In today’s fast-moving industrial world, heat plays a silent yet powerful role. From plastic molding to medical equipment, nothing runs smoothly without controlled heating. And right at the heart of these heating systems sits an unsung hero the cartridge heater. If you’ve ever wondered what a cartridge heater manufacturer really does and why this industry is growing so rapidly, you’re in the perfect place.

Let’s break it all down in a simple, real-world way no boring technical overload, just useful, practical knowledge.

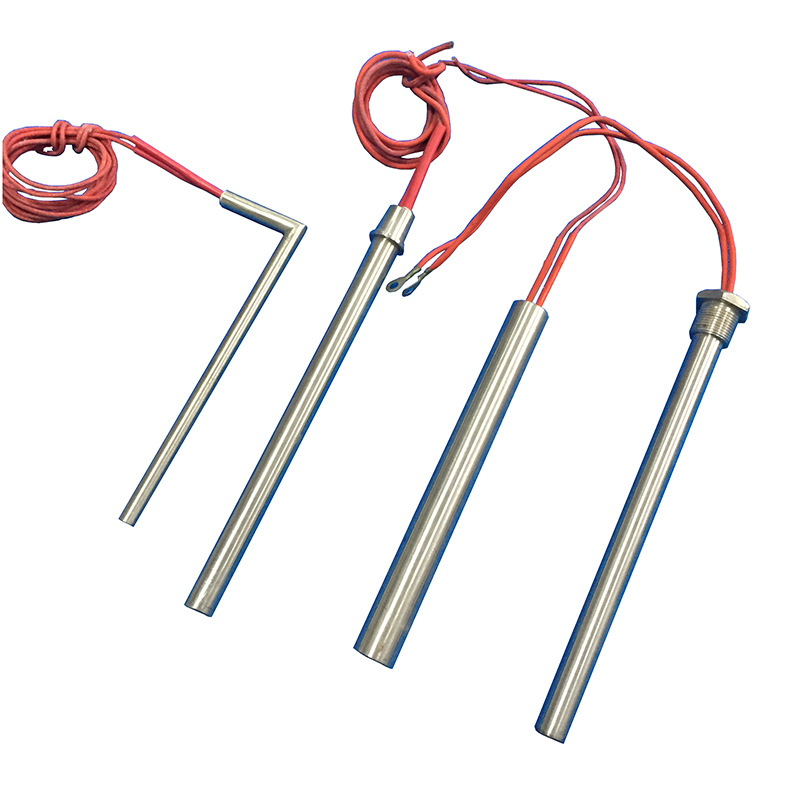

What Is a Cartridge Heater?

Think of a cartridge heater as a compact, powerful electric heater packed into a metal tube. It’s designed to slide right into drilled holes and deliver intense, focused heat exactly where it’s needed.

Basic Working Principle

A cartridge heater works by converting electrical energy into heat using a resistance wire coiled inside a metal sheath. Once powered, it heats up rapidly and transfers that heat directly into the surrounding material.

Key Features of Cartridge Heaters

- High temperature resistance

- Compact and space-saving

- Fast heat-up time

- Extremely durable

Role of a Cartridge Heater Manufacturer

A cartridge heater manufacturer does much more than just “make heaters.” They engineer heat solutions.

Design & Engineering

Manufacturers calculate proper watt density, voltage, and dimensions based on end-use. Every heater is designed for performance and safety.

Material Selection

Premium stainless-steel sheaths, high-purity magnesium oxide insulation, and top-grade resistance wire ensure longevity and efficiency.

Quality Control

From resistance testing to insulation checks, every heater undergoes strict inspections before leaving the facility.

Types of Cartridge Heaters

Different industries demand different heat strengths so manufacturers produce several types.

High-Density Cartridge Heaters

Used in extreme temperature applications like plastic molds and die casting.

Low-Density Cartridge Heaters

Ideal for softer materials where gentle, even heating is needed.

Miniature Cartridge Heaters

Perfect for compact applications like medical devices and lab instruments.

Square Cartridge Heaters

Used when round heaters are not suitable for tight or flat surface installations.

Key Components Used in Cartridge Heaters

Every cartridge heater is built like a carefully layered sandwich.

Heating Wire

Usually made from nickel-chromium alloy for maximum heat resistance.

Magnesium Oxide Insulation

This powder ensures fast heat transfer while keeping electricity safely insulated.

Stainless Steel Sheath

Acts like armor protecting the heater from corrosion and mechanical damage.

