Let’s start simple. If your machine needs precise, reliable heat in a compact space, chances are it relies on a cartridge heater. These small but powerful heating elements are the unsung heroes inside molds, dies, packaging machines, and medical devices.

Behind every dependable heater is a skilled cartridge heater manufacturer. And choosing the right one? That can mean the difference between smooth production and constant downtime.

So, how do cartridge heaters really work, what should you expect from a manufacturer, and how do you choose the right partner? Let’s break it all down.

What Does a Cartridge Heater Manufacturer Do?

A cartridge heater manufacturer doesn’t just make metal tubes with wires inside. They design, engineer, test, and customize heating solutions for very specific industrial needs.

From selecting the right sheath material to calculating watt density and insulation, manufacturers ensure each heater delivers:

- Accurate temperature control

- Long service life

- Safe electrical performance

- Consistent heating

In other words, they don’t sell products. They deliver reliability.

Why Cartridge Heaters Matter in Modern Industry

Imagine an injection molding machine that can’t maintain stable temperature. Or a sealing machine that overheats and damages packaging. Sounds expensive, right?

Cartridge heaters provide:

- Fast heat-up times

- Uniform heat distribution

- Compact installation

- Precise temperature control

That’s why industries trust them in high-performance and high-precision applications.

How Cartridge Heaters Work

At their core, cartridge heaters convert electrical energy into heat through resistance wire.

Here’s the simple process:

- Electricity flows through resistance wire

- The wire heats up due to electrical resistance

- Heat transfers through insulation

- The metal sheath delivers heat to the application

It’s simple physics, perfected by smart engineering.

Core Components of a Cartridge Heater

A high-quality cartridge heater typically includes:

- Resistance wire for heat generation

- Magnesium oxide insulation for electrical safety and thermal transfer

- Metal sheath for protection and heat delivery

- Lead wires or terminals for electrical connection

Each component plays a critical role in performance and lifespan.

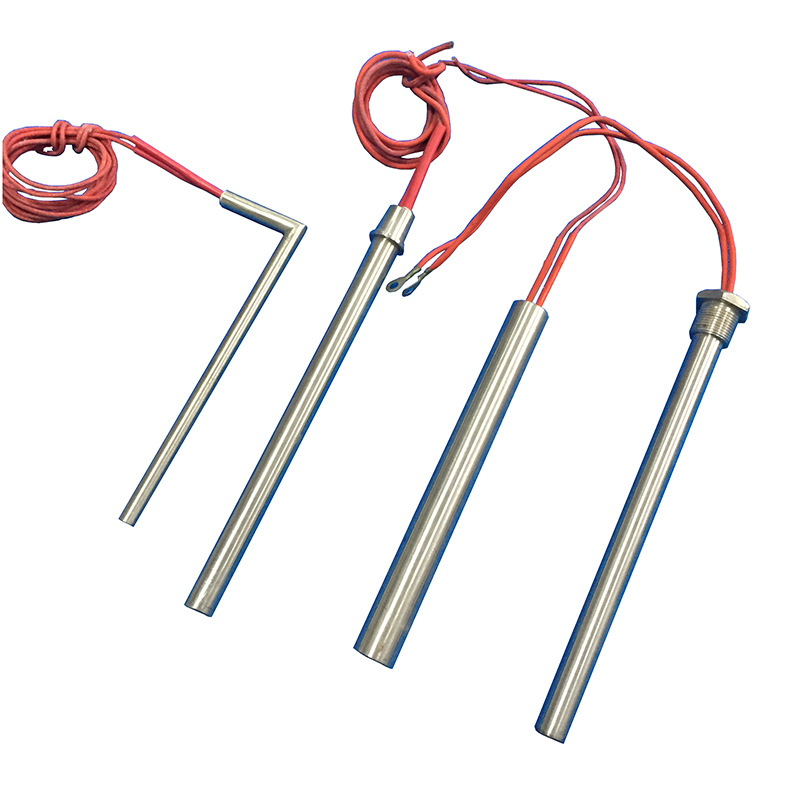

Types of Cartridge Heaters

Not all cartridge heaters are created equal. Manufacturers usually offer:

- Low-density cartridge heaters

- Medium-density cartridge heaters

- High-density cartridge heaters

- Swaged cartridge heaters

- Square or rectangular heaters for special slots

Choosing the right type depends on temperature, space, and watt density.

How to Choose the Right Cartridge Heater Manufacturer

Now we’re getting to the important part. Not all manufacturers offer the same quality or service.

Quality Standards and Certifications

Always check for:

- ISO certifications

- Compliance with international electrical standards

- Documented quality systems

Certifications show discipline. And discipline shows reliability.

