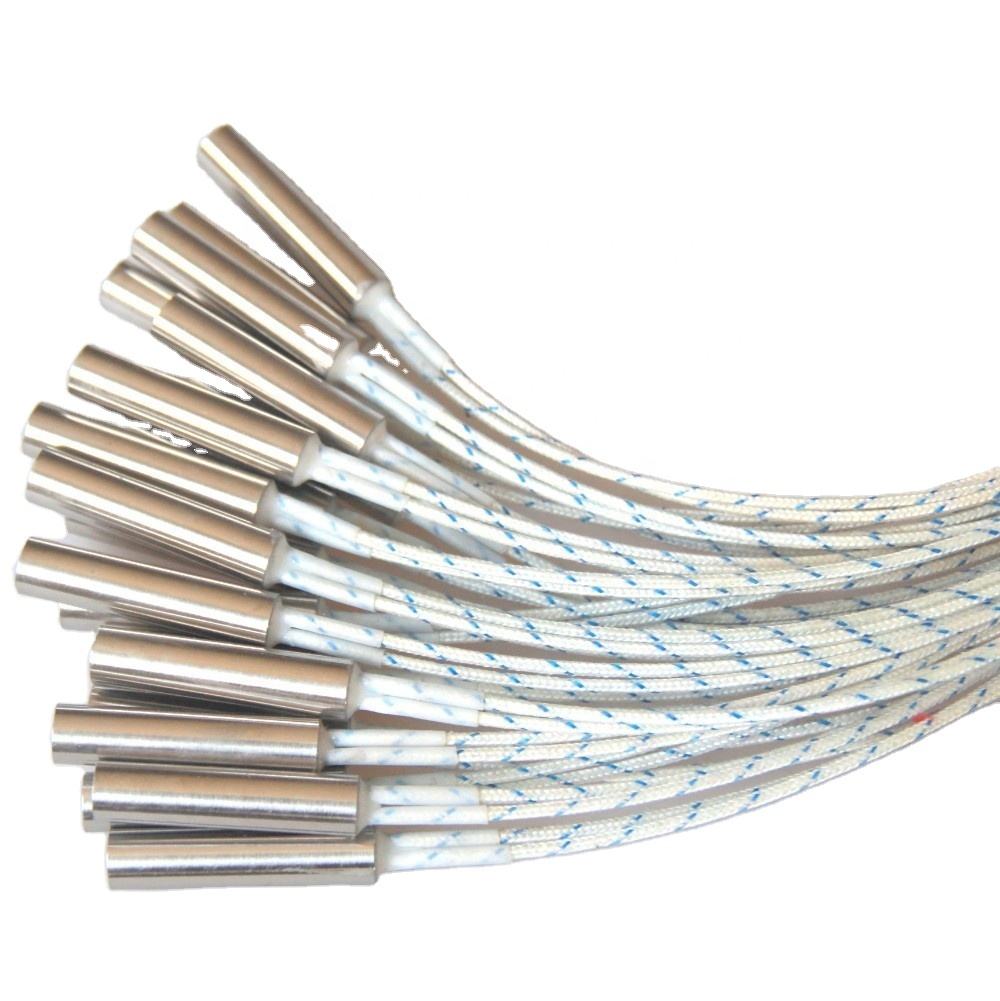

What Material is Used for Thread Cartridge Heaters

Thread cartridge heaters are essential in industries requiring precise and efficient heating. These heaters are cylindrical devices designed to transfer heat effectively. But have you ever wondered what materials make them so reliable and durable? This blog will explore the key materials used in thread cartridge heaters, why they are chosen, and how they enhance performance. Understanding Thread Cartridge Heaters Thread cartridge heaters are compact, high-temperature heating elements. They are often used in molds, dies, medical devices, and packaging equipment. The materials used in their construction play a significant role in ensuring their functionality. Each component is carefully designed to withstand harsh conditions, maintain efficiency, and ensure safety. Core Materials in Thread Cartridge Heaters Several materials are used to manufacture these heaters. Each serves a unique purpose and contributes to the heater’s durability and performance. 1. Sheath Material The sheath is the outermost layer of the heater. It protects internal components and ensures heat transfer. Common materials include: Stainless Steel: Known for corrosion resistance, it works well in high-temperature and moisture-prone environments. Incoloy: A nickel-based alloy, it offers excellent resistance to oxidation and scaling in extreme heat. Copper: Often used when rapid heat transfer is required. 2. Heating Element The heating element inside the cartridge generates heat. Typical materials include: Nickel-Chromium (Ni-Cr) Wire: Offers high electrical resistance and can withstand high temperatures. Kanthal Wire: Made from iron-chromium-aluminum, it provides exceptional longevity at elevated temperatures. 3. Insulation Material Insulation ensures the heat stays concentrated within the heater. Common materials are: Magnesium Oxide (MgO): This powder or compacted form has high thermal conductivity and electrical insulation properties. Ceramic Insulation: Used for extra durability and resistance to electrical breakdown. 