Manufacturing Process of Cartridge Heaters

This is where the magic happens.

Coil Winding

Resistance wire is precisely wound to achieve uniform heating.

Insulation Filling

Magnesium oxide powder is packed around the coil for thermal conductivity.

Swaging Process

The heater is compressed under high pressure to remove air gaps and improve heat transfer.

Sealing & Testing

Ends are sealed, leads attached, and each unit is electrically tested for safety.

Industries That Use Cartridge Heaters

Cartridge heaters power countless industries without anyone even noticing.

Plastic & Injection Molding

They heat mold cavities to shape plastic parts perfectly.

Packaging Industry

Used in sealing machines for shrink wrapping and heat sealing.

Medical Equipment

Autoclaves, sterilizers, and diagnostic devices rely on precise heat.

Food Processing

From ovens to warmers, consistent heating keeps food safe and tasty.

Importance of Custom Cartridge Heaters

One-size-fits-all doesn’t work in industrial heating.

Custom Diameters & Lengths

Manufacturers build heaters to exact hole sizes for perfect fit.

Watt Density Customization

Different materials require different heating intensity.

Voltage Customization

From 12V to 480V manufacturers tailor heaters to power systems worldwide.

Global Demand for Cartridge Heater Manufacturers

The world is heating up industrially speaking.

Growth in Automation

More machines mean more heaters simple math.

Rise of Smart Factories

Modern industries want precise, responsive heating systems, driving demand upward.

How to Choose the Right Cartridge Heater Manufacturer

Not all manufacturers are created equal.

Experience & Certification

Look for ISO-certified manufacturers with proven industry experience.

Custom Manufacturing Capabilities

A good manufacturer can design to your exact specs.

After-Sales Support

Heaters are long-term investments. Technical support matters.

Quality Standards in Cartridge Heater Manufacturing

Good heaters follow strict quality rules.

ISO Certifications

Ensure process control and consistency.

Electrical Safety Standards

Guarantee shock protection, insulation strength, and reliable terminals.

Advantages of Buying from a Professional Manufacturer

Why risk cheaper, unreliable options?

Longer Heater Life

Premium materials equal longer operational life.

Energy Efficiency

Proper design reduces power consumption and heat loss.

Application-Specific Performance

Heaters engineered for your application work smarter not harder.

Common Problems Solved by Cartridge Heaters

These small heaters solve big industrial headaches.

Uneven Heating

Cartridge heaters deliver uniform temperature distribution.

Slow Heat-Up Times

They reach target temperatures quickly and efficiently.

Energy Wastage

Direct-contact heating minimizes energy loss.

Future Trends in Cartridge Heater Manufacturing

The future of heating is smarter and greener.

Smart Heating Solutions

Sensor-integrated heaters are entering the market.

Energy-Efficient Designs

Lower power consumption with higher heating efficiency is the goal.

Why Local vs International Cartridge Heater Manufacturers Matter

Choosing between local and overseas suppliers affects your business.

Pricing Difference

International options may be cheaper but hidden costs add up.

Delivery Time

Local manufacturers offer faster turnaround.

Technical Support

On-site support gives local manufacturers a strong advantage.

Environmental Impact & Sustainability

Modern manufacturers are going green.

Eco-Friendly Materials

Recyclable metals and safer insulation materials are being adopted.

Low Energy Consumption

High-efficiency heaters reduce carbon footprints significantly.

Conclusion

Choosing the right cartridge heater manufacturer is not just about buying a product it’s about investing in performance, safety, efficiency, and long-term reliability. Whether you’re in plastic molding, medical equipment, food processing, or automation, a high-quality cartridge heater can make the difference between smooth production and constant breakdowns.

As industries continue to evolve and automation grows stronger, cartridge heaters will only become more essential. Working with an experienced, certified manufacturer ensures that your heating solutions are built to last, save energy, and deliver consistent results day after day.

FAQs

- What is the average lifespan of a cartridge heater?

With proper installation and usage, a high-quality cartridge heater can last anywhere from 3 to 7 years. - Can cartridge heaters be custom-made?

Yes, manufacturers offer full customization in terms of size, voltage, watt density, and lead options. - Are cartridge heaters energy efficient?

Absolutely. Their direct-contact heating design minimizes energy loss. - What temperature can a cartridge heater reach?

Depending on design and materials, temperatures can exceed 800°C. - How do I know if my heater is failing?

Signs include slow heat-up, uneven temperature, frequent tripping, and visible damage to leads.