Temperature is the heartbeat of almost every industrial process. Whether you’re melting steel, baking bread, or generating electricity, one small fluctuation can change everything. That’s where thermocouples step in as silent guardians of accuracy. And behind every reliable temperature sensor stands a dependable thermocouple manufacturer.

Think of a thermocouple manufacturer as the architect behind precision. They design, test, and produce sensors that must survive punishing heat, freezing cold, pressure, vibration, and corrosive environments without missing a beat. In this in-depth guide, we’ll walk through everything you need to know about thermocouple manufacturers, their processes, products, challenges, and why choosing the right one is crucial for your business.

Introduction to Thermocouples

What Is a Thermocouple?

A thermocouple is a temperature sensor made by joining two dissimilar metal wires at one end. When that junction experiences heat, it generates a small voltage. That voltage corresponds directly to temperature. Simple? Yes. Powerful? Absolutely.

It’s like a thermometer for harsh industrial worlds where glass thermometers would give up instantly.

How Thermocouples Work

The secret sauce is the See beck effect. When two different metals are joined and exposed to temperature differences, electrons get excited and start moving. This movement creates a measurable voltage. The thermocouple manufacturer calibrates this voltage to match temperature charts with extreme accuracy.

Importance of a Reliable Thermocouple Manufacturer

Accuracy and Safety

In industries like oil & gas or chemical processing, temperature errors aren’t just expensive—they’re dangerous. A trusted thermocouple manufacturer ensures precise readings, reducing the risk of explosions, equipment failure, and product defects.

Long-Term Performance

Cheap thermocouples behave like cheap shoes they fail when you need them most. A reputable manufacturer uses premium alloys, advanced welding, and strict testing to ensure long operational life even in brutal conditions.

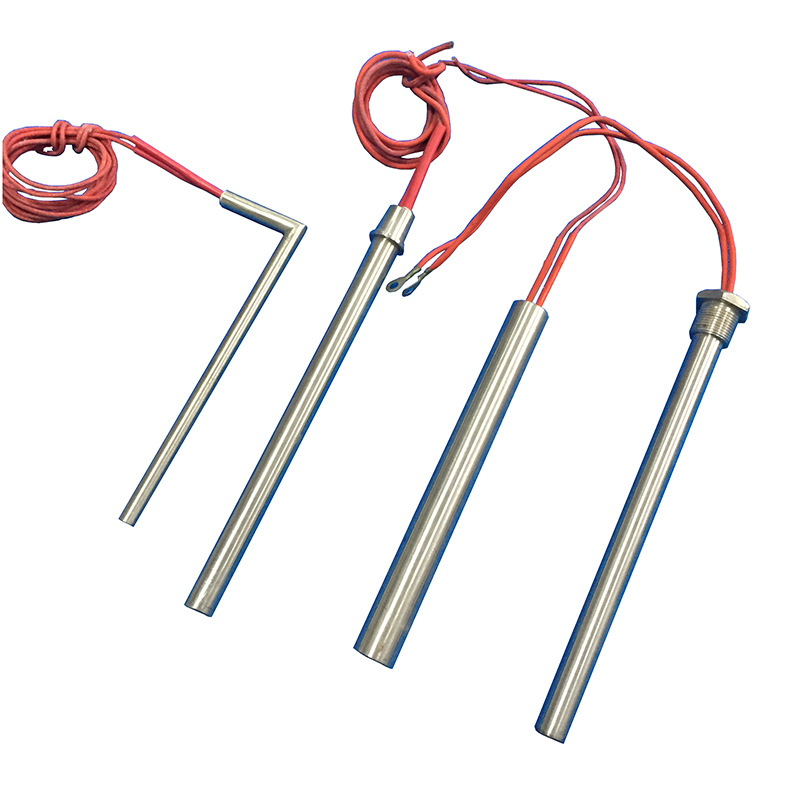

Types of Thermocouples Manufactured Today

Different applications demand different thermocouples. Here’s a breakdown of the most common types produced by manufacturers worldwide:

Type K Thermocouple

The most popular type. Wide temperature range, excellent durability, and affordable pricing. Ideal for furnaces, kilns, and general industrial use.

Type J Thermocouple

Perfect for low-to-medium temperatures. Common in plastic, packaging, and food industries.

Type T Thermocouple

Highly accurate at low temperatures. Frequently used in laboratories and cryogenic applications.

Type N Thermocouple

Designed for stability in high-temperature and oxidizing environments. A modern alternative to Type K.

Type R, S, and B Thermocouples

These are the royalty of thermocouples—made with platinum. They handle extreme heat in steel plants, glass furnaces, and aerospace testing.

Industries That Rely on Thermocouple Manufacturers

Manufacturing and Automation

From CNC machines to injection molding, temperature feedback controls quality and consistency.

Oil and Gas Industry

Drilling operations and refineries operate at extreme conditions. Thermocouples ensure safe and efficient output.