4. Lead Wire Materials Lead wires connect the heater to the power source. They must withstand both heat and mechanical stress. Silicone-Insulated Wires: Ideal for flexibility and temperature resistance. Fiberglass-Insulated Wires: Used in high-temperature applications due to their excellent thermal resistance. Why These Materials Are Chosen Each material is selected based on specific properties that enhance the cartridge heater’s performance: High Thermal Conductivity: Ensures efficient heat transfer to the target application. Corrosion Resistance: Protects against harsh environments, extending heater life. Electrical Insulation: Prevents short circuits and ensures user safety. Mechanical Strength: Withstands vibrations and physical stress without damage. Key Benefits of Using the Right Materials Using the correct materials in threaded cartridge heaters ensures several advantages: Enhanced Efficiency: Proper materials ensure minimal heat loss and faster heating. Extended Lifespan: Durable materials resist wear and tear, even under tough conditions. Improved Safety: High-quality insulation materials prevent electrical hazards. Applications of Thread Cartridge Heaters Thread cartridge heaters are widely used across industries. Here are some common applications: Plastic Injection Molding: Heating molds to specific temperatures. Medical Equipment: Precise heating for sterilization or fluid control. Food Processing: Maintaining temperatures in packaging and sealing machines. Automotive Industry: Supporting heating systems for dies and molds. Wrap Up Thread cartridge heaters rely on carefully selected materials to deliver consistent performance in demanding environments. The combination of stainless steel sheaths, nickel-chromium elements, magnesium oxide insulation, and durable lead wires ensures these heaters are efficient, durable, and safe. When choosing or maintaining a thread cartridge heater, understanding the materials used can help you make informed decisions for your application.

