What is the Principle of Immersion Tubular Heater?

An immersion tubular heater is an efficient, compact, and widely used solution for heating liquids, gases, and other substances in various industries. Understanding its principle is crucial for selecting and maintaining heating solutions in industrial and residential settings. Unlike traditional heating methods, immersion tubular heaters provide direct and targeted heating, making them energy-efficient and reliable. Let’s break down the core principles and key applications to help you maximize their potential. The Core Principle of an Immersion Tubular Heater At its core, the immersion tubular heater operates on the principle of electrical resistance. Here’s how it works: Electrical energy is converted into heat. When electric current flows through a resistive heating element (often made of alloys like nichrome), it generates heat. Direct immersion enhances heat transfer. The tubular heater is submerged in the medium it’s designed to heat (such as water, oil, or chemicals). This eliminates heat loss commonly associated with indirect methods. Uniform heating is achieved. The tubular design ensures even distribution of heat across the medium, preventing hot spots or uneven temperatures. Key Components of an Immersion Tubular Heater Sheath Material: Protects the heating element from corrosion. Common options include stainless steel, titanium, or Incoloy, chosen based on the medium being heated. Heating Element: The core component, responsible for generating heat through resistance. Insulation: Separates the element from the sheath to ensure safety and efficiency. Mounting Options: These include flanged, threaded, or over-the-side designs, catering to diverse applications. Applications of Immersion Tubular Heater These heaters play a vital role across industries due to their versatility and efficiency. Here are some common uses: Industrial Processing: Used in chemical tanks, oil refineries, and water treatment plants for precise temperature control. HVAC Systems: Provides supplemental heat for air-handling units. Food and Beverage Industry: Ensures optimal temperatures in cooking or pasteurization processes. Renewable Energy: Supports thermal storage in solar heating systems. Why They Are Preferred: Energy Efficiency: Direct heating minimizes waste. Compact Design: Saves space without compromising performance. Customizable Options: Tailored to specific industrial or domestic needs. Advantages of Immersion Tubular Heater Over Alternatives When compared to other heating solutions, immersion tubular heaters offer distinct advantages: Faster Heating: Direct immersion ensures rapid heat transfer. Durability: High-grade materials extend lifespan, even in corrosive environments. Cost-Effectiveness: Reduced energy consumption lowers operational costs. Safety Features: Equipped with thermal cutoffs and protective coatings to prevent overheating. Maintenance Tips for Long-Term Performance To ensure the longevity and efficiency of your immersion tubular heater, follow these actionable tips: Inspect Regularly: Check for signs of corrosion, scaling, or physical damage on the sheath. Clean Periodically: Prevent scale buildup, especially in hard water applications, to maintain efficiency. Monitor Electrical Connections: Ensure tight and secure connections to avoid power issues. Replace Damaged Components Promptly: A compromised element or sheath can lead to safety hazards. Match Materials to the Medium: Use corrosion-resistant materials for chemicals or saltwater applications. Innovations in Immersion Tubular Heaters The heating industry is constantly evolving. Some recent advancements in immersion tubular heaters include: Smart Temperature Control: Integration with IoT for real-time monitoring and remote adjustments. Energy Optimization: Use of advanced insulation materials to improve energy retention. Custom Designs: Manufacturers now offer more tailored configurations for niche applications. Final Words The immersion tubular heater remains a cornerstone in efficient and reliable heating. By leveraging its principle of direct heat transfer, industries can achieve precise temperature control while saving energy. Regular maintenance and understanding its core functionality can ensure optimal performance for years. Whether you’re looking to heat water in a residential tank or manage a chemical process in an industrial setup, understanding this heater’s principles equips you to make informed decisions.

