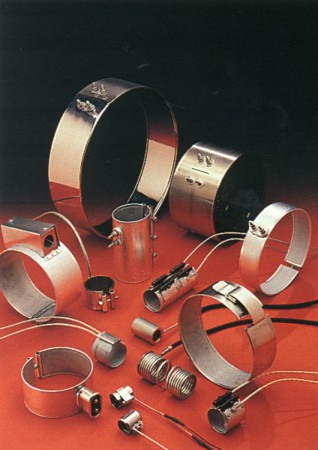

5 Things to Consider When Choosing the Right Mica Band Heater for Your Application

Mica band heaters are versatile and reliable heating elements used in various industrial processes. They efficiently transfer heat to cylindrical objects by wrapping around them like a band. Choosing the right mica band heater for your application is crucial for optimal performance and safety. Here are 5 key factors to consider: Size and Wattage: Diameter and Length: Measure the diameter and length of the object you want to heat. Mica band heaters come in various sizes to ensure proper fit and even heat distribution. Wattage and Heating Requirements: Consider the desired heating speed and temperature range for your application. Higher-wattage heaters generate more heat faster, while lower-wattage options provide gentler heating. Termination Styles: Mica band heaters offer different termination styles for electrical connection: Lead Wire Terminations: These heaters have exposed lead wires for connection to a terminal block or control panel. They are simple to install but require proper wiring expertise. Terminal Box Terminations: These heaters come with a built-in terminal box for secure and protected electrical connections. They offer a safer and more finished look. Plug and Play Options: Some mica band heaters come with pre-wired plugs for easy connection to a standard power outlet. This is ideal for low-voltage applications that don’t require complex controls. Material and Construction: Heating Element: Most mica band heaters use a nickel-chromium resistance wire for heating. This material offers durability, high-temperature resistance, and efficient heat generation. Insulation: Mica, a naturally occurring mineral, is a common insulator in mica band heaters. It provides excellent heat resistance and electrical insulation. Outer Shell: The outer shell protects the heating element and insulation. Stainless steel is a popular choice for its durability and resistance to corrosion. Temperature Control: Thermocouple Compatibility: Some mica band heaters come with built-in thermocouples for temperature sensing. Ensure your heater and control system are compatible for accurate temperature monitoring. External Controllers: For precise temperature control, consider using an external temperature controller with your mica band heater. This allows for setting and maintaining specific target temperatures. Application Considerations: Environment: Think about the environment where you’ll use the heater. For harsh environments with moisture or chemicals, consider options with special coatings or enclosures for added protection. Safety Features: Some mica band heaters offer built-in safety features like thermostats or fuses to prevent overheating. These features are crucial for applications requiring precise temperature control or using flammable materials. Additional Features: Multiple Heat Zones: Certain mica band heaters have multiple heating zones for controlled heating of different sections of a cylindrical object. Customizable Options: Many manufacturers offer a custom mica band heater tailored to specific size, wattage, and termination requirements. Wrap Up By considering these 5 factors, you can select the ideal mica band heater for your application. Remember, consulting with a reputable mica band heater supplier can provide valuable guidance and ensure you get the right heater for your needs. They can answer your questions, recommend suitable options, and even offer custom solutions if needed.

