5 Best Applications of a Warm Floor Cable

A warm floor cable is an essential component for efficient underfloor heating systems. It provides consistent and cost-effective heating, ensuring comfort in residential, commercial, and industrial spaces. Unlike traditional heating systems, these cables work seamlessly beneath the flooring, offering even heat distribution. With the rising demand for energy-efficient solutions, let’s uncover the top applications of a warm floor cable and their advantages across different scenarios. 1. Residential Floor Heating Systems Warm floor cables are widely used in homes to create comfortable and cozy living spaces. Their ability to provide consistent warmth makes them ideal for cold climates or areas with harsh winters. Key uses include: Bathroom Heating: These cables are perfect for ensuring warm floors in bathrooms, eliminating the discomfort of stepping onto cold tiles during winter mornings. Living Room Comfort: They help create evenly heated living spaces without the need for bulky radiators or forced air systems. Energy Efficiency: Homes with warm floor cables can reduce heating costs by up to 30% compared to conventional systems. Warm floor cable also enhances property value by offering an energy-efficient, modern heating solution. 2. Commercial Applications In commercial buildings, warm floor cables provide heating solutions that are both efficient and discreet. They work well in areas where large heating systems may be impractical: Retail Spaces: Warm floor cables keep customer areas comfortable, especially in high-traffic locations. Hotels: They improve guest experiences by offering heated floors in lobbies, bathrooms, and spa areas. Offices: In workspaces, these cables maintain a consistent temperature, increasing productivity and reducing energy costs. 3. Industrial Use Cases Warm floor cables are not just for comfort—they’re also functional in industrial settings. They offer solutions for challenges such as frost protection and maintaining specific floor temperatures. Common industrial uses include: Warehouses: These cables prevent freezing on warehouse floors, ensuring safe working conditions. Factories: In manufacturing, warm floor cables help maintain optimal temperatures for certain processes or materials. Cold Storage Facilities: They prevent frost damage and ensure temperature-sensitive items are stored safely. Industrial applications benefit significantly from the durability and efficiency of warm floor cables, which reduce maintenance and downtime. 4. Frost Protection for Outdoor Spaces Warm floor cables can also be installed outdoors to prevent frost and ice buildup. This application is especially important for ensuring safety and convenience in winter months. Typical uses include: Driveways: Keep driveways ice-free to prevent accidents and improve vehicle traction. Walkways and Stairs: Ensure safe pedestrian access by melting snow and ice on outdoor pathways. Loading Docks: In commercial areas, warm floor cables ensure smooth operations during freezing conditions. This type of installation is both practical and cost-efficient, minimizing risks and the need for constant manual de-icing. 5. Underfloor Heating in Renovation Projects For renovations, warm floor cables are an excellent way to upgrade old heating systems. They integrate easily into modern flooring designs and improve the overall energy efficiency of older buildings. Benefits for renovation projects include: Retrofitting in Existing Homes: Warm floor cables can be installed beneath various flooring types, including tiles, laminate, and hardwood. Space Optimization: They eliminate the need for visible heaters, freeing up space for aesthetic and functional purposes. Improved Energy Ratings: Homes and commercial properties with underfloor heating often achieve higher energy performance ratings. Final Words Warm floor cables are a versatile and energy-efficient solution for modern heating needs. Whether you’re upgrading your home, enhancing safety in outdoor spaces, or improving commercial heating systems, these cables provide unmatched performance.

What is a MI Heat Trace Cable?