What is Cartridge Heater With Thermocouple – A Short Guide

Cartridge heaters with thermocouples are essential tools in many industries. They combine heating elements with temperature sensors for precision. These heaters are designed to deliver localized heat and maintain accurate temperature control in various applications. If you’re working in manufacturing, engineering, or electronics, understanding these heaters can make a big difference in achieving efficient operations. This short guide will explain what they are, how they work, and where they are commonly used. What is a Cartridge Heater With Thermocouple? A cartridge heater is a cylindrical heating element. It generates heat by passing electricity through a resistive wire inside a metal casing. The addition of a thermocouple allows real-time temperature monitoring. The thermocouple is a built-in sensor that measures the heater’s temperature. This feature ensures consistent and controlled heating in critical processes. Cartridge heaters are available in various sizes, wattages, and materials. They are widely used in processes where precision heating is essential, such as plastic molding, food equipment, and medical devices. How Does a Cartridge Heater With Thermocouple Work? These heaters work on the principle of resistance heating. The resistive wire heats up when an electric current flows through it. The heat is transferred to the surrounding area via the metal sheath. The thermocouple plays a key role in temperature control. It measures the temperature at a specific point and sends the data to a controller. If the temperature exceeds or drops below the set range, the controller adjusts the power supply to maintain stability. Key Components of a Cartridge Heater With Thermocouple: Heating Element: Usually made of nickel-chromium (NiCr) wire for high efficiency. Metal Sheath: Protects the internal components and ensures efficient heat transfer. Common materials include stainless steel and Incoloy. Thermocouple: Often a Type J or K thermocouple is integrated for accurate temperature sensing. Insulation: High-purity magnesium oxide (MgO) is used for electrical insulation and heat conduction. Advantages of Cartridge Heaters With Thermocouples These heaters offer several benefits that make them a popular choice in industries: Precise Temperature Control: Thermocouples enable accurate and real-time temperature monitoring. High Efficiency: They quickly reach desired temperatures, reducing energy consumption. Durability: Built with robust materials to withstand high temperatures and harsh environments. Versatility: Suitable for various applications, from industrial to commercial use. Common Applications of Cartridge Heaters With Thermocouples Cartridge heaters are used in multiple industries. Here’s where they are commonly found: Plastic and Rubber Molding: For heating molds and dies evenly. Packaging Machines: Used in sealing equipment to maintain consistent heat. Medical Devices: Found in diagnostic and sterilization equipment. Food Equipment: Used in cooking, baking, and warming appliances. 3D Printing: Helps in heating nozzles and maintaining stable temperatures. Choosing the Right Cartridge Heater With Thermocouple Selecting the right heater involves several factors. These include size, watt density, and operating temperature. Here’s a quick checklist to help you choose: Size and Fit: Ensure the heater matches the dimensions of the application. Wattage: Higher watt density is needed for faster heating in demanding applications. Temperature Range: Consider the operating environment to choose a suitable material. Type of Thermocouple: Type J and K are the most common for their reliability and range. Maintenance Tips for Cartridge Heaters With Thermocouples Proper care ensures a long service life. Here are some tips: Inspect Regularly: Check for signs of wear or damage. Clean Periodically: Remove dirt or residue to avoid overheating. Ensure Proper Fit: Loose heaters may cause uneven heating or failure. Monitor Thermocouple: Replace if the sensor becomes inaccurate. Final Thoughts Cartridge heaters with thermocouples are reliable and efficient heating tools for precision applications. Their ability to provide controlled heat makes them indispensable in various industries. By understanding how they work and selecting the right model, you can achieve better performance and longer service life. Whether it’s plastic molding or food processing, these heaters are a smart solution for your heating needs.

5 Best Ways to Do Quality 3D Heat Printing

3D printing has changed the way we create and design. To get the best results, you need a reliable setup. One key part is the heater, and that’s why finding the right 3D printer heater manufacturers is so important. A good heater ensures consistent heat, leading to better prints. In this post, we’ll explore five ways to improve your 3D heat printing quality. 1. Choose the Right 3D Printer Heater The heater is the heart of your 3D printer. It controls the temperature, which affects how the material melts and bonds. Picking the right heater ensures smooth and strong prints. Tips for choosing the best heater: Compatibility: Make sure the heater matches your printer model. Power rating: Higher wattage can heat up faster and handle tougher materials. Material: Heaters made with high-grade metals last longer and perform better. Reputation of manufacturers: Research trusted 3D printer heater manufacturers to ensure quality. Heater Type Best For Key Features Ceramic Heaters Consistent heat distribution Durable and stable temperature Cartridge Heaters High heat for advanced materials Compact and efficient design 2. Use High-Quality Filament The filament directly impacts print quality. Cheap materials often lead to uneven melting and weak prints. Checklist for high-quality filament: Consistent diameter for even extrusion. Check for moisture resistance to avoid bubbles. Choose filaments rated for your heater’s temperature range. Popular options include PLA, ABS, and PETG for standard projects, while nylon and carbon-fiber blends work for tougher prints. 3. Calibrate the Printer Properly Calibration ensures that every part of your printer works in harmony. Incorrect settings can ruin your prints. Key calibration steps: Level the print bed: Use a piece of paper to set the gap between the nozzle and the bed. Adjust the nozzle temperature: Follow the filament’s recommended temperature. Check the flow rate: Make sure the material extrudes at the right speed. Test print a calibration model: This will highlight any issues in your settings. Pro tip: Keep a log of your calibration settings for future reference. 4. Control the Print Environment External factors can affect heat distribution and print quality. A stable environment ensures consistent results. Tips to control your workspace: Keep the room free from drafts to avoid uneven cooling. Use an enclosure to maintain a steady temperature. Avoid humid conditions that can affect filament properties. 5. Perform Regular Maintenance Regular maintenance keeps your printer in top condition. A well-maintained machine delivers better prints. Maintenance checklist: Clean the nozzle to prevent clogs. Inspect wires and connectors for wear. Check the heater’s performance regularly to ensure proper function. Lubricate moving parts for smooth operation. Final Thoughts Quality 3D heat printing requires attention to detail and the right equipment. Start by choosing the best 3D printer heater manufacturers to ensure reliability. Pair this with quality filaments, proper calibration, and a stable environment to achieve excellent prints. With regular maintenance, you can ensure long-term success. Stick to these steps, and your prints will turn out smooth, precise, and durable.

