Flexible Heater Manufacturer: Powering Precision and Innovation

In today’s fast‑paced industrial world, heating solutions must be versatile, efficient, and reliable. Flexible heaters have emerged as a game‑changing technology, offering manufacturers across industries the ability to achieve precise temperature control in complex applications. At Cheri Heater, we specialize in designing and manufacturing flexible heaters that meet the highest standards of performance and durability. What Is a Flexible Heater? A flexible heater is a thin, bendable heating element designed to deliver consistent heat across irregular surfaces or confined spaces. Unlike traditional rigid heaters, flexible heaters can be customized to fit unique shapes, making them ideal for applications where precision and adaptability are critical. Advantages of Flexible Heaters Versatility: Flexible heaters can be applied to flat, curved, or irregular surfaces, making them suitable for diverse industries. Precision Heating: They provide uniform temperature distribution, reducing hot spots and ensuring consistent performance. Energy Efficiency: By delivering heat exactly where it’s needed, flexible heaters minimize energy waste. Durability: Built with advanced materials, they withstand demanding environments, including moisture, vibration, and chemical exposure. Customization: Flexible heaters can be tailored in size, shape, and wattage to meet specific application requirements. Applications Across Industries Flexible heaters are widely used in industries where precision and reliability are non‑negotiable: Medical Equipment: Ensuring accurate heating in diagnostic devices, surgical tools, and patient care systems. Electronics: Preventing condensation and maintaining optimal operating temperatures in sensitive components. Automotive: Supporting defrosting, battery warming, and other critical heating functions. Aerospace: Providing lightweight, efficient heating solutions for aircraft systems. Food Processing: Maintaining consistent temperatures in packaging and production equipment. Cheri Heater: Your Trusted Flexible Heater Manufacturer At Cheri Heater, we combine innovation with craftsmanship to deliver flexible heaters that exceed expectations. Our manufacturing process emphasizes: Advanced Materials: We use high‑quality silicone rubber, polyimide, and other durable substrates to ensure long‑lasting performance. Custom Engineering: Every heater is designed to meet the unique needs of our clients, from size and shape to watt density. Quality Assurance: Rigorous testing guarantees that each product performs reliably under real‑world conditions. Global Reach: Serving industries worldwide, Cheri Heater is recognized as a trusted partner in heating technology. Why Choose Cheri Heater? Expertise: Years of experience in heater manufacturing. Innovation: Cutting‑edge designs tailored to modern industry demands. Reliability: Products engineered for consistent performance. Customer Support: Dedicated service to help clients optimize their heating solutions. Looking Ahead As industries evolve, the demand for efficient, adaptable heating solutions will continue to grow. Flexible heaters are at the forefront of this transformation, enabling manufacturers to achieve greater precision, sustainability, and productivity. At Cheri Heater, we are proud to lead the way as a flexible heater manufacturer, delivering solutions that empower businesses to innovate and succeed.

The Essential Role of Hot Runner Heaters in Modern Manufacturing

In the world of plastic injection molding, efficiency, precision, and consistency are everything. Manufacturers across industries from automotive to consumer goods rely on advanced heating solutions to ensure their molds produce high‑quality parts with minimal waste. At the heart of this process lies the hot runner heater, a critical component that powers innovation and productivity. What Is a Hot Runner Heater? A hot runner heater is a specialized heating element designed to maintain the precise temperature of molten plastic as it flows through the hot runner system of an injection mold. Unlike cold runner systems, which allow plastic to cool and solidify in channels that must later be trimmed away, hot runner systems keep the material at the ideal temperature until it reaches the cavity. This eliminates excess waste, reduces cycle times, and ensures consistent part quality. Why Hot Runner Heaters Matter Precision Temperature Control: Even a small fluctuation in temperature can affect the flow of plastic, leading to defects such as short shots, flash, or warping. Hot runner heaters provide stable, uniform heating to avoid these issues. Energy Efficiency: By reducing material waste and optimizing cycle times, hot runner systems save energy and lower overall production costs. Improved Product Quality: Consistent heating ensures that every molded part meets exact specifications, which is vital for industries like medical devices and electronics where tolerances are tight. Reduced Maintenance: Modern hot runner heaters are designed for durability, minimizing downtime and extending the lifespan of molds. Applications Across Industries Hot runner heaters are indispensable in sectors where precision and speed are non‑negotiable: Automotive: From dashboards to intricate connectors, hot runner systems help produce complex parts with high repeatability. Medical: Syringes, diagnostic components, and surgical instruments require flawless molding, achievable only with precise heating. Consumer Goods: Everyday items like packaging, toys, and household products benefit from the efficiency of hot runner technology. Electronics: Small, detailed components demand uniform heating to avoid defects that could compromise performance. Cheri Heater: Your Partner in Heating Solutions At Cheri Heater, we specialize in designing and delivering advanced heating solutions tailored to the needs of modern manufacturers. Our hot runner heaters are engineered with cutting‑edge technology to provide: Uniform Heat Distribution: Ensuring consistent flow and reducing defects. Customizable Designs: Adaptable to different mold configurations and industry requirements. Durability and Reliability: Built to withstand demanding production environments. Technical Support: Our team works closely with clients to optimize performance and troubleshoot challenges. Looking Ahead As industries continue to demand faster production cycles, higher precision, and sustainable practices, hot runner heaters will remain a cornerstone of innovation. By investing in advanced heating solutions, manufacturers not only improve their bottom line but also contribute to a greener future by reducing waste and energy consumption. At Cheri Heater, we are proud to support this progress by providing reliable, efficient, and customizable hot runner heaters that empower businesses to achieve excellence.