Industrial heating systems rely heavily on advanced solutions like the MI heating cable to ensure efficiency, safety, and precision. Known for their robust construction and ability to deliver consistent heat in challenging environments, MI heating cables are a critical component in applications ranging from petrochemical plants to food processing facilities. Let’s take an in-depth look at what makes MI heating cables indispensable, their functionality, and their unique benefits. What is an MI Heating Cable? A Mineral Insulated (MI) heating cable is a highly durable electric heating cable used for maintaining or raising temperatures in pipes, tanks, and industrial equipment. Unlike conventional heating cables, MI heating cables consist of a metallic sheath and mineral insulation (typically magnesium oxide), which protect the heating elements from moisture, corrosion, and mechanical damage. This robust design ensures unmatched performance in extreme conditions, such as high temperatures, high-pressure environments, and exposure to chemicals. These features make MI heating cables a preferred choice for critical industries like oil and gas, pharmaceuticals, and chemical processing. How Does an MI Heating Cable Work? The working principle of an MI heating cable is simple yet efficient. It uses resistance heating to generate heat: Electrical current flows through the heating element within the cable. Heat is generated by resistance, which is then evenly distributed across the surface. The mineral insulation ensures maximum thermal conductivity while protecting the heating core. This construction allows MI heating cables to operate reliably at temperatures exceeding 1,000°C (1,832°F), far surpassing the capabilities of polymer-based heating cables. Key Features of MI Heating Cables MI heating cables stand out due to their unique design and capabilities. Here’s what sets them apart: High Temperature Tolerance: With the ability to operate at extreme temperatures, these cables ensure stable performance in demanding environments. Corrosion Resistance: The metallic sheath and mineral insulation provide excellent resistance to moisture, chemicals, and other corrosive elements. Durability: The rugged design prevents damage from mechanical stress, ensuring a long operational life. Precision Heating: These cables deliver uniform heat, making them ideal for applications requiring consistent thermal control. Common Applications of MI Heating Cables MI heating cables are versatile and serve a wide range of industrial and commercial applications, including: Freeze Protection: Preventing pipework and tanks from freezing in cold climates. Process Temperature Maintenance: Ensuring stable temperatures for chemical reactions and fluid transfer in industrial systems. Tank Heating: Maintaining product temperatures in storage tanks, especially in oil and gas facilities. Floor Heating: Providing underfloor heating in high-end architectural projects. Why MI Heating Cables Are Critical for Modern Industries MI heating cables offer several advantages that make them irreplaceable in many sectors: Energy Efficiency: Reduced energy loss due to excellent thermal conductivity. Safety Compliance: Meets stringent safety standards for hazardous and non-hazardous environments. Customizability: Tailored solutions for specific lengths, wattages, and voltage ratings. Longevity: With minimal maintenance, they outperform traditional cables in terms of lifespan. Final Thoughts The MI heating cable is a technological marvel designed to meet the most demanding industrial heating needs. Its durability, high-temperature tolerance, and versatility make it an essential solution for industries requiring reliable heat management systems. For businesses looking to optimize performance and safety, MI heating cables provide unmatched efficiency and peace of mind.

3 Top Benefits of Mica Heat Proof Cable Box

Choosing the right materials for electrical insulation is critical in high-temperature environments. One solution stands out for its durability and safety—the mica heat proof cable box. This essential component is transforming industrial and residential wiring by providing unmatched resistance to heat and electrical hazards. Below, we break down the top benefits of this innovative technology. 1. Unmatched Heat Resistance The primary advantage of a mica heat proof cable box lies in its ability to withstand extreme temperatures. Here’s why this matters: Thermal Stability: Mica can endure temperatures up to 1000°C without compromising performance. This makes it ideal for industrial settings with high heat exposure. Safety Enhancement: The box prevents heat transfer to surrounding components, reducing the risk of fire and system failures. Prolonged Lifespan: Unlike traditional materials, mica doesn’t degrade when exposed to heat over long periods, ensuring consistent functionality. Industries such as power generation, steel manufacturing, and aerospace rely heavily on these boxes to maintain operational safety. Even in residential applications, they provide an added layer of protection against overheating and electrical faults. 2. Exceptional Electrical Insulation Another game-changing benefit is its superior electrical insulation. Mica is a naturally dielectric material, making it an ideal choice for safe electrical installations. Minimal Current Leakage: It offers high dielectric strength, minimizing power loss and preventing hazardous current leaks. Resistance to Arc Faults: Mica remains stable under electrical arcing conditions, a common hazard in high-voltage systems. High Voltage Handling: It supports voltage levels of up to 1500V, ensuring reliability even in heavy-duty environments. This ensures that sensitive equipment and wiring remain unaffected, promoting operational efficiency and reducing maintenance costs. 3. Environmental and Cost Efficiency In addition to safety, mica heat proof cable boxes contribute to environmental and financial sustainability. Here’s how: Eco-Friendly: Mica is a naturally occurring mineral, free from harmful chemicals, and easily recyclable. This minimizes its environmental footprint. Reduced Energy Consumption: Its insulating properties prevent energy loss, lowering electricity usage in both industrial and residential systems. Low Maintenance Costs: With its resistance to wear and tear, mica boxes require fewer repairs and replacements, reducing long-term expenses. Moreover, its durability ensures that infrastructure upgrades are needed less frequently, making it a cost-effective solution for businesses aiming to optimize their operations. Key Applications of Mica Heat Proof Cable Box This versatile product is used across multiple industries due to its unique properties: Industrial Furnaces: Ensures safe wiring in high-temperature zones. Electric Vehicles (EVs): Protects against heat and electrical overload in advanced battery systems. Construction: Enhances fire safety in modern building wiring systems. Final Thoughts The mica heat proof cable box is more than just a component—it’s a necessity in environments where safety and durability are non-negotiable. Its heat resistance, insulation capabilities, and cost efficiency make it a smart choice for both industrial and residential applications. By investing in this technology, businesses and homeowners can ensure long-term safety, reliability, and sustainability. When choosing materials for your electrical systems, prioritize solutions that deliver proven performance. The mica heat proof cable box is a benchmark in innovation and reliability.