How to Find the Best CO2 Heater Element Manufacturer Online

Finding the right CO2 heater element manufacturer is a crucial step for businesses and individuals needing reliable heating solutions. With numerous options available online, the challenge lies in identifying a trusted provider that meets your requirements. CO2 heater elements are widely used in industries like agriculture, medical devices, and manufacturing. Choosing the wrong manufacturer can lead to inefficient systems and increased costs. This guide will help you discover the best online manufacturer while ensuring top-notch quality and service. Why CO2 Heater Elements Are Important CO2 heater elements are vital in maintaining consistent temperatures in equipment that uses carbon dioxide. These heaters enhance performance and ensure energy efficiency. Here’s why they’re critical: Precision Heating: Ensures consistent thermal output for sensitive applications. Energy Efficiency: Reduces energy consumption by delivering targeted heat. Durability: High-quality materials ensure long-lasting performance in demanding environments. Safety: Minimizes risks of overheating or equipment failure. Given their importance, sourcing them from a trusted manufacturer ensures peace of mind and long-term benefits. Steps to Identify a Reliable CO2 Heater Element Manufacturer Online Search for Reputable Companies Begin with a focused online search for manufacturers specializing in CO2 heater elements. Look for high-ranking websites and industry-specific directories. Use search terms like “certified CO2 heater element manufacturers.” Check if the website looks professional and provides detailed product information. Evaluate Product Quality Not all CO2 heater elements are created equal. Look for the following indicators of high-quality products: Material Details: Manufacturers should use corrosion-resistant and heat-tolerant materials like stainless steel. Certifications: Ensure the manufacturer adheres to ISO standards or industry-specific certifications. Customer Reviews: Positive feedback often reflects consistent product quality. Check Manufacturing Capabilities A good manufacturer offers advanced production facilities and flexible customization options. Important factors to assess include: Production Volume: Can they meet your demand scale? Customization: Do they offer size or design modifications for specific applications? Lead Time: How quickly can they deliver your order? Compare Pricing and Warranty Options Price is always a factor, but cheaper doesn’t always mean better. Check for competitive pricing without compromising quality. Request Quotes: Compare prices from multiple manufacturers. Warranty: Choose manufacturers offering solid warranties on their heater elements. Review Customer Support Excellent customer service is an essential marker of a reliable company. Look for manufacturers offering: Technical Assistance: Pre- and post-sale support. Detailed Guides: Product manuals or troubleshooting guides. Responsive Communication: Quick responses to emails or inquiries. Key Features to Look for in a CO2 Heater Element To ensure you’re purchasing the right heater element, consider the following features: Questions to Ask the Manufacturer Asking the right questions helps verify the manufacturer’s credibility and ensures a smoother purchasing experience: What materials are used in your CO2 heater elements? Can you provide a list of certifications or quality standards? Do you offer custom designs for unique applications? What is the typical delivery time for bulk orders? What support do you provide after the purchase? Top Benefits of Choosing the Right Manufacturer When you select a reliable CO2 heater element manufacturer, you enjoy several benefits: Consistent Quality: High-performance products with fewer breakdowns. Reduced Costs: Energy-efficient solutions lower operational expenses. Expert Support: Reliable technical assistance for installation and maintenance. Timely Delivery: Keeps your operations running smoothly. Final Thoughts Finding the best CO2 heater element manufacturer online requires research, attention to detail, and a focus on quality. By following these steps, you can identify a trusted provider offering durable, efficient, and high-performing heater elements. Always prioritize companies with excellent customer reviews, transparent policies, and a commitment to quality standards. A smart choice today ensures long-term benefits for your operations.

