry

Essential for shrink wrapping and sealing operations.

How to Choose the Right Band Heater Manufacturer

Experience & Expertise

An experienced manufacturer understands heat behavior and machine compatibility.

Customization Capability

Your machines aren’t generic—your heaters shouldn’t be either.

Certifications & Quality Standards

ISO standards and electrical safety certifications matter.

After-Sales Support

Great manufacturers stand by their products with real support.

Importance of Custom Band Heaters

Temperature Accuracy

Custom heaters ensure exact heating without hot spots.

Energy Efficiency

Correct watt density reduces power consumption.

Machine Compatibility

Perfect fit means better heat transfer and longer machine life.

Quality Control in Band Heater Manufacturing

Electrical Safety Testing

Leakage current testing prevents short circuits.

Heat Distribution Checks

Ensures the heater warms evenly around the surface.

Durability & Stress Tests

Heaters are tested under extreme thermal cycles for long-term reliability.

Energy Efficiency & Innovation in Band Heaters

Smart Temperature Sensors

Modern band heaters integrate thermostats and sensors for precise monitoring.

Low Power Consumption Designs

Advanced insulation reduces heat loss by up to 30%.

Export Market & Global Demand

Asia as a Manufacturing Hub

Asia dominates production due to cost efficiency and skilled labor.

Europe & USA Market Demand

High demand for quality-certified industrial heaters.

Common Problems with Low-Quality Band Heaters

Uneven Heating

Leads to product defects and machine damage.

Short Service Life

Cheap materials mean frequent replacement.

Machine Downtime Losses

Poor heaters cause production shutdowns and profit loss.

Cost Factors in Band Heater Manufacturing

Material Quality

Better materials = higher price but longer lifespan.

Custom Design Charges

Custom heaters cost more but save long-term expenses.

Bulk Order Pricing

Large orders reduce per-unit production cost.

OEM & Private Label Band Heater Manufacturing

Benefits of OEM Supply

Manufacturers produce heaters under your brand name.

Branding Opportunities

You control the design, packaging, and market identity.

Future Trends in Band Heater Technology

AI Temperature Control

Smart automation will dominate industrial heating.

Eco-Friendly Materials

Sustainable insulation and recyclable metals are shaping the future.

Why Choosing the Right Band Heater Manufacturer Matters?

Your production line is only as strong as its weakest heating element. Choosing the right manufacturer means:

- Higher efficiency

- Lower maintenance

- Consistent production

- Long-term cost savings

Think of your band heater manufacturer not as a supplier but as an extension of your engineering team.

Conclusion

A band heater may look simple on the outside, but behind its compact design lies complex engineering, precision craftsmanship, and critical industrial value. The right band heater manufacturer doesn’t just create heating devices they create stability, efficiency, and production confidence.

Whether you’re in plastics, packaging, food processing, or pharmaceuticals, investing in high-quality band heaters from a reliable manufacturer is one of the smartest decisions you can make for your business. After all, in industrial production, heat isn’t just power it’s precision.

FAQs

- How long does a band heater typically last?

With proper usage and quality materials, a band heater can last 2–5 years or more. - What is the difference between mica and ceramic band heaters?

Mica heaters are cost-effective, while ceramic heaters offer higher temperature resistance and energy efficiency. - Can band heaters be customized for special machines?

Yes, most professional manufacturers offer complete customization in size, voltage, and wattage. - Are ceramic band heaters more energy-efficient?

Yes, ceramic heaters reduce heat loss and improve energy savings significantly. - What is the biggest cause of band heater failure?

Overheating, poor fit, and low-quality insulation are the most common reasons.