Customization Capabilities

Standard heaters don’t always fit. A good manufacturer should offer:

- Custom diameters and lengths

- Special voltages and watt densities

- Unique lead configurations

If they can’t customize, they can’t optimize.

Engineering Support and Design Services

Great manufacturers don’t just take orders. They ask questions.

They help you select:

- Proper watt density

- Correct sheath material

- Right insulation for your environment

That engineering support saves you from expensive mistakes.

Production Capacity and Lead Times

Ask yourself:

- Can they handle large volumes?

- Can they deliver on time?

- Do they keep stock for urgent needs?

Delays in heaters often mean delays in production.

Materials and Technology Used in Cartridge Heaters

Materials matter more than most people realize.

Sheath Materials Explained

Common sheath materials include:

- Stainless steel

- Incoloy

- Copper

Each material handles heat, corrosion, and pressure differently.

Resistance Wire and Insulation

High-quality resistance wire ensures:

- Stable heating

- Long life

- Minimal drift over time

Magnesium oxide insulation provides both electrical safety and excellent thermal transfer.

Advanced Manufacturing Techniques

Modern manufacturers use:

- Precision swaging

- Automated winding

- Computer-controlled testing

Technology improves consistency and reduces defects.

Customization Options Offered by Manufacturers

Customization is where great manufacturers shine.

Voltage and Watt Density Options

You can choose:

- Low watt density for long life

- High watt density for fast heating

- Special voltages for unique systems

This flexibility improves both performance and durability.

Diameter and Length Variations

Manufacturers can produce heaters:

- From very thin to thick diameters

- Short or extra-long lengths

- Straight or bent designs

This allows perfect fitting into any application.

Lead Wire and Termination Styles

Options include:

- Fiberglass leads

- Stainless steel braid

- Screw terminals

- Ceramic caps

Each option suits a different environment.

Quality Control and Testing Processes

This is where good manufacturers separate themselves from average ones.

Electrical Testing

Before shipment, heaters are tested for:

- Insulation resistance

- Continuity

- Voltage integrity

This prevents dangerous electrical failures.

Thermal Performance Testing

Manufacturers check:

- Heat output accuracy

- Uniform temperature distribution

- Stability under load

Heat that drifts is heat you can’t trust.

Long-Term Reliability Checks

Some manufacturers perform:

- Life cycle testing

- High-temperature endurance tests

- Vibration testing

Because real-world conditions are harsh.

Global vs Local Cartridge Heater Manufacturers

Should you buy local or global? There’s no single right answer.

Advantages of Local Manufacturing

Local suppliers offer:

- Faster delivery

- Easier communication

- Better after-sales support

They’re often ideal for urgent or customized orders.

Benefits of Global Suppliers

Global manufacturers may provide:

- Lower costs

- Large-scale production

- Wide product catalogs

They’re useful for high-volume standard heaters.

Cost Factors in Cartridge Heater Manufacturing

Why do prices vary so much?

Material Costs

Premium materials increase:

- Durability

- Temperature limits

- Corrosion resistance

Cheap materials reduce life expectancy.

Design Complexity

Custom designs require:

- Engineering time

- Special tooling

- Extra testing

That adds to cost, but also to performance.

Order Volume Impact

Large orders often mean:

- Lower unit prices

- Better delivery priority

- Long-term supply agreements

Volume matters in pricing.

Future Trends in Cartridge Heater Manufacturing

The industry isn’t standing still.

Energy-Efficient Designs

Manufacturers are developing:

- Lower power loss designs

- Better insulation

- Optimized watt density

Efficiency saves energy and money.

Smart Heating Solutions

Some heaters now include:

- Built-in sensors

- Smart temperature monitoring

- Predictive maintenance features

Welcome to the era of intelligent heating.

Sustainable Manufacturing

Eco-friendly practices include:

- Reduced waste

- Recyclable materials

- Energy-efficient production

Sustainability is becoming a competitive advantage.

Conclusion

Choosing the right cartridge heater manufacturer isn’t just a purchasing decision. It’s a strategic one.

The right partner delivers:

- Reliable performance

- Custom-engineered solutions

- Long product life

- Strong technical support

In a world where downtime costs money, quality heating is an investment, not an expense.

Choose wisely, and your machines will thank you.

FAQs

- What is the typical lifespan of a cartridge heater?

With proper design and installation, a quality cartridge heater can last several years, even in high-temperature applications. - Can cartridge heaters be customized for special machines?

Yes, most manufacturers offer full customization for size, voltage, watt density, and terminations. - How do I select the correct watt density?

It depends on temperature, material, and heat transfer conditions. A manufacturer’s engineer can help calculate it. - Are cartridge heaters safe for continuous operation?

Yes, when properly designed and installed, they are made for continuous industrial use. - Should I choose a local or international manufacturer?

Choose based on lead time, support needs, customization, and cost. Both options have advantages.