How to Pick The Best Electric Tubular Heater Supplier

When it comes to selecting an electric tubular heater supplier, your decision can impact everything from energy efficiency to product longevity. A wrong choice might lead to costly replacements, inefficiencies, and disruptions in your operations. With so many options on the market, narrowing down your choice demands a focused and informed approach. This guide will help you pick the best supplier with actionable insights and data-driven tips. Why Your Electric Tubular Heater Supplier Choice Matters The global market for tubular heaters is projected to grow significantly, reaching $1.2 billion by 2030. Industries like manufacturing, healthcare, and food processing depend heavily on these heaters for consistent performance. Poor-quality products or unreliable suppliers can lead to: Increased operational costs. Safety hazards from subpar materials. Unplanned downtime. Partnering with a trusted supplier ensures reliability, quality, and regulatory compliance. Key Factors to Evaluate When assessing suppliers, focus on the following critical elements: 1. Product Quality and Certifications Ensure the supplier offers products that comply with international standards like ISO 9001 and CE. Look for materials like stainless steel or Incoloy, which enhance durability and thermal performance. Check customer reviews or request samples to test the heater’s performance. 2. Experience in the Industry Suppliers with 10+ years of experience typically have refined manufacturing processes and a better understanding of industry needs. Ask questions like: Have they supplied heaters to industries similar to yours? Do they offer customized solutions for specific applications? 3. Energy Efficiency of Their Products With rising energy costs, efficiency is non-negotiable. The best suppliers prioritize energy-efficient designs, reducing electricity consumption by up to 25%. Request data sheets showing energy ratings and performance metrics. How to Verify Electric Tubular Heater Supplier Reliability Relying on claims is risky. Instead, follow these steps to ensure reliability: Check References: Ask for case studies or testimonials from previous clients. Inspect Facilities: If possible, visit the supplier’s manufacturing site to observe quality control measures. Analyze Supply Chain Robustness: Delays in delivery can impact your operations. Verify their logistics capabilities and lead times. Questions to Ask Your Electric Tubular Heater Supplier Make the evaluation process seamless with these questions: Can you provide detailed product specifications and certifications? What’s your standard lead time for bulk orders? How do you ensure consistent product quality across batches? Do you offer after-sales support or warranties? What’s your minimum order quantity, and are discounts available for bulk purchases? Red Flags to Avoid Be cautious of these warning signs: Lack of Transparency: If the supplier hesitates to share certifications or references, it’s a red flag. Unrealistic Pricing: Prices significantly lower than competitors might indicate inferior quality. Inconsistent Communication: Poor customer service early on may signal bigger issues down the line. Final Thoughts Choosing the right electric tubular heater supplier is a decision that extends beyond price. Focus on quality, experience, and reliability. Conduct due diligence, ask the right questions, and prioritize suppliers with a proven track record in your industry. Investing time in this process ensures long-term operational efficiency and cost savings. With the right supplier, your business will have a reliable heating solution tailored to its needs.