Power Generation

Boilers, turbines, and reactors use thermocouples to keep everything within safe temperature limits.

Food Processing

Cooking, freezing, pasteurization every step must meet strict temperature controls.

Medical and Laboratories

Precision is everything. Even a 1-degree error can destroy an experiment.

Key Materials Used in Thermocouple Manufacturing

Nickel-Based Alloys

Used in Type K, J, and N thermocouples. Strong, corrosion-resistant, and heat-tolerant.

Platinum and Noble Metals

Used in Type R, S, and B. Extremely accurate but costly.

Insulation and Sheathing Materials

Ceramic, fiberglass, PTFE, and stainless steel protect thermocouples from harsh environments.

Manufacturing Process of Thermocouples

Raw Material Selection

Everything begins with precise alloy composition. A tiny impurity can destroy accuracy.

Wire Drawing and Welding

Ultra-thin wires are drawn and welded at micro-level precision.

Insulation and Sheathing

Protective layers make the thermocouple resistant to pressure, moisture, and chemicals.

Calibration and Testing

Every thermocouple is tested against known temperature points to ensure exact readings.

Custom vs Standard Thermocouples

When to Choose Standard Models

Standard models are cost-effective and perfect for general-purpose applications.

Benefits of Custom-Built Thermocouples

Custom sizes, special insulation, rare alloys custom thermocouples are built exactly for your environment.

Quality Standards Followed by Professional Thermocouple Manufacturers

ISO Certification

Guarantees manufacturing quality, traceability, and consistency.

ASTM and IEC Standards

Ensure global compatibility and safety performance.

Role of Calibration in Thermocouple Manufacturing

Why Calibration Matters

Without calibration, a thermocouple is just two wires pretending to be a sensor.

In-House vs Third-Party Calibration

Top manufacturers maintain in-house calibration labs for faster turnaround and better-quality control.

Common Applications of Thermocouples

Furnaces and Kilns

Extreme heat requires rugged and stable sensors.

HVAC Systems

Thermocouples regulate building temperatures and energy efficiency.

Chemical Processing

Accurate temperature prevents dangerous reactions.

Automotive Sector

Used in engines, exhaust systems, and battery management.

Challenges Faced by Thermocouple Manufacturers

High-Temperature Stability

At 1200°C and above, even metals begin to misbehave.

Signal Interference

Electrical noise can distort small voltage signals.

Harsh Environment Performance

Moisture, corrosive gases, vibration everything works against the sensor.

How to Choose the Best Thermocouple Manufacturer

Experience and Expertise

Years in the industry mean fewer mistakes and better consistency.

Customization Capabilities

Not every application fits standard models.

Testing and Certification

Ask for test reports. Real manufacturers love paperwork.

After-Sales Support

The relationship shouldn’t end at delivery.

Global Thermocouple Manufacturing Market Overview

Market Growth Trends

Smart factories and automation are fueling rapid growth.

Emerging Technologies

Wireless sensors, AI-driven monitoring, and real-time cloud data.

Importance of R&D in Thermocouple Manufacturing

Innovation in Material

New alloys improve lifespan and accuracy.

Smart Temperature Sensors

Self-diagnosing thermocouples are becoming a reality.

OEM and Bulk Thermocouple Manufacturing

Benefits for Large Industries

Lower costs, dedicated production lines, and uniform quality.

Cost Optimization

Bulk ordering slashes per-unit price without sacrificing quality.

Environmental and Safety Compliance in Thermocouple Production

RoHS and REACH Compliance

Protecting users and the environment simultaneously.

Eco-Friendly Manufacturing

Recycling metals and reducing production waste.

Future of Thermocouple Manufacturing Industry

AI and Automation Integration

Smart factories powered by robotics and predictive maintenance.

Wireless Temperature Sensing

No wires, instant monitoring, remote diagnostics.

Conclusion

A thermocouple may look like a simple sensor, but behind its performance lies the expertise of a professional thermocouple manufacturer. From raw material selection to precision welding, from calibration to environmental testing, each step determines how accurately and reliably temperature is measured. As industries grow smarter and more automated, the demand for high-quality thermocouples will only intensify. Choosing the right manufacturer today means securing safety, efficiency, and performance for years to come.

FAQs

Q1: What is the lifespan of a thermocouple?

It depends on usage, environment, and material, but high-quality thermocouples can last several years.

Q2: Can thermocouples work in corrosive environments?

Yes, with proper sheathing and insulation materials like Inconel or ceramic.

Q3: Which thermocouple type is the most commonly used?

Type K is the most widely used due to its wide temperature range and affordability.

Q4: Do thermocouples require regular calibration?

Yes, regular calibration ensures long-term accuracy and measurement reliability.

Q5: Can thermocouples be customized for specific machines?

Absolutely. Many manufacturers specialize in fully customized thermocouple solutions.