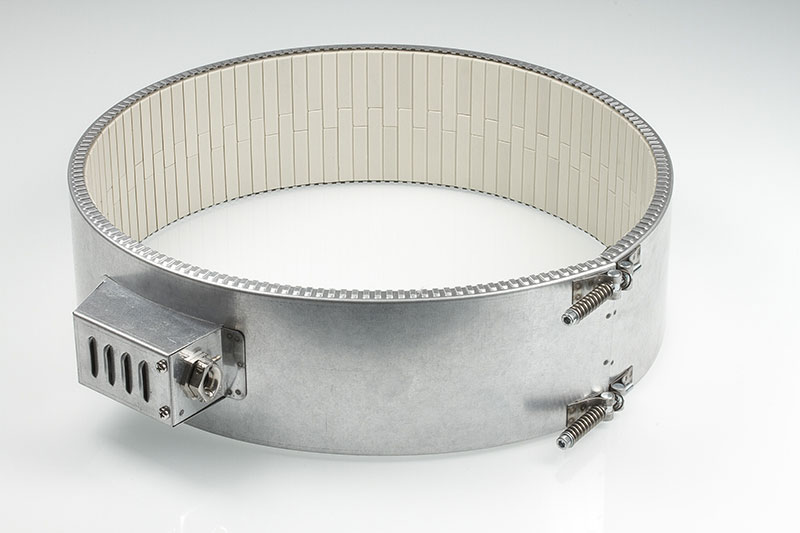

3 Key Benefits of Using a Ceramic Band Heater Over Traditional Heating Elements

A ceramic band heater is rapidly becoming the go-to choice for a wide range of industrial heating applications. These versatile heating elements offer several advantages over traditional methods like open flame heating or radiant heaters. If you’re looking for a more efficient, reliable, and uniform heating solution, then ceramic band heaters might be the perfect fit for your needs. Let’s explore the top 3 benefits of using a quality ceramic band heater: Superior Heat Transfer and Efficiency: Even Heat Distribution: Ceramic band heaters are designed to wrap around pipes, tubes, or vessels, providing 360-degree heat distribution. This ensures a consistent and uniform heating process, eliminating hot spots and cold zones commonly found with other methods. Reduced Energy Consumption: The efficient design of ceramic band heaters minimizes heat loss to the surrounding environment. This translates to lower energy consumption and cost savings on your heating operations. Fast Heating Up Times: Ceramic band heaters have excellent thermal conductivity, allowing them to reach desired temperatures quickly. This minimizes downtime and improves overall production efficiency. Here’s a table summarizing the efficiency benefits of ceramic band heaters: Benefit Description Even Heat Distribution 360-degree heating eliminates hot spots and cold zones. Reduced Energy Consumption Minimizes heat loss for lower energy costs. Fast Heating Up Times Reaches desired temperatures quickly for improved efficiency. Exceptional Durability and Long Lifespan: High-Temperature Resistance: Every ceramic band heater is built with robust ceramic material that can withstand high operating temperatures. This makes them ideal for a variety of industrial applications involving hot melts, adhesives, or other heat-intensive processes. Chemical Resistance: The ceramic material in these heaters is resistant to many chemicals and solvents commonly encountered in industrial settings. This reduces the risk of damage or corrosion, extending the lifespan of the heater. Rugged Construction: Ceramic band heaters are built to last. The sturdy construction can handle demanding industrial environments and frequent heating cycles. Here’s a table summarizing the durability benefits of a ceramic band heater: Benefit Description High-Temperature Resistance Withstands high operating temperatures for various applications. Chemical Resistance Resists chemicals and solvents commonly found in industrial settings. Rugged Construction Built to last for demanding industrial environments and frequent use. Precise Temperature Control and Versatility: Integrated Thermocouples: Many ceramic band heaters come equipped with built-in thermocouples. These sensors allow for precise temperature control and monitoring, ensuring consistent and accurate heating processes. Wide Range of Sizes and Wattages: Ceramic band heaters come in a variety of sizes and wattages to accommodate a wide range of heating requirements. You can find the perfect heater size and power output for your specific application. Easy Installation and Maintenance: Ceramic band heaters are typically easy to install and maintain. Their flexible design allows for them to be wrapped around objects of various shapes and sizes. Additionally, the robust construction minimizes the need for frequent replacements. Here’s a table summarizing the versatility benefits of a ceramic band heater: Benefit Description Integrated Thermocouples Allows for precise temperature control and monitoring. Wide Range of Sizes and Wattages Accommodates various heating requirements for different applications. Easy Installation and Maintenance Simple installation and minimal maintenance needs. Last Word If you’re looking for a reliable heating solution for your industrial applications, then a quality ceramic band heater is worth considering. Its superior heat transfer, exceptional durability, and precise temperature control make it a valuable asset for various industries.