How to Use Immersion Tubular Heater

Immersion tubular heaters are indispensable in industries and households for their efficiency and reliability. Whether you’re looking to heat liquids, oils, or even gases, these heaters offer a cost-effective solution. However, understanding the right way to use an immersion tubular heater is essential to maximize performance and extend the equipment’s lifespan. This guide provides actionable steps and facts to help you make the most of your heater. What Is an Immersion Tubular Heater? An immersion tubular heater is a versatile heating element designed to be directly immersed in a medium—usually liquid or gas. The heat generated by the element is efficiently transferred, making it ideal for applications requiring rapid and consistent heating. Common industries that rely on these heaters include: Chemical processing: For heating chemicals and solutions. Food and beverage: To maintain safe processing temperatures. Water treatment: For sterilizing and heating water. Manufacturing: For heating oils, fuels, and other materials. Step-by-Step Guide: How to Use an Immersion Tubular Heater 1. Understand the Specifications Before using an immersion tubular heater, check its specifications: Voltage and wattage ratings. Material compatibility (stainless steel, Incoloy, or titanium for corrosive environments). Maximum operating temperature and pressure. 2. Prepare the Medium Ensure the liquid or gas being heated is free from debris. Particles can adhere to the heater, causing inefficient heating or damage over time. For water heating: Use filtered or soft water to minimize scaling. For chemicals: Verify the heater’s material compatibility to avoid corrosion. For oils: Ensure the oil’s viscosity is suitable for the heater’s power output. 3. Correct Placement Submerge the heater entirely in the medium to avoid dry firing. Maintain the recommended clearance around the element for even heat distribution. Use mounting brackets if required to secure the heater. Warning: Operating an immersion tubular heater outside the medium can cause overheating and failure. 4. Monitor Temperature Always use a thermostat or temperature controller to regulate the heating process. Overheating can damage both the heater and the medium. Set the thermostat to a safe operating range. Monitor temperature changes to prevent overheating accidents. 5. Perform Regular Maintenance Routine maintenance ensures your heater remains efficient and safe. Inspect for scaling or residue buildup regularly. Clean the heater with non-corrosive solutions. Replace worn-out components like gaskets or seals. Key Benefits of Proper Use Using an immersion tubular heater correctly delivers: Reduced energy costs due to efficient heat transfer. Increased lifespan of the heater through proper maintenance. Improved safety by minimizing risks of overheating or damage. Latest Trends in Immersion Tubular Heaters Smart controllers: Integration with IoT devices for remote monitoring and control. Eco-friendly materials: Manufacturers are focusing on recyclable and sustainable components. Enhanced corrosion resistance: New alloys like Inconel 825 improve longevity in harsh environments. Last Word An immersion tubular heater is a versatile and efficient tool when used correctly. By following the steps outlined—preparation, placement, temperature monitoring, and maintenance—you can ensure safe and effective operation. Invest time in understanding the specifications and stay updated with the latest trends to get the best out of your heater. With proper care, this equipment can provide years of reliable service. Ready to heat smarter and safer? Start applying these tips today!

What Is Finned Tubular Heater Used For?