How to Find Cartridge Heater Suppliers Online

Cartridge heaters are essential for industries requiring precise temperature control. Whether for plastic molding, food processing, or laboratory equipment, finding reliable cartridge heater suppliers online is crucial. Choosing the right supplier impacts product quality, operational efficiency, and long-term cost savings. This guide will help you discover the best suppliers without feeling overwhelmed. Why Choosing the Right Supplier Matters The right supplier ensures you get high-quality cartridge heaters tailored to your needs. A reliable supplier offers: Durable products that meet industry standards. Customization options for specific applications. Technical support to address your challenges. Timely delivery to avoid production delays. Skipping these factors can lead to costly downtime and substandard performance. Let’s explore how to find the perfect supplier online. 1. Start with Online Research The internet is your best tool for finding reliable suppliers. Follow these steps: Use Search Engines Wisely Search for “cartridge heater suppliers near me” or “top-rated cartridge heater suppliers online.” Include specific terms like custom cartridge heaters or industrial-grade cartridge heaters. Look for suppliers ranking on the first page, as these are often the most trusted. Check Supplier Websites When browsing supplier websites: Ensure the company specializes in cartridge heaters. Look for detailed product descriptions with specifications. Verify if they mention certifications like ISO or CE compliance. Explore Online Marketplaces Platforms like: Alibaba ThomasNet Global Sources Host numerous cartridge heater suppliers. Compare ratings, reviews, and pricing before making contact. 2. Assess Supplier Credibility A supplier’s reputation speaks volumes about their reliability. Here’s how to check: Read Online Reviews Use platforms like Google Reviews or Trustpilot for unbiased opinions. Pay attention to common complaints, such as delivery delays or product defects. Ask for References Request customer references to gauge satisfaction levels. Contact their clients to ask about service reliability and product quality. Verify Certifications Suppliers with proper certifications ensure safety and performance standards. Common certifications include: 3. Evaluate Product Range and Features A diverse product catalog indicates a supplier’s capability to handle various needs. When reviewing options, consider: Wattage and voltage ranges. Materials like stainless steel or Incoloy for durability. Customizable sizes for specific applications. Look for Special Features Rapid heat-up time. Energy efficiency. Uniform temperature distribution. Compare these features across multiple suppliers to find the best match. 4. Compare Pricing and Lead Times Price and delivery time directly impact your project timelines and budget. Request Quotes Contact multiple suppliers to get detailed quotes. Look for: Pricing per unit for bulk orders. Discounts or special offers for repeat customers. Ask About Delivery Times Confirm lead times to ensure the supplier meets your schedule. Check if they offer expedited shipping options. Factor in Hidden Costs Customs or import fees for international orders. Shipping charges for small quantities. 5. Customer Support and After-Sales Service Customer service is critical for long-term partnerships. Prioritize suppliers offering: 24/7 support channels like live chat or phone assistance. Installation guides for quick setup. Warranty policies covering repairs or replacements. 6. Test the Supplier with Small Orders Before placing bulk orders, test the supplier’s reliability: Order a small batch to assess product quality. Monitor delivery times and packaging. Evaluate their responsiveness to issues or questions. Red Flags to Avoid Stay cautious if you notice: Vague product descriptions or missing technical details. No certifications or unclear warranty policies. Poor communication or delayed responses. Final Thoughts Finding the best cartridge heater suppliers online requires careful research and evaluation. From product quality to customer support, each factor plays a role in your decision. By following this guide, you can confidently select a supplier that meets your needs and ensures reliable performance. Remember, a dependable supplier like Cheri Heater is not just a vendor but a long-term partner in your success.