Description

Manufacturing process:

put coil heating wires through the seamless steel pipe, copper or aluminum tube, Using filling machine more to fill insulation and thermal oxidation object evenly in the gaps,such as Crystal magnesium oxide powder (alumina or clean quartz sand are all available) etc.,And then use shrink tube machine contract pipe diameter, make oxide medium dense(make density achieves above 3.3 g/cm3),Ensure the heating wire cut off from the air, the center position touch pipe wall and don’t offset.It can increase heating power more than ten times per unit area.the using life can be improved to more than 10 years,Comparing with large heating power electric element ,tubular heaters can save 5% material,Thermal efficiency can reach above 90%.

Application:

1 Semiconductor chamber heating

2 Semiconductor wafer lead connection

3 Semiconductor wire and die bonding

4 Freeze protection and deicing of equipment in cold climates or applications

5 Humidity Control

6 Patient Comfort heating used in medical devices

7 Mold die and platen heating

8 Seal bars used in packaging equipment

9 Test sample heating in gas chromatography

Characteristics & Properties

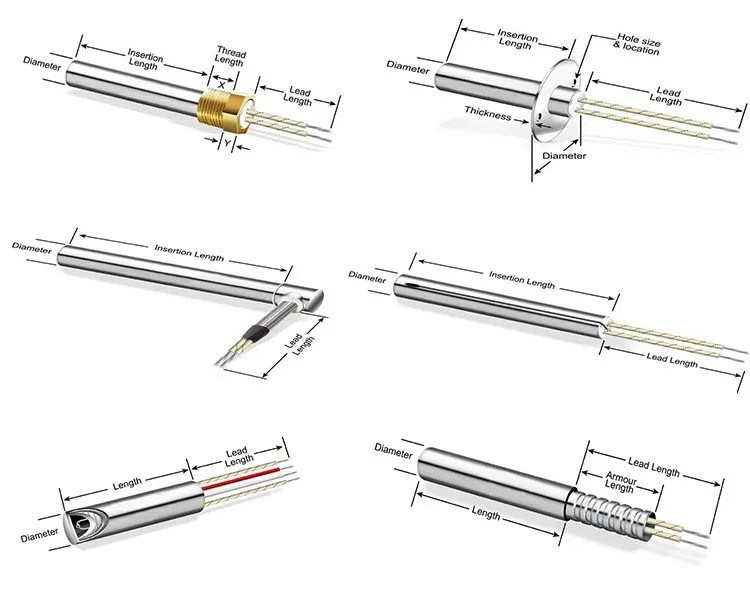

Tube diameter: Φ2mm-Φ30mm

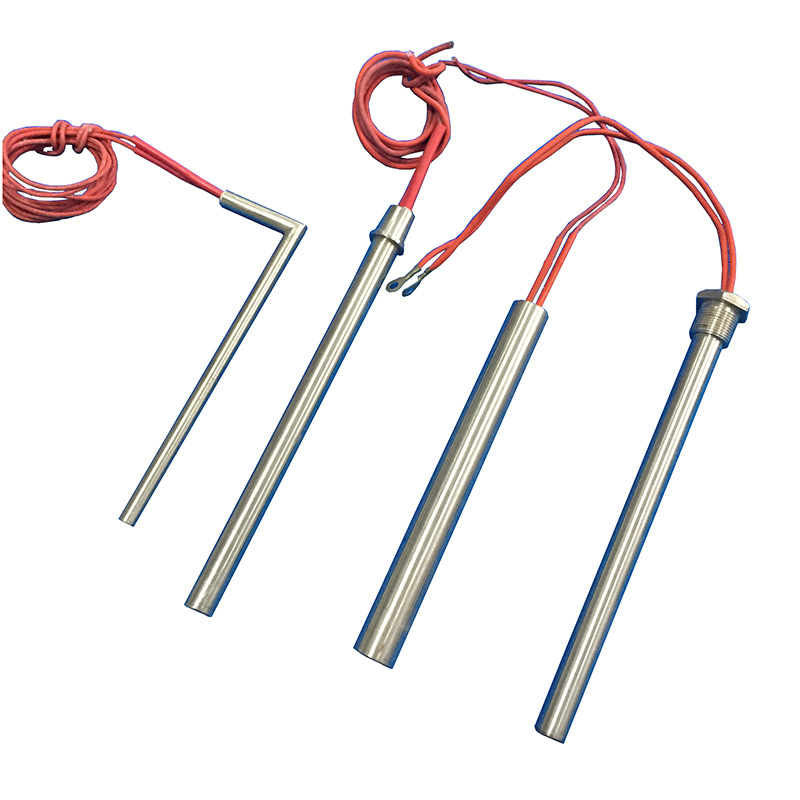

Tube Material: SS201, SS304, SS316, SS321 and INCOLOY800 etc

Insulation Material: MgO

Conductor Material: Nichrome Resistance Wire

Wattage Density: High/Middle/Low (5-25w/cm2)

Lead Connection Option: Threaded Stud Terminal or Lead Wire

Lead Wire Type: 300mm Standard (Teflon/Silicone High Temperature Fiberglass are available for cartridge electric heater)

Advantages

internal wiring: high temperature resistance, uniform heating, high thermal conductivity and difficult

cable fracture.

external wiring: high temperature resistance, uniform heating and high thermal conductivity.

Date sheets

|

Resistance heating wire |

NiCr 80/20 wire |

|

Wattage Tolerance |

+5%, -10% |

|

Resistance tolerance |

+10%, -5% |

|

Length tolerance |

±1 mm |

|

Diameter tolerance |

± 0.02mm |

|

Standard Cold Zone |

5-10mm |

|

Insulation resistance (cold) |

≥ 500 MΩ |

|

Maximum leakage current (cold) |

≤ 0.5 mA |

|

Thermocouple Location |

type J / K / Ground wire |