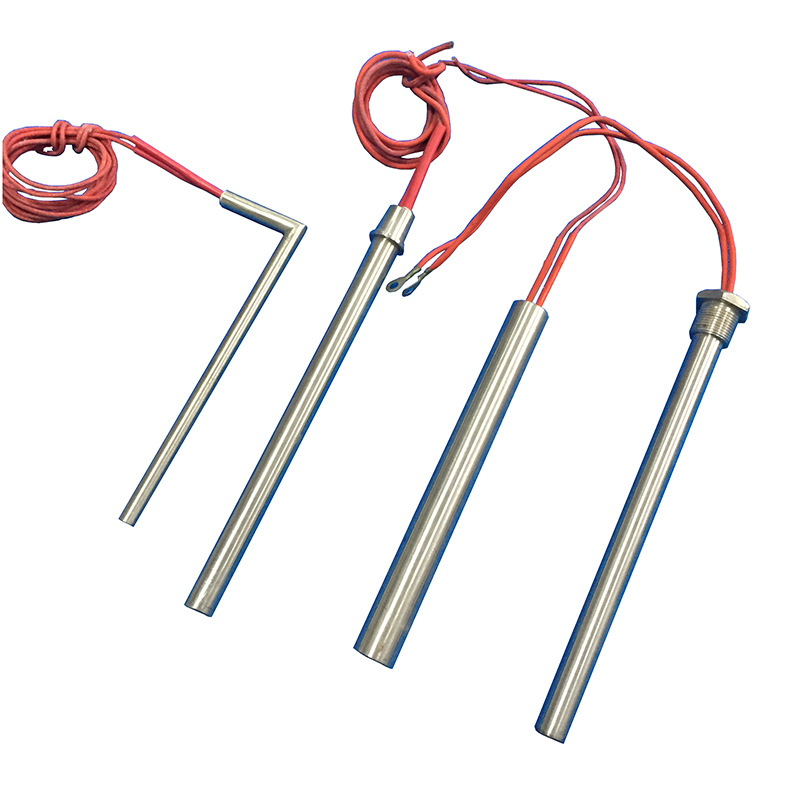

Cartridge Heater Manufacturer A Complete Guide to Choosing the Right Partner

Let’s start simple. If your machine needs precise, reliable heat in a compact space, chances are it relies on a cartridge heater. These small but powerful heating elements are the unsung heroes inside molds, dies, packaging machines, and medical devices. Behind every dependable heater is a skilled cartridge heater manufacturer. And choosing the right one? That can mean the difference between smooth production and constant downtime. So, how do cartridge heaters really work, what should you expect from a manufacturer, and how do you choose the right partner? Let’s break it all down. What Does a Cartridge Heater Manufacturer Do? A cartridge heater manufacturer doesn’t just make metal tubes with wires inside. They design, engineer, test, and customize heating solutions for very specific industrial needs. From selecting the right sheath material to calculating watt density and insulation, manufacturers ensure each heater delivers: Accurate temperature control Long service life Safe electrical performance Consistent heating In other words, they don’t sell products. They deliver reliability. Why Cartridge Heaters Matter in Modern Industry Imagine an injection molding machine that can’t maintain stable temperature. Or a sealing machine that overheats and damages packaging. Sounds expensive, right? Cartridge heaters provide: Fast heat-up times Uniform heat distribution Compact installation Precise temperature control That’s why industries trust them in high-performance and high-precision applications. How Cartridge Heaters Work At their core, cartridge heaters convert electrical energy into heat through resistance wire. Here’s the simple process: Electricity flows through resistance wire The wire heats up due to electrical resistance Heat transfers through insulation The metal sheath delivers heat to the application It’s simple physics, perfected by smart engineering. Core Components of a Cartridge Heater A high-quality cartridge heater typically includes: Resistance wire for heat generation Magnesium oxide insulation for electrical safety and thermal transfer Metal sheath for protection and heat delivery Lead wires or terminals for electrical connection Each component plays a critical role in performance and lifespan. Types of Cartridge Heaters Not all cartridge heaters are created equal. Manufacturers usually offer: Low-density cartridge heaters Medium-density cartridge heaters High-density cartridge heaters Swaged cartridge heaters Square or rectangular heaters for special slots Choosing the right type depends on temperature, space, and watt density. How to Choose the Right Cartridge Heater Manufacturer Now we’re getting to the important part. Not all manufacturers offer the same quality or service. Quality Standards and Certifications Always check for: ISO certifications Compliance with international electrical standards Documented quality systems Certifications show discipline. And discipline shows reliability. Customization Capabilities Standard heaters don’t always fit. A good manufacturer should offer: Custom diameters and lengths Special voltages and watt densities Unique lead configurations If they can’t customize, they can’t optimize. Engineering Support and Design Services Great manufacturers don’t just take orders. They ask questions. They help you select: Proper watt density Correct sheath material Right insulation for your environment That engineering support saves you from expensive mistakes. Production Capacity and Lead Times Ask yourself: Can they handle large volumes? Can they deliver on time? Do they keep stock for urgent needs? Delays in heaters often mean delays in production. Materials and Technology Used in Cartridge Heaters Materials matter more than most people realize. Sheath Materials Explained Common sheath materials include: Stainless steel Incoloy Copper Each material handles heat, corrosion, and pressure differently. Resistance Wire and Insulation High-quality resistance wire ensures: Stable heating Long life Minimal drift over time Magnesium oxide insulation provides both electrical safety and excellent thermal transfer. Advanced Manufacturing Techniques Modern manufacturers use: Precision swaging Automated winding Computer-controlled testing Technology improves consistency and reduces defects. Customization Options Offered by Manufacturers Customization is where great manufacturers shine. Voltage and Watt Density Options You can choose: Low watt density for long life High watt density for fast heating Special voltages for unique systems This flexibility improves both performance and durability. Diameter and Length Variations Manufacturers can produce heaters: From very thin to thick diameters Short or extra-long lengths Straight or bent designs This allows perfect fitting into any application. Lead Wire and Termination Styles Options