A finned tubular heater is a highly efficient heating solution widely used across industries due to its enhanced heat transfer capabilities. These heaters combine a tubular element with metal fins to increase surface area, enabling faster heat dissipation. But what exactly are they used for? Let’s break it down with actionable insights and practical applications. How Does a Finned Tubular Heater Works? Before understanding its uses, let’s clarify how it operates. A finned tubular heater works by converting electrical energy into heat. The fins attached to the heating element improve thermal conductivity and airflow, making the heater ideal for high-demand environments. Key benefits of its design include: Improved heat transfer through the fins. Durable materials like stainless steel or Incoloy for harsh conditions. Customizable configurations to suit diverse applications. This unique functionality makes the finned tubular heater indispensable in various settings. Common Uses of Finned Tubular Heater 1. Industrial Drying Applications Industries requiring controlled drying processes rely heavily on these heaters. Their precise temperature control ensures consistent results, making them ideal for: Drying textiles, paper, and wood. Baking coatings and adhesives. Removing moisture in packaging processes. Why it works: The extended surface area increases airflow efficiency, reducing drying times. 2. HVAC Systems Heating, Ventilation, and Air Conditioning (HVAC) systems benefit from the finned tubular heater’s ability to quickly heat large air volumes. These heaters are commonly found in: Duct heating systems. Air handlers for commercial spaces. Residential heating units. Pro Tip: They reduce energy consumption compared to traditional heaters, cutting operational costs. 3. Food and Beverage Industry Food safety regulations demand precise temperature control, and finned tubular heaters deliver just that. They are used for: Cooking and baking equipment. Sterilization of utensils and machinery. Keeping food warm in buffet setups. Their durability ensures consistent performance, even under continuous operation. 4. Chemical and Pharmaceutical Processing In sensitive environments like chemical plants and labs, heating needs to be efficient and reliable. Finned tubular heaters excel in: Heating tanks and vats. Maintaining the right temperatures for chemical reactions. Providing uniform heat for lab equipment. Their corrosion-resistant materials handle aggressive chemicals effortlessly. 5. Freezing Prevention in Cold Climates Preventing freezing in pipes and equipment is crucial for industries operating in extreme weather. Finned tubular heaters are used for: Heating pipelines and valves. Defrosting refrigeration units. Protecting critical systems in oil rigs and outdoor machinery. Their rugged construction withstands low temperatures while ensuring uninterrupted operations. Factors to Consider When Choosing a Finned Tubular Heater Selecting the right heater requires evaluating your specific needs. Here’s what to keep in mind: Watt density: Higher watt density is better for industrial tasks, while lower is ideal for gentle heating. Material compatibility: Choose materials like stainless steel for moisture-prone environments. Size and configuration: Match the heater size to the available space for optimal performance. Voltage requirements: Ensure compatibility with your power supply. Final Words A finned tubular heater is a versatile heating solution trusted across industries for its efficiency, reliability, and adaptability. Whether drying, heating air, or safeguarding equipment, these heaters prove invaluable in diverse applications. Understanding their features and benefits ensures you make the right choice for your specific needs.

What is Electric Tubular Heater for Greenhouse?

Heating a greenhouse efficiently is crucial for plant growth, especially during colder months. An electric tubular heater offers a reliable and cost-effective solution. These heaters are specifically designed to maintain consistent temperatures, ensuring plants thrive regardless of external weather conditions. This article explains what an electric tubular heater is, how it works, and why it’s an excellent choice for greenhouse heating. We’ll also highlight the latest features and provide actionable tips for greenhouse owners. What is an Electric Tubular Heater? An electric tubular heater is a slim, energy-efficient device designed to produce uniform heat. It consists of a tubular heating element, often made from stainless steel or other durable materials. Key Features: Consistent Heating: Provides even heat distribution, preventing cold spots. Energy Efficiency: Consumes less energy compared to traditional heaters. Compact Design: Fits easily in smaller greenhouses or under benches. Customizable Options: Available in different lengths and power ratings to suit varying greenhouse sizes. Why Are Electric Tubular Heaters Ideal for Greenhouses? Greenhouses require a steady temperature to support plant growth. Drastic temperature drops can stress plants, stunt growth, or even lead to crop loss. Electric tubular heaters address these challenges effectively. Advantages for Greenhouses: Uniform Temperature Control: Prevents frost damage. Ensures optimal conditions for seed germination and plant growth. Cost-Effectiveness: Lower running costs compared to propane or kerosene heaters. Ideal for long-term use due to energy efficiency. Safety Features: Overheat protection to avoid accidental damage. Waterproof and corrosion-resistant designs for humid environments. Low Maintenance: Requires minimal upkeep, saving time and resources. How Does an Electric Tubular Heater Work? An electric tubular heater converts electrical energy into heat using a resistance wire embedded in a metallic tube. This tube is insulated and sealed, making it safe for greenhouse use. Operational Details: Heat Transfer: The heater emits radiant heat, warming the surrounding air evenly. Thermostat Integration: Most models include thermostats for precise temperature control. Mounting Options: Can be mounted on walls, floors, or benches for flexible installation. Latest Innovations in Electric Tubular Heaters Manufacturers have introduced advanced features to enhance the performance of electric tubular heaters for greenhouses: Smart Temperature Control: Wi-Fi-enabled thermostats for remote adjustments. Eco-Friendly Options: Models designed to reduce carbon footprints with improved efficiency. Adjustable Power Settings: Allows users to switch between energy modes for different seasons. Durable Construction: Enhanced materials for longer life in humid greenhouse environments. Tips for Using an Electric Tubular Heater in a Greenhouse Maximizing the efficiency of your heater ensures better results and lower energy bills. Here are actionable tips: Calculate the Right Heater Size: Use a heating calculator to determine the required wattage for your greenhouse size. Position Strategically: Place the heater near vulnerable areas like doors or windows where heat loss occurs. Pair with Insulation: Use bubble wrap or thermal screens to retain heat inside the greenhouse. Monitor Regularly: Check the thermostat settings and clean the heater periodically to maintain efficiency. Final Thoughts An electric tubular heater for greenhouse is more than just a heating device; it’s a reliable partner in ensuring your greenhouse thrives. With the latest advancements and practical usage tips, you can achieve optimal plant growth while reducing energy consumption. Take the step toward better greenhouse management today with this innovative heating solution!