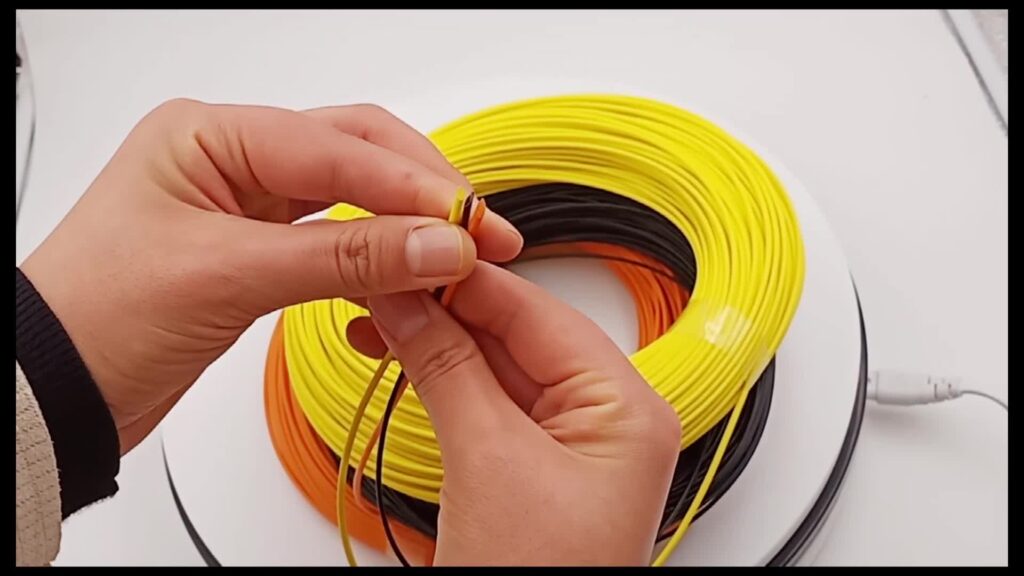

5 Benefits of Using Silicone Fiberglass Cable in High-Temperature Applications

Silicone fiberglass cable is becoming increasingly popular for applications that deal with extreme heat. Unlike traditional cable insulation materials that melt or become brittle at high temperatures, silicone fiberglass cables offer exceptional heat resistance, making them a reliable and safe choice for various demanding environments. Let’s explore the five key benefits of using a silicone fiberglass cable in high-temperature applications: Exceptional Heat Resistance: The primary advantage of silicone fiberglass cables is their ability to withstand scorching temperatures. Here’s a breakdown: Silicone Rubber Insulation: Silicone rubber, the core insulator in these cables, boasts remarkable thermal stability. It can continuously operate at temperatures ranging from -60°C (-76°F) to a staggering +200°C (+392°F). Fiberglass Braid: The additional layer of fiberglass braid further enhances heat resistance. Fiberglass inherently possesses excellent thermal insulation properties. This exceptional heat tolerance makes silicone fiberglass cables ideal for various high-temperature applications, including: Industrial Ovens and Furnaces: These cables can withstand the intense heat generated by industrial ovens and furnaces, ensuring reliable power delivery to control systems and monitoring equipment. Power Generation: In power plants, silicone fiberglass cables can be used for critical connections near boilers, turbines, and other heat-generating machinery. Welding Equipment: These cables can handle the high heat associated with welding processes, providing safe and reliable power for welding tools. Superior Flame Retardance: Safety is paramount, especially when dealing with high temperatures. Silicone fiberglass cables excel in this area: Self-Extinguishing: Silicone rubber is a self-extinguishing material. This means it won’t continue burning once the source of ignition is removed, minimizing fire risks. Low Smoke Emission: In the unlikely event of a fire, silicone fiberglass cables generate minimal smoke, improving visibility and reducing the risk of inhalation hazards. These flame-retardant properties make silicone fiberglass cables perfect for applications where fire safety is crucial, such as: Aerospace and Defense Industries: These cables are used in aircraft and military equipment due to their ability to withstand extreme temperatures and minimize fire risks. Mass Transit Systems: In trains, buses, and other mass transit vehicles, silicone fiberglass cables can be used for critical electrical connections where fire safety is a top priority. Building Construction: These cables can be used in high-rise buildings and other structures with stringent fire safety regulations. Enhanced Flexibility and Durability: Silicone fiberglass cables offer a winning combination of flexibility and resilience: Silicone Rubber: Silicone rubber is known for its elasticity, allowing for easy cable routing and installation, even in tight spaces. This flexibility is maintained even at high temperatures. Fiberglass Braid: While offering heat resistance, the fiberglass braid also provides structural reinforcement, making the cable more resistant to wear and tear. This unique blend of flexibility and durability makes silicone fiberglass cables well-suited for: Robotics and Automation: The flexibility allows for easy integration into robotic arms and automated machinery that move in various directions. Medical Equipment: These cables can be used in medical devices that require movement and manipulation without compromising performance or safety. Harsh Environments: The durability of these cables makes them suitable for harsh environments with exposure to dust, moisture, and vibrations. Chemical Resistance: Many high-temperature environments also involve exposure to harsh chemicals. Silicone fiberglass cables can handle these challenges: Silicone Rubber: Silicone rubber exhibits excellent resistance to a wide range of chemicals, including oils, solvents, and acids. This resistance prevents cable degradation and ensures reliable performance. This chemical resistance makes silicone fiberglass cables a great choice for: Chemical Processing Plants: These cables can be used for control systems and equipment monitoring in chemical plants where exposure to various chemicals is a constant factor. Oil and Gas Industry: In refineries and other oil and gas facilities, silicone fiberglass cables can withstand exposure to oils and other chemicals without degrading. Food Processing Facilities: The chemical resistance makes these cables suitable for use near food processing equipment where hygiene and sanitation are paramount. Long Service Life: Silicone fiberglass cables are built to last: Heat and Flame Resistance: The exceptional heat and flame resistance of these cables contribute to a longer lifespan. They can withstand high temperatures and harsh environments without degrading quickly. Durability and Chemical Resistance: The durability and chemical resistance properties further extend the service life of these cables. They can endure wear and tear, chemical exposure, and maintain reliable performance for extended periods.