Top 3 Industries That Use Cartridge Heater With Thermocouple

A cartridge heater with thermocouple is a critical tool for industries requiring precise temperature control. By integrating a thermocouple, this heater not only generates heat but also provides real-time temperature feedback. This ensures enhanced accuracy, energy efficiency, and improved process reliability. Below, we’ll examine the top industries benefiting from this advanced technology and how it supports their operations. 1. Plastic Manufacturing Plastic manufacturing heavily relies on cartridge heaters with thermocouples for precision heating. From injection molding to extrusion, these heaters are vital for producing high-quality plastic components. Injection Molding: Maintaining accurate temperature profiles in the mold is essential. Any deviation can result in defective products. A cartridge heater with thermocouple ensures the mold temperature remains consistent, leading to fewer errors. Plastic Extrusion: During the extrusion process, plastic materials must reach precise melting points. A built-in thermocouple monitors the temperature in real-time, avoiding overheating or under-heating that could compromise the product’s integrity. Key Benefits for Plastic Manufacturing: Minimized material wastage. Faster production cycles due to consistent heating. Improved product quality with fewer defects. 2. Pharmaceutical and Medical Device Industry Accuracy and cleanliness are paramount in the pharmaceutical and medical device sectors. A cartridge heater with thermocouple helps maintain sterile conditions while ensuring the precision required for sensitive applications. Sterilization Equipment: Cartridge heaters are used in autoclaves and sterilization chambers, ensuring even heating throughout. The thermocouple continuously monitors the temperature, ensuring compliance with strict regulatory standards. Medical Device Manufacturing: Processes like sealing and welding of medical-grade plastics depend on precise temperatures. Thermocouple feedback ensures these processes meet exact specifications, eliminating risks of contamination or faulty seals. Why It’s Essential in This Industry: Supports strict compliance with FDA and ISO standards. Prevents overheating that could damage sensitive materials. Ensures uniform heating critical for sterile environments. 3. Food and Beverage Processing The food and beverage industry also benefits from cartridge heaters with thermocouples, especially for tasks requiring precision and safety. Packaging Machinery: Sealing food packages requires consistent temperatures to avoid weak or over-sealed packaging. Thermocouple-equipped cartridge heaters provide exact temperature feedback, ensuring every seal is reliable. Liquid Heating: Processes like pasteurization or maintaining the warmth of liquid foods depend on temperature stability. With a cartridge heater and thermocouple, the risk of overheating or uneven heat distribution is eliminated. Key Advantages in Food Processing: Maintains consistent quality across batches. Enhances food safety by preventing under-processing. Reduces energy consumption with real-time temperature adjustments. Why Cartridge Heater With Thermocouple Stands Out The integration of a thermocouple into cartridge heaters provides numerous advantages across industries: Real-Time Monitoring: The thermocouple gives immediate feedback, enabling precise adjustments. Energy Efficiency: By avoiding temperature overshoots, these heaters reduce unnecessary energy use. Reliability: They enhance process consistency, leading to higher output quality. Final Thoughts From plastic manufacturing to pharmaceuticals and food processing, the cartridge heater with thermocouple proves invaluable in applications demanding precision and efficiency. Its ability to provide accurate temperature control, coupled with durability, makes it a staple in modern industrial operations. If you’re searching for a heating solution that delivers consistent results, consider this innovative technology.