How Do a Ceramic Radiant Tube Heater Work?

A ceramic radiant tube heater is an efficient and advanced heating solution often found in industrial and commercial settings. Its design leverages radiant heat transfer to deliver warmth effectively, making it a popular choice for high-performance applications. But how does it function, and what sets it apart from other heating systems? Let’s break down the science, components, and real-world advantages of these heaters. The Science Behind Radiant Heating At its core, a ceramic radiant tube heater operates on the principle of radiant heat transfer. Unlike convection heaters that warm the air, radiant heaters emit infrared energy, directly heating objects and surfaces within their range. This ensures targeted and efficient heating, reducing energy waste. Infrared Radiation: These heaters produce infrared waves, which travel through the air without heating it. Direct Heating: The energy is absorbed by objects and people, making it ideal for localized heating needs. Efficiency: Radiant heat reduces energy loss in large, open spaces, a key reason for its widespread use. Key Components of a Ceramic Radiant Tube Heater Understanding how these heaters work requires a look at their essential components: Ceramic Emitter Made from high-grade ceramic, the emitter is the core heating element. It can withstand extreme temperatures, ensuring durability and efficiency. Radiant Tube Usually made from heat-resistant metal alloys, the tube channels the infrared energy. Its reflective properties enhance heat distribution. Gas or Electric Power Source The heater may use natural gas, propane, or electricity. Gas-fired systems burn fuel to heat the ceramic emitter, while electric models use resistive heating. Reflectors Positioned behind the radiant tube, reflectors focus and direct the heat. This design minimizes energy loss and maximizes heat delivery. Control Systems Advanced models feature digital thermostats and smart controls. These allow precise temperature adjustments, reducing operational costs. Benefits of a Ceramic Radiant Tube Heater 1. Energy Efficiency Ceramic radiant tube heaters excel in reducing energy consumption. By directly heating objects instead of air, they eliminate unnecessary heat loss, especially in large, poorly insulated areas. Up to 30% lower energy costs compared to conventional systems. Ideal for warehouses, factories, and outdoor areas. 2. Enhanced Durability The ceramic materials used in these heaters are highly resistant to wear and thermal stress, making them suitable for demanding environments. Long service life with minimal maintenance. Consistent performance even in extreme temperatures. 3. Comfortable and Uniform Heating Radiant heat provides even warmth without creating air currents. This ensures a more comfortable environment for occupants and machinery alike. No dust or allergens stirred up, promoting better air quality. Perfect for precision industries requiring stable temperatures. Practical Applications of Ceramic Radiant Tube Heaters These heaters are used in a variety of settings: Industrial Spaces: Factories and workshops benefit from efficient heating of specific zones. Commercial Buildings: Showrooms, restaurants, and retail stores use them for targeted warmth. Outdoor Areas: Patios and open-air venues rely on radiant heaters for consistent heat in colder months. Specialized Industries: Used in paint drying, food processing, and even aviation for de-icing purposes. How to Choose the Right Ceramic Radiant Tube Heater When selecting a ceramic radiant tube heater, consider the following factors: Size and Heating Capacity Match the heater’s output (measured in BTUs or kW) to the area size. Fuel Type Determine if natural gas, propane, or electric models are most suitable for your facility. Installation Requirements Ensure the heater fits your space constraints and complies with safety standards. Control Options Look for models with programmable thermostats or smart controls for better energy management. Last Word A ceramic radiant tube heater offers an effective and energy-efficient way to provide warmth in industrial and commercial spaces. Its reliance on radiant heat transfer ensures precise and consistent heating, reducing energy costs and improving comfort. Whether you’re looking to heat a warehouse, outdoor area, or a specialized facility, these heaters deliver unmatched performance. By understanding how they work and selecting the right model for your needs, you can achieve optimal heating with minimal energy waste.