5 Applications of an RTD Sensor in Industrial Temperature Measurement

RTD sensor (Resistance Temperature Detector) is a workhorse in the world of industrial temperature measurement. These reliable and accurate sensors play a vital role in various industrial processes, ensuring smooth operation and product quality. But how exactly are RTD sensors used? Let’s explore five key applications of an industrial RTD sensor: Oil and Gas Industry: Accurate Monitoring in Refineries: RTD sensors are crucial in oil refineries, monitoring temperatures throughout the refining process. From crude oil distillation to product storage, precise temperature control is essential for safety, efficiency, and product quality. Pipeline Temperature Monitoring: An RTD sensor ensures the safe and efficient transportation of oil and gas products by monitoring pipeline temperatures. This helps prevent leaks, explosions, and product degradation during transportation. Chemical and Pharmaceutical Manufacturing: Reaction Vessel Temperature Control: Chemical reactions are often highly sensitive to temperature. RTD sensors provide accurate temperature readings in reaction vessels, ensuring precise control and consistent product quality. Maintaining Sterile Environments: In pharmaceutical manufacturing, maintaining sterile environments is critical. RTD sensors monitor temperatures in sterilization chambers and cleanrooms, ensuring they reach and maintain the required levels for effective sterilization. Power Generation: Optimizing Power Plant Efficiency: RTD sensor plays a vital role in power plants by monitoring temperatures in boilers, turbines, and other critical equipment. This data helps ensure optimal efficiency and prevent equipment failure. Combustion Control: For efficient and clean power generation, precise control of combustion temperatures is essential. RTD sensors provide real-time temperature data in the combustion chamber, allowing operators to optimize fuel burning and minimize emissions. Food and Beverage Production: Ensuring Food Safety: Maintaining proper temperatures during food processing is crucial for safety and preventing spoilage. RTD sensors monitor temperatures in ovens, freezers, pasteurizers, and other food processing equipment. Maintaining Product Quality: Temperature control plays a significant role in maintaining the taste, texture, and overall quality of food and beverage products. RTD sensors help ensure consistent temperatures throughout production processes. Building Automation and HVAC Systems: Maintaining Comfortable Building Temperatures: RTD sensors are used in thermostats and building automation systems to monitor and regulate indoor air temperature. This ensures a comfortable environment for occupants while optimizing energy consumption. Process Cooling in Industrial Settings: Many industrial processes generate significant heat. RTD sensors monitor temperatures in cooling systems like chillers and air conditioning units, ensuring they function properly and maintain optimal operating temperatures. Benefits of Using RTD Sensors: High Accuracy: RTD sensors offer excellent accuracy over a wide temperature range, making them reliable for critical industrial applications. Wide Range of Options: RTD sensors come in various configurations and materials to suit diverse temperature measurement needs in different industrial settings. Stable Performance: RTD sensors exhibit stable performance over time, ensuring consistent and reliable temperature readings. Durable Construction: Industrial-grade RTD sensors are built to withstand harsh environments and demanding industrial applications. Relatively Simple Design: The basic design of RTD sensors makes them relatively easy to install, maintain, and calibrate. Wrap Up RTD sensor is a versatile and valuable tool for industrial temperature measurement. Its combination of accuracy, reliability, and durability makes it a preferred choice for various applications across diverse industries. By understanding different applications and choosing the right RTD sensor, you can ensure precise temperature control, optimize processes, and achieve consistent product quality in your industrial setting.