include: Fiberglass leads Stainless steel braid Screw terminals Ceramic caps Each option suits a different environment. Quality Control and Testing Processes This is where good manufacturers separate themselves from average ones. Electrical Testing Before shipment, heaters are tested for: Insulation resistance Continuity Voltage integrity This prevents dangerous electrical failures. Thermal Performance Testing Manufacturers check: Heat output accuracy Uniform temperature distribution Stability under load Heat that drifts is heat you can’t trust. Long-Term Reliability Checks Some manufacturers perform: Life cycle testing High-temperature endurance tests Vibration testing Because real-world conditions are harsh. Global vs Local Cartridge Heater Manufacturers Should you buy local or global? There’s no single right answer. Advantages of Local Manufacturing Local suppliers offer: Faster delivery Easier communication Better after-sales support They’re often ideal for urgent or customized orders. Benefits of Global Suppliers Global manufacturers may provide: Lower costs Large-scale production Wide product catalogs They’re useful for high-volume standard heaters. Cost Factors in Cartridge Heater Manufacturing Why do prices vary so much? Material Costs Premium materials increase: Durability Temperature limits Corrosion resistance Cheap materials reduce life expectancy. Design Complexity Custom designs require: Engineering time Special tooling Extra testing That adds to cost, but also to performance. Order Volume Impact Large orders often mean: Lower unit prices Better delivery priority Long-term supply agreements Volume matters in pricing. Future Trends in Cartridge Heater Manufacturing The industry isn’t standing still. Energy-Efficient Designs Manufacturers are developing: Lower power loss designs Better insulation Optimized watt density Efficiency saves energy and money. Smart Heating Solutions Some heaters now include: Built-in sensors Smart temperature monitoring Predictive maintenance features Welcome to the era of intelligent heating. Sustainable Manufacturing Eco-friendly practices include: Reduced waste Recyclable materials Energy-efficient production Sustainability is becoming a competitive advantage. Conclusion Choosing the right cartridge heater manufacturer isn’t just a purchasing decision. It’s a strategic one. The right partner delivers: Reliable performance Custom-engineered solutions Long product life Strong technical support In a world where downtime costs money, quality heating is an investment, not an expense. Choose wisely,

High Temperature Cable the Complete 2025 Expert Guide

Let’s face it heat is one of the biggest enemies of electrical systems. Whether it’s a blazing factory floor, a roaring furnace, or an industrial oven operating around the clock, regular cables just can’t survive in these harsh environments. That’s exactly where high temperature cables step in like unsung heroes. What Is a High Temperature Cable? A high temperature cable is a specially engineered electrical wire designed to operate safely and reliably under extreme heat. Unlike regular wires that start breaking down at 80–105°C, these cables can handle temperatures ranging from 150°C to over 1000°C, depending on materials and design. Think of them as heat-proof armor for your electrical systems. Why High Temperature Resistance Matters When ordinary cables face excessive heat, their insulation melts, cracks, or becomes brittle leading to short circuits, power loss, fires, and expensive downtime. High temperature cables prevent all that chaos. They maintain electrical stability even when the heat is relentless, ensuring safety and uninterrupted performance. How High Temperature Cables Work At first glance, a cable might seem simple, but inside, it’s a carefully engineered system designed to survive extreme conditions. Core Electrical Structure The heart of any cable is its conductor, usually copper or nickel-plated copper. This ensures smooth electrical flow even under continuous heat. High temperature conductors are designed to minimize resistance fluctuations due to heat expansion. Insulation vs Jacket Key Differences Insulation protects the conductor from short circuits. Outer jacket shields the cable from mechanical damage, chemicals, oils, and environmental hazards. In high temperature cables, both layers are made from materials that resist thermal breakdown. Heat Transfer and Electrical Stability These cables slow down heat transfer toward the conductor and prevent electrical leakage. This balance keeps voltage stable even in scorching environments kind of like thermal insulation for your electricity. Types of High Temperature Cables Different industries demand different heat resistance levels. Here are the most popular types you’ll encounter: Silicone Rubber Cables These cables handle temperatures up to 200–250°C. They’re extremely flexible and ideal for dynamic environments like