5 Unique Facts About Tubular Heater Greenhouse

Heating a greenhouse efficiently is critical for plant health and energy savings. A tubular heater is an excellent solution, providing consistent, low-cost warmth. Greenhouse enthusiasts often overlook the potential of this compact heating option. However, beyond its efficiency, there are fascinating and lesser-known facts about using a tubular heater greenhouse setup that can enhance both productivity and sustainability. Here are five unique insights to maximize its benefits. 1. Energy Efficiency That Cuts Costs Dramatically Tubular heaters are designed for low-energy consumption, making them one of the most economical heating solutions for greenhouses. A standard tubular heater uses between 60 to 120 watts of power per foot, significantly lower than fan heaters or radiant systems. Why this matters: Reduced electricity bills: Greenhouses using tubular heaters can save up to 40% compared to conventional electric heating systems. Consistent temperature: They deliver uniform heat distribution, avoiding hotspots that can damage delicate plants. Eco-friendliness: Less energy consumption means a smaller carbon footprint, aligning with sustainable practices. Quick tip: Position your tubular heater near the base of your plants to create a gentle heat rise. This placement prevents temperature extremes and optimizes energy use. 2. Prevention of Frost Damage One of the standout benefits of tubular heaters is their ability to protect plants from frost during cold spells. Unlike other heating systems, their gentle warmth prevents condensation buildup that leads to freezing. Frost-prevention features: 24/7 operation: Most tubular heaters are designed for continuous use, ensuring no sudden temperature drops. Temperature control: Integrated thermostats allow you to maintain an ideal microclimate for frost-sensitive plants like tomatoes and orchids. By installing a tubular heater, you can extend your growing season and safeguard plants against sudden weather changes. 3. Safety Features Make Them Ideal for Enclosed Spaces Unlike traditional heaters, tubular heaters are engineered with safety in mind, making them perfect for confined greenhouse environments. Built-in safety advantages: Low surface temperature: Tubular heaters remain warm but not hot enough to ignite nearby materials. Moisture resistance: Most models are rated IPX4 or higher, ensuring they can withstand greenhouse humidity without malfunctioning. Automatic shutoff: Many tubular heaters include overheat protection, minimizing fire risks. For greenhouses with limited ventilation, these safety measures make tubular heaters a reliable choice. 4. Customizable to Any Greenhouse Size Tubular heaters are modular, meaning you can configure them to suit any greenhouse size or layout. Whether you have a compact backyard setup or a sprawling commercial operation, these heaters can adapt seamlessly. Customization tips: Length options: Tubular heaters are available in sizes ranging from 2 feet to 8 feet. Choose longer models for larger spaces. Link multiple units: Connect multiple heaters to create a network of even heat distribution. Wall-mount or freestanding: Flexible installation options ensure optimal placement for any greenhouse design. This adaptability allows you to scale your heating solution as your greenhouse expands. 5. Longevity and Low Maintenance Investing in a tubular heater is cost-effective in the long run due to its durability and minimal upkeep requirements. What makes them last: Robust construction: Most tubular heaters are built with corrosion-resistant aluminum or stainless steel, ensuring long-term performance in humid conditions. Simple maintenance: Occasional cleaning is all that’s required to keep them functioning optimally. Warranty coverage: Many reputable brands offer warranties ranging from 3 to 5 years, reflecting their reliability. Greenhouse owners can depend on tubular heaters for years without worrying about frequent replacements or high repair costs. Summary of benefits: Significant energy savings Frost prevention for extended growing seasons Enhanced safety for greenhouse environments Scalability for various greenhouse sizes Durable and low-maintenance heating Key Takeaways A tubular heater greenhouse is not just about keeping plants warm. It’s a smart, energy-efficient, and customizable solution that enhances plant health, protects against frost, and reduces operational costs. Final Words To maximize your greenhouse’s potential, invest in a tubular heater that aligns with your specific needs. With its unique advantages, it’s an asset for any grower striving for efficiency and sustainability.