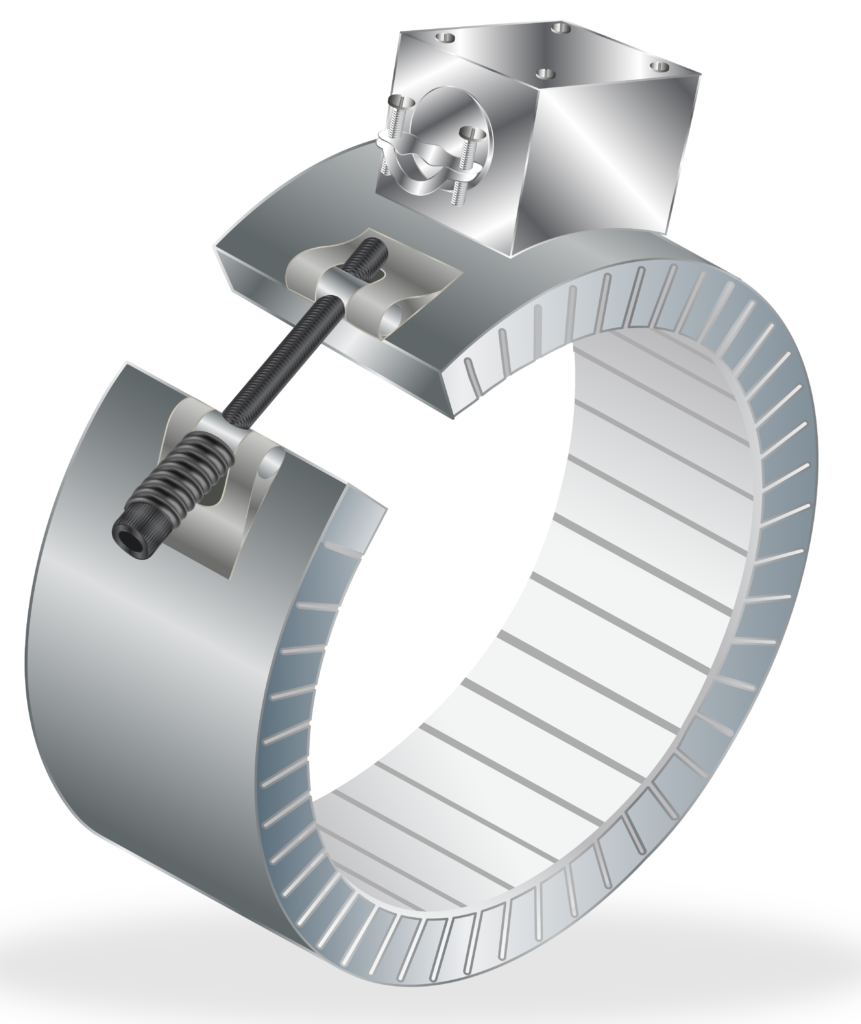

5 Common Applications of a Band Heater

Band heaters are an essential component in industries where consistent heat is crucial for processes and production. Their precision, efficiency, and durability make them indispensable. Used in machinery, manufacturing, and various industrial applications, a band heater plays a critical role in optimizing production. In this article, we’ll see five common applications where band heaters are most effective and beneficial. 1. Plastic Injection Molding Plastic injection molding is a complex process requiring exact temperature control. In this application, band heaters are essential for heating the nozzles and barrels that melt plastic pellets before they’re injected into molds. Here’s why band heaters are ideal for this application: Precision Control: Band heaters allow for precise heat application, keeping the plastic at the right temperature for optimal flow. Energy Efficiency: With their direct contact heating, band heaters reduce energy wastage, cutting down on operational costs. Durability: Many band heaters are built to withstand long operational hours, reducing downtime and boosting productivity. 2. Food Processing Equipment Band heaters play a significant role in food processing, particularly in machines that rely on heated cylinders or pipes. From pasteurization to canning and drying processes, band heaters provide consistent heat, ensuring that food products are safe and of high quality. Even Heating: Band heaters apply uniform heat to prevent hotspots, which is critical for food quality and safety. Safety Compliance: Many band heaters are designed with materials and coatings that comply with food-grade safety standards, maintaining cleanliness and preventing contamination. Customizable Temperature: Adjustable temperature controls allow for flexibility across various stages of food processing, from heating to maintaining temperatures. 3. Pharmaceutical Manufacturing In pharmaceutical production, accuracy and consistency are paramount. Band heaters are commonly used in reactors, dryers, and other equipment that require constant heat to process active ingredients, ensuring product stability and quality. Stable Heating for Sensitive Ingredients: Band heaters maintain a stable environment, crucial for sensitive chemical reactions. Enhanced Safety: Pharmaceutical applications demand heaters that minimize the risk of overheating. Band heaters with protective controls help meet this need. Compatibility with Stainless Steel: Many band heaters are compatible with stainless steel reactors, which are standard in pharmaceutical production for their resistance to corrosion. 4. Packaging Machinery Band heaters are also frequently found in packaging machinery, where they heat and seal materials such as plastic, foil, and laminates. Reliable and consistent heating is essential to produce secure seals that protect product quality during transit and storage. High-Quality Seals: Band heaters enable precise temperature control to produce tight, durable seals. Reduced Downtime: Packaging operations run continuously, and band heaters with high thermal efficiency minimize energy consumption and maintenance requirements. Adjustable Heating for Different Materials: Band heaters allow easy adjustments to accommodate various packaging materials, making them versatile for packaging multiple types of goods. 5. Diesel Engine Preheating A band heater is often used in the automotive industry, especially in preheating diesel engines in colder climates. Preheating diesel engines ensures a smoother start, prevents engine damage, and reduces emissions from incomplete combustion. Quick Start in Cold Weather: Band heaters make diesel engines easier to start, even in freezing conditions. Reduced Wear on Engine Components: Preheating reduces stress on engine components, extending engine life. Improved Fuel Efficiency: By optimizing combustion, band heaters help improve fuel efficiency and reduce harmful emissions. Final Thoughts The band heater remains a fundamental solution in industries demanding consistent and efficient heating. Whether it’s for plastic injection molding or ensuring safe food processing, the flexibility, reliability, and efficiency of band heaters make them an excellent choice across various applications.