robotics, conveyor systems, and heating appliances. PTFE (Teflon) High Temperature Cables PTFE cables can withstand up to 260°C continuously and even higher peaks. They offer outstanding chemical resistance and are commonly used in chemical plants, aerospace, and medical equipment. Fiberglass Insulated Cables Designed for 400–500°C, fiberglass cables are often found in furnaces, kilns, and steel plants. They resist flames but require protective coatings for moisture resistance. Mica Insulated Cables For extreme temperatures reaching 1000°C, mica-insulated cables dominate. These are used in fire survival circuits, emergency power systems, and heavy industries. Materials Used in High Temperature Cables Materials determine everything from heat resistance to flexibility and lifespan. Conductors Bare copper Tin-plated copper Nickel-coated copper Nickel conductors are preferred for ultra-high heat environments. Insulation Materials Silicone rubber PTFE (Teflon) Fiberglass Mica tape Ceramic compounds Each insulation type offers a unique balance between heat resistance and flexibility. Outer Sheathing Outer jackets protect against: Abrasion Oil Chemicals UV radiation Mechanical stress Common sheath materials include fluoropolymers, braided fiberglass, and silicone compounds. Temperature Ratings Explained Not all heat resistance is created equal. Low vs Medium vs Extreme Heat Levels 150–200°C: Home appliances and light industrial use 250–400°C: Heavy manufacturing equipment 500–1000°C: Steel plants, furnaces, emergency systems Continuous vs Peak Temperature Ratings Continuous rating: Safe long-term operating temperature Peak rating: Maximum heat the cable can tolerate briefly Ignoring these limits can shorten cable life drastically. Industrial Applications of High Temperature Cables These cables are everywhere high heat exists. Manufacturing & Automation Robotic arms, molding machines, and automated systems constantly face heat from motors and friction. High temperature cables keep the power flowing without failure. Power Plants From boilers to turbines, thermal power plants depend heavily on heat-resistant wiring to avoid catastrophic breakdowns. Steel & Foundry Industry Few environments are harsher than molten metal operations. High temperature cables ensure uninterrupted control and safety circuits. Plastic & Rubber Processing Extruders, injection molding machines, and hot runner systems rely on precise temperature control made possible by heat-resistant cables. High Temperature Cables in Household & Commercial Use Not everything high-temp is industrial. These cables also quietly power your daily life. Ovens and Heating Appliances Electric ovens, geysers, heaters, and stoves require wiring that won’t burn under constant heat exposure. HVAC Systems Heating, ventilation, and air-conditioning units push wiring to its thermal limits—especially in commercial buildings. Lighting and Electrical Panels High-wattage lighting systems and control panels often rely on heat-resistant wiring to avoid insulation failure. Advantages of High Temperature Cables Why not just use regular cables and replace them often? Because that approach costs more in the long run. Safety Heat-resistant insulation drastically reduces fire risk, electrical shorts, and system failures. Longevity These cables last 2–5 times longer than standard wires in hot environments. Less replacement equals less downtime. Electrical Stability They maintain voltage integrity under thermal stress, ensuring consistent machine performance. Disadvantages & Limitations No technology is perfect. Cost Factors High temperature cables cost more upfront due to premium materials and complex manufacturing. Installation Challenges Some high-temp cables, especially fiberglass and mica types, require special handling during installation to avoid damage. High Temperature Cable vs Regular Cable Still unsure which one you need? Let’s make it clear. Performance Comparison Feature Regular Cable High Temp Cable Max Heat 80–105°C 150–1000°C Safety Moderate Very High Lifespan in Heat Short Long Cost Low Medium to High Cost vs Value While high temperature cables cost more initially, they save huge amounts on maintenance, downtime, and fire risk. How to Select the Right High Temperature Cable Choosing the wrong cable is like wearing winter clothes in a desert doesn’t end well. Temperature Range Know your operating temperature and always select a cable rated 20–30% higher than your maximum heat. Chemical Resistance If your environment has oils, acids, or solvents, choose fluoropolymer or silicone jackets. Flexibility & Mechanical Strength Dynamic applications require flexible insulation, while static installs can use rigid, high-strength sheathing. Installation Best Practices Even the best cable can fail if installed poorly. Cable Routing Tips Avoid sharp

Cartridge Heater Manufacturer Complete Industry Guide