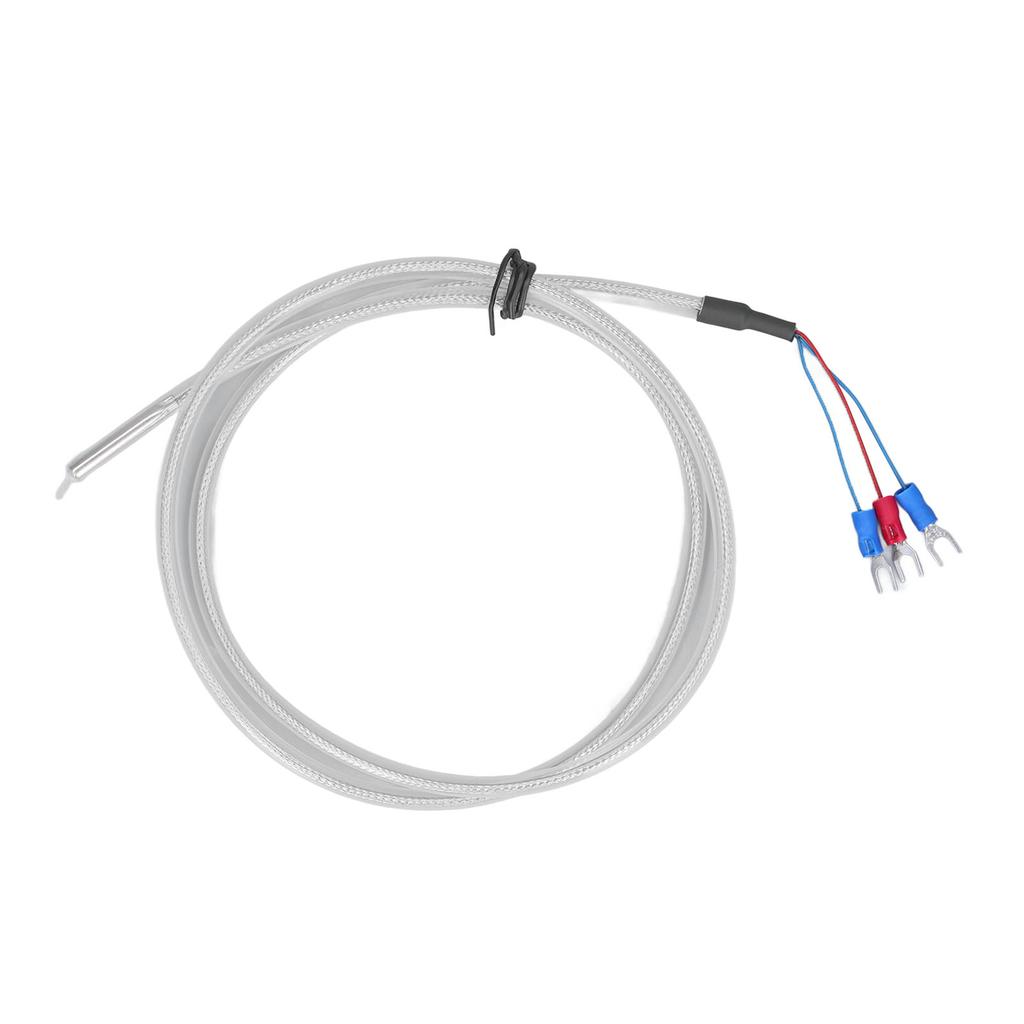

5 Top Benefits of a Thermocouple

A thermocouple is one of the most reliable tools for measuring temperature in industrial and scientific applications. Known for its durability and precision, it is an essential component across industries like aerospace, automotive, and manufacturing. Whether you’re monitoring extreme heat in a furnace or tracking cooling rates in food processing, thermocouples provide accurate data critical for success. Let’s explore the five key benefits of a thermocouple that makes it indispensable. 1. Wide Temperature Range One of the biggest advantages of a thermocouple is its ability to measure temperatures across a vast range. From cryogenic levels as low as -250°C to extreme heat exceeding 2,300°C, thermocouples outperform most alternatives: Type K Thermocouple: The most commonly used, ideal for temperatures ranging from -200°C to 1,260°C. Type S Thermocouple: Accurate at temperatures above 1,500°C, making it suitable for metallurgy and glass production. This versatility allows industries to rely on thermocouples for diverse processes without switching between instruments. 2. Fast Response Time Thermocouple is designed for real-time temperature readings. They respond instantly to temperature changes due to their compact size and direct contact with the environment being measured. In applications like chemical reactors and gas turbines, rapid readings ensure safety and process efficiency. The absence of lag makes thermocouples ideal for dynamic systems where constant monitoring is essential. This speed gives industries the ability to make quick decisions, minimizing risks and optimizing outcomes. 3. Durability in Harsh Environments Industries often require equipment that can withstand harsh and extreme conditions. Thermocouple is built to perform reliably under such circumstances: Corrosion Resistance: Made with robust materials like stainless steel and Inconel, thermocouples resist damage in chemically aggressive environments. Shock and Vibration Tolerance: Used in engines and turbines, thermocouple continues to deliver accurate readings under constant mechanical stress. Their rugged design makes them an excellent choice for heavy-duty industries like oil and gas and aerospace. 4. Cost-Effective Solution Thermocouple offers an excellent balance between performance and affordability. Their simple construction and wide availability keep manufacturing costs low. Low Maintenance Requirements: Unlike other temperature sensors, thermocouples are durable and often require minimal upkeep. Longevity: A properly installed thermocouple can last for years, reducing the need for frequent replacements. This makes them a practical option for businesses looking to manage costs while maintaining operational efficiency. 5. Compatibility with Advanced Systems Thermocouples integrate seamlessly with modern monitoring systems. They are compatible with: Digital Displays: For easy temperature tracking. Data Loggers: Useful for recording temperatures over time. Automated Controls: Essential for precision manufacturing and process optimization. This adaptability ensures thermocouple remains relevant as industries advance technologically. Real-World Applications of a Thermocouple Furnace Monitoring: Ensures temperature consistency in metal and ceramic production. HVAC Systems: Maintains optimal heating and cooling performance. Food Processing: Tracks cooking and freezing conditions for quality control. Their reliability and versatility make thermocouples a preferred choice across these sectors. Final Words A thermocouple is more than just a temperature sensor; it’s a key to precision, efficiency, and safety in industrial and scientific processes. Its unmatched temperature range, quick responsiveness, and adaptability make it a must-have tool. For industries looking to improve operations while keeping costs under control, thermocouples are the perfect solution.