5 Essential Things to Know Before Installing MI Heating Cables

MI heating cables, also known as mineral-insulated heating cables, are a reliable and efficient way to prevent freezing and maintain consistent temperatures in pipes and vessels. But before you install one yourself, it’s crucial to understand these cables and the process. Here are 5 essential things to know before installing MI heating cables: Understanding MI Heating Cable Basics: Construction: MI heating cables consist of a heating element encased in a mineral insulation layer, all protected by a durable metallic sheath. This design ensures safe and efficient heat distribution while withstanding harsh environments. Applications: MI heating cables are commonly used in residential and commercial settings to prevent freezing in pipes carrying water, oils, or other liquids. They can also maintain desired temperatures in vessels for process control applications. Safety Features: MI heating cables come with built-in grounding conductors and are often flame-retardant, providing additional safety during operation. Choosing the Right MI Heating Cable: Selecting the right MI heating cable depends on several factors: Pipe Size and Material: MI heating cables come in various diameters to fit snugly around different pipe sizes. The cable’s wattage (heat output) also needs to be sufficient for your pipe material (metal pipes require higher wattage than plastic). Application Temperature: Consider the desired temperature you want to maintain in your pipes or vessel. Choose a cable with enough wattage to reach and maintain that temperature effectively. Length Requirements: Measure the length of the pipe or vessel needing heating to determine the required cable length. Remember to factor in some extra length for connection purposes. Regulatory Requirements: In some regions, specific approvals or certifications might be necessary for MI heating cables used in certain applications. Check with local building codes or consult a qualified electrician for guidance. Planning and Preparation for Installation: Proper planning is key for a successful and safe MI heating cable installation: Turn Off Power: Always turn off the power supply to the affected pipes or equipment before starting the installation process. Clear the Work Area: Clear the workspace around the pipes to allow for easy cable placement and connection. Gather Tools and Materials: Have all the necessary tools and materials on hand, including the MI heating cable, cable ties, insulation tape, thermostat (if needed), and appropriate cutting tools. Read and Understand Instructions: Carefully read and understand the manufacturer’s instructions for your specific MI heating cable model. This ensures proper installation and safe operation. Installation Tips and Techniques: Here are some key points to remember during MI heating cable installation: Maintain Minimum Bending Radius: Avoid bending the cable too sharply. Respect the minimum bending radius specified by the manufacturer to prevent damage to the internal heating element. Secure the Cable Properly: Use cable ties or straps to securely fasten the MI heating cable along the pipe or vessel at regular intervals. Ensure a snug fit but avoid over-tightening. Terminate the Cable Ends: MI heating cables require proper termination at both ends for connection to a power source and thermostat (if used). Consult a qualified electrician if unsure about cable termination techniques. Insulate the System: After installing the cable, apply appropriate thermal insulation around the pipes or vessel to minimize heat loss and improve energy efficiency. Safety Precautions and Considerations: Safety is paramount when working with electrical components like MI heating cables: Leave Electrical Work to Professionals: If you’re uncomfortable with electrical work, consider hiring a licensed electrician for installation. They have the expertise and experience for safe and proper cable installation. Double-Check Connections: Before turning on the power, double-check all electrical connections to ensure they are secure and made according to the manufacturer’s instructions. Grounded System: Ensure the MI heating cable system is properly grounded to prevent electrical hazards. Consult an electrician for grounding requirements if needed. Test and Maintain: Once installed, test the MI heating cable system to verify its functionality. Regularly inspect the cable and connections for any signs of damage and perform maintenance as the manufacturer recommends. Wrap Up By understanding these essential points, you can approach your MI heating cable installation project with confidence. Remember, consulting a qualified electrician is always the safest and most reliable option for complex installations or if you lack electrical expertise. They can ensure a professional installation that meets all safety standards and code requirements.