In today’s fast-moving industrial world, heat plays a silent yet powerful role. From plastic molding to medical equipment, nothing runs smoothly without controlled heating. And right at the heart of these heating systems sits an unsung hero the cartridge heater. If you’ve ever wondered what a cartridge heater manufacturer really does and why this industry is growing so rapidly, you’re in the perfect place. Let’s break it all down in a simple, real-world way no boring technical overload, just useful, practical knowledge. What Is a Cartridge Heater? Think of a cartridge heater as a compact, powerful electric heater packed into a metal tube. It’s designed to slide right into drilled holes and deliver intense, focused heat exactly where it’s needed. Basic Working Principle A cartridge heater works by converting electrical energy into heat using a resistance wire coiled inside a metal sheath. Once powered, it heats up rapidly and transfers that heat directly into the surrounding material. Key Features of Cartridge Heaters High temperature resistance Compact and space-saving Fast heat-up time Extremely durable Role of a Cartridge Heater Manufacturer A cartridge heater manufacturer does much more than just “make heaters.” They engineer heat solutions. Design & Engineering Manufacturers calculate proper watt density, voltage, and dimensions based on end-use. Every heater is designed for performance and safety. Material Selection Premium stainless-steel sheaths, high-purity magnesium oxide insulation, and top-grade resistance wire ensure longevity and efficiency. Quality Control From resistance testing to insulation checks, every heater undergoes strict inspections before leaving the facility. Types of Cartridge Heaters Different industries demand different heat strengths so manufacturers produce several types. High-Density Cartridge Heaters Used in extreme temperature applications like plastic molds and die casting. Low-Density Cartridge Heaters Ideal for softer materials where gentle, even heating is needed. Miniature Cartridge Heaters Perfect for compact applications like medical devices and lab instruments. Square Cartridge Heaters Used when round heaters are not suitable for tight or flat surface installations. Key Components Used in Cartridge Heaters Every cartridge heater is built like a carefully layered sandwich. Heating Wire Usually made from nickel-chromium alloy for maximum heat resistance. Magnesium Oxide Insulation This powder ensures fast heat transfer while keeping electricity safely insulated. Stainless Steel Sheath Acts like armor protecting the heater from corrosion and mechanical damage. Manufacturing Process of Cartridge Heaters This is where the magic happens. Coil Winding Resistance wire is precisely wound to achieve uniform heating. Insulation Filling Magnesium oxide powder is packed around the coil for thermal conductivity. Swaging Process The heater is compressed under high pressure to remove air gaps and improve heat transfer. Sealing & Testing Ends are sealed, leads attached, and each unit is electrically tested for safety. Industries That Use Cartridge Heaters Cartridge heaters power countless industries without anyone even noticing. Plastic & Injection Molding They heat mold cavities to shape plastic parts perfectly. Packaging Industry Used in sealing machines for shrink wrapping and heat sealing. Medical Equipment Autoclaves, sterilizers, and diagnostic devices rely on precise heat. Food Processing From ovens to warmers, consistent heating keeps food safe and tasty. Importance of Custom Cartridge Heaters One-size-fits-all doesn’t work in industrial heating. Custom Diameters & Lengths Manufacturers build heaters to exact hole sizes for perfect fit. Watt Density Customization Different materials require different heating intensity. Voltage Customization From 12V to 480V manufacturers tailor heaters to power systems worldwide. Global Demand for Cartridge Heater Manufacturers The world is heating up industrially speaking. Growth in Automation More machines mean more heaters simple math. Rise of Smart Factories Modern industries want precise, responsive heating systems, driving demand upward. How to Choose the Right Cartridge Heater Manufacturer Not all manufacturers are created equal. Experience & Certification Look for ISO-certified manufacturers with proven industry experience. Custom Manufacturing Capabilities A good manufacturer can design to your exact specs. After-Sales Support Heaters are long-term investments. Technical support matters. Quality Standards in Cartridge Heater Manufacturing Good heaters follow strict quality rules. ISO Certifications Ensure process control and consistency. Electrical Safety Standards Guarantee shock protection, insulation strength, and reliable terminals. Advantages of Buying from a Professional Manufacturer Why risk cheaper, unreliable options? Longer Heater Life Premium materials equal longer operational life. Energy Efficiency Proper design reduces power consumption and heat loss. Application-Specific Performance Heaters engineered for your application work smarter not harder. Common Problems Solved by Cartridge Heaters These small heaters solve big industrial headaches. Uneven Heating Cartridge heaters deliver uniform temperature distribution. Slow Heat-Up Times They reach target temperatures quickly and efficiently. Energy Wastage Direct-contact heating minimizes energy loss. Future Trends in Cartridge Heater Manufacturing The future of heating is smarter and greener. Smart Heating Solutions Sensor-integrated heaters are entering the market. Energy-Efficient Designs Lower power consumption with higher heating efficiency is the goal. Why Local vs International Cartridge Heater Manufacturers Matter Choosing between local and overseas suppliers affects your business. Pricing Difference International options may be cheaper but hidden costs add up. Delivery Time Local manufacturers offer faster turnaround. Technical Support On-site support gives local manufacturers a strong advantage. Environmental Impact & Sustainability Modern manufacturers are going green. Eco-Friendly Materials Recyclable metals and safer insulation materials are being adopted. Low Energy Consumption High-efficiency heaters reduce carbon footprints significantly. Conclusion Choosing the right cartridge heater manufacturer is not just about buying a product it’s about investing in performance, safety, efficiency, and long-term reliability. Whether you’re in plastic molding, medical equipment, food processing, or automation, a high-quality cartridge heater can make the difference between smooth production and constant breakdowns. As industries continue to evolve and automation grows stronger, cartridge heaters will only become more essential. Working with an experienced, certified manufacturer ensures that your heating solutions are built to last, save energy, and deliver consistent results day after day. FAQs What is the average lifespan of a cartridge heater?With proper installation and usage, a high-quality cartridge heater can last anywhere from 3 to 7 years. Can cartridge heaters be custom-made?Yes, manufacturers offer full customization in terms of size, voltage, watt density, and lead options. Are cartridge heaters energy efficient?Absolutely. Their direct-contact heating

Thermocouple Manufacturer The Complete Guide to Precision Temperature Solutions

Temperature is the heartbeat of almost every industrial process. Whether you’re melting steel, baking bread, or generating electricity, one small fluctuation can change everything. That’s where thermocouples step in as silent guardians of accuracy. And behind every reliable temperature sensor stands a dependable thermocouple manufacturer. Think of a thermocouple manufacturer as the architect behind precision. They design, test, and produce sensors that must survive punishing heat, freezing cold, pressure, vibration, and corrosive environments without missing a beat. In this in-depth guide, we’ll walk through everything you need to know about thermocouple manufacturers, their processes, products, challenges, and why choosing the right one is crucial for your business. Introduction to Thermocouples What Is a Thermocouple? A thermocouple is a temperature sensor made by joining two dissimilar metal wires at one end. When that junction experiences heat, it generates a small voltage. That voltage corresponds directly to temperature. Simple? Yes. Powerful? Absolutely. It’s like a thermometer for harsh industrial worlds where glass thermometers would give up instantly. How Thermocouples Work The secret sauce is the See beck effect. When two different metals are joined and exposed to temperature differences, electrons get excited and start moving. This movement creates a measurable voltage. The thermocouple manufacturer calibrates this voltage to match temperature charts with extreme accuracy. Importance of a Reliable Thermocouple Manufacturer Accuracy and Safety In industries like oil & gas or chemical processing, temperature errors aren’t just expensive—they’re dangerous. A trusted thermocouple manufacturer ensures precise readings, reducing the risk of explosions, equipment failure, and product defects. Long-Term Performance Cheap thermocouples behave like cheap shoes they fail when you need them most. A reputable manufacturer uses premium alloys, advanced welding, and strict testing to ensure long operational life even in brutal conditions. Types of Thermocouples Manufactured Today Different applications demand different thermocouples. Here’s a breakdown of the most common types produced by manufacturers worldwide: Type K Thermocouple The most popular type. Wide temperature range, excellent durability, and affordable pricing. Ideal for furnaces, kilns, and general industrial use. Type J Thermocouple Perfect for low-to-medium temperatures. Common in plastic, packaging, and food industries. Type T Thermocouple Highly accurate at low temperatures. Frequently used in laboratories and cryogenic applications. Type N Thermocouple Designed for stability in high-temperature and oxidizing environments. A modern alternative to Type K. Type R, S, and B Thermocouples These are the royalty of thermocouples—made with platinum. They handle extreme heat in steel plants, glass furnaces, and aerospace testing. Industries That Rely on Thermocouple Manufacturers Manufacturing and Automation From CNC machines to injection molding, temperature feedback controls quality and consistency. Oil and Gas Industry Drilling operations and refineries operate at extreme conditions. Thermocouples ensure safe and efficient output. Power Generation Boilers, turbines, and reactors use thermocouples to keep everything within safe temperature limits. Food Processing Cooking, freezing, pasteurization every step must meet strict temperature controls. Medical and Laboratories Precision is everything. Even a 1-degree error can destroy an experiment. Key Materials Used in Thermocouple Manufacturing Nickel-Based Alloys Used in Type K, J, and N thermocouples. Strong, corrosion-resistant, and heat-tolerant. Platinum and Noble Metals Used in Type R, S, and B. Extremely accurate but costly. Insulation and Sheathing Materials Ceramic, fiberglass, PTFE, and stainless steel protect thermocouples from harsh environments. Manufacturing Process of Thermocouples Raw Material Selection Everything begins with precise alloy composition. A tiny impurity can destroy accuracy. Wire Drawing and Welding Ultra-thin wires are drawn and welded at micro-level precision. Insulation and Sheathing Protective layers make the thermocouple resistant to pressure, moisture, and chemicals. Calibration and Testing Every thermocouple is tested against known temperature points to ensure exact readings. Custom vs Standard Thermocouples When to Choose Standard Models Standard models are cost-effective and perfect for general-purpose applications. Benefits of Custom-Built Thermocouples Custom sizes, special insulation, rare alloys custom thermocouples are built exactly for your environment. Quality Standards Followed by Professional Thermocouple Manufacturers ISO Certification Guarantees manufacturing quality, traceability, and consistency. ASTM and IEC Standards Ensure global compatibility and safety performance. Role of Calibration in Thermocouple Manufacturing Why Calibration Matters Without calibration, a thermocouple is just two wires pretending to be a sensor. In-House vs Third-Party Calibration Top manufacturers maintain in-house calibration labs for faster turnaround and better-quality control. Common Applications of Thermocouples Furnaces and Kilns Extreme heat requires rugged and stable sensors. HVAC Systems Thermocouples regulate building temperatures and energy efficiency. Chemical Processing Accurate temperature prevents dangerous reactions. Automotive Sector Used in engines, exhaust systems, and battery management. Challenges Faced by Thermocouple Manufacturers High-Temperature Stability At 1200°C and above, even metals begin to misbehave. Signal Interference Electrical noise can distort small voltage signals. Harsh Environment Performance Moisture, corrosive gases, vibration everything works against the sensor. How to Choose the Best Thermocouple Manufacturer Experience and Expertise Years in the industry mean fewer mistakes and better consistency. Customization Capabilities Not every application fits standard models. Testing and Certification Ask for test reports. Real manufacturers love paperwork. After-Sales Support The relationship shouldn’t end at delivery. Global Thermocouple Manufacturing Market Overview Market Growth Trends Smart factories and automation are fueling rapid growth. Emerging Technologies Wireless sensors, AI-driven monitoring, and real-time cloud data. Importance of R&D in Thermocouple Manufacturing Innovation in Material New alloys improve lifespan and accuracy. Smart Temperature Sensors Self-diagnosing thermocouples are becoming a reality. OEM and Bulk Thermocouple Manufacturing Benefits for Large Industries Lower costs, dedicated production lines, and uniform quality. Cost Optimization Bulk ordering slashes per-unit price without sacrificing quality. Environmental and Safety Compliance in Thermocouple Production RoHS and REACH Compliance Protecting users and the environment simultaneously. Eco-Friendly Manufacturing Recycling metals and reducing production waste. Future of Thermocouple Manufacturing Industry AI and Automation Integration Smart factories powered by robotics and predictive maintenance. Wireless Temperature Sensing No wires, instant monitoring, remote diagnostics. Conclusion A thermocouple may look like a simple sensor, but behind its performance lies the expertise of a professional thermocouple manufacturer. From raw material selection to precision welding, from calibration to environmental testing, each step determines how accurately and reliably temperature is measured. As industries grow smarter and more automated, the demand