5 Reasons Why a Silicone Rubber Heater is a Must in Industrial Manufacturing

The silicone rubber heater is an essential tool for industries that demand efficient, reliable, and precise heating solutions. Known for its flexibility and durability, this heater stands out in applications where traditional heating elements fall short. Whether in aerospace, medical equipment, or food processing, its unique capabilities make it a critical component in industrial manufacturing. Below, we uncover the top five reasons why the silicone rubber heater is indispensable in this field. 1. Flexibility for Custom Applications The silicone rubber heater is designed for versatility, making it suitable for complex and irregular surfaces. Flexible Construction: Its silicone-based material allows it to bend and conform to different shapes. This makes it ideal for applications like pipes, tanks, and curved equipment surfaces. Custom Sizing and Wattage: Manufacturers can customize the size and watt density to meet specific industrial requirements, ensuring optimal heat distribution and efficiency. This adaptability ensures consistent heating performance even in unconventional setups, reducing the risk of uneven heating or system failures. 2. Durability in Extreme Conditions Industrial environments often subject heating systems to harsh conditions. The silicone rubber heater excels in durability. Temperature Resistance: It operates effectively in a wide range of temperatures, from -60°C to 230°C, ensuring reliability in both freezing and high-heat scenarios. Moisture and Chemical Resistance: Its silicone outer layer protects it from water, chemicals, and environmental exposure, making it highly dependable in humid or corrosive settings. This resilience reduces maintenance needs and extends the heater’s lifespan, even in demanding applications such as medical autoclaves and industrial ovens. 3. Energy Efficiency and Cost Savings Energy efficiency is critical in manufacturing, and the silicone rubber heater delivers on this front. Rapid Heat-Up Time: Its thin and lightweight design allows for faster heating, reducing energy consumption. Precision Heating: Built-in sensors, such as thermocouples, ensure precise temperature control, minimizing energy waste and overheating risks. These features contribute to significant operational cost savings, especially in industries like food processing and pharmaceutical manufacturing, where energy efficiency is a priority. 4. Lightweight and Easy Installation Traditional heaters can be bulky and difficult to install, but the silicone rubber heater offers a lightweight and user-friendly solution. Low Profile: Its slim design makes it easy to integrate into existing systems without requiring significant modifications. Simple Adhesion Options: Many heaters come with self-adhesive backing or mechanical fastening options, ensuring quick and secure installation. This ease of setup reduces downtime, making it a practical choice for industries that demand efficiency and minimal interruptions. 5. Versatility Across Industries The silicone rubber heater is a versatile solution that serves a wide range of industrial sectors. Aerospace: Ensures precise heating in critical components like de-icing systems and fuel lines. Automotive: Keeps batteries warm in electric vehicles for optimal performance during cold weather. Medical: Provides reliable heating in laboratory equipment and patient care devices. This adaptability ensures that manufacturers across industries benefit from its innovative design and capabilities. Final Thoughts A silicone rubber heater is not just another heating element; it’s a critical tool for improving manufacturing efficiency and reliability. Its flexibility, durability, and energy efficiency make it an unmatched solution for industries worldwide. Whether you’re working with precision medical devices or high-capacity industrial systems, this heater is a game-changer for modern manufacturing.