Band Heater Manufacturer the Complete Industry Guide

If you’ve ever worked in plastics, packaging, or industrial machinery, chances are you’ve already met the silent hero of heat control the band heater. But behind every high-performance band heater is a skilled band heater manufacturer working behind the scenes like a master craftsman shaping metal and heat into pure precision. In this complete guide, we’re diving deep into the world of band heater manufacturing how it works, why it matters, how to choose the right manufacturer, and what the future holds. Let’s turn up the heat. What Is a Band Heater? A band heater is a cylindrical heating device designed to wrap around pipes, barrels, nozzles, and cylindrical surfaces. Its job is simple but powerful deliver consistent, controlled heat directly where it’s needed. Think of it as a heated jacket that keeps industrial machines running at the perfect temperature. Why Band Heaters Are Critical in Industrial Heating Without proper heating, machines fail. Plastic won’t melt evenly. Extrusion lines slow down. Production quality drops. Band heaters ensure: Accurate temperature control Faster heat transfer Reduced energy wastage Stable production output They are the backbone of temperature-sensitive manufacturing. Manufacturing vs. Assembling A true band heater manufacturer doesn’t just assemble parts they engineer solutions. They: Design heaters from scratch Select insulation materials Wind resistance elements Test electrical and thermal performance This distinction separates premium manufacturers from basic suppliers. Custom vs. Standard Production While standard heaters are quick solutions, custom band heaters are precision tools built for unique machines, special voltages, and exact temperature ranges. Types of Band Heaters Mica Band Heaters Lightweight, affordable, and widely used. Ideal for standard industrial heating applications. Ceramic Band Heaters Designed for higher temperatures and longer lifespan. These are energy-efficient and perfect for heavy-duty use. Mineral Insulated Band Heaters Built for extreme conditions using magnesium oxide insulation. They offer excellent heat transfer and durability. Nozzle Band Heaters Compact and powerful, nozzle heaters are used in injection molding machines for precise melt flow control. Raw Materials Used in Band Heater Manufacturing Stainless Steel The outer shell is made of corrosion-resistant stainless steel to withstand high temperatures and harsh environments. Mica Insulation Mica provides excellent electrical insulation and heat resistance. Ceramic Insulation Used for higher temperature tolerance and improved energy efficiency. Nickel-Chromium Resistance Wire This is the heat-generating core that converts electricity into thermal power. Step-by-Step Band Heater Manufacturing Process Design & Engineering The process starts with dimensions, voltage requirements, watt density, and application needs. Insulation Placement Mica or ceramic insulation is layered carefully to ensure safety and heat efficiency. Element Winding Resistance wire is wound with extreme precision to ensure uniform heating. Clamping & Assembly Steel shells are shaped, clamped, and fitted with terminals. Quality Testing Each heater undergoes: High-voltage testing Resistance checks Heat distribution inspection Only flawless units move forward. Key Industries That Use Band Heaters Plastic Injection Molding Used to melt plastic granules smoothly and consistently. Extrusion Industry Ensures uniform heating along long barrels. Pharmaceutical Machinery For temperature-sensitive drug processing. Food Processing Equipment Helps control heating in packaging and sealing machines. Packaging Industry Essential for shrink wrapping and sealing operations. How to Choose the Right Band Heater Manufacturer Experience & Expertise An experienced manufacturer understands heat behavior and machine compatibility. Customization Capability Your machines aren’t generic—your heaters shouldn’t be either. Certifications & Quality Standards ISO standards and electrical safety certifications matter. After-Sales Support Great manufacturers stand by their products with real support. Importance of Custom Band Heaters Temperature Accuracy Custom heaters ensure exact heating without hot spots. Energy Efficiency Correct watt density reduces power consumption. Machine Compatibility Perfect fit means better heat transfer and longer machine life. Quality Control in Band Heater Manufacturing Electrical Safety Testing Leakage current testing prevents short circuits. Heat Distribution Checks Ensures the heater warms evenly around the surface. Durability & Stress Tests Heaters are tested under extreme thermal cycles for long-term reliability. Energy Efficiency & Innovation in Band Heaters Smart Temperature Sensors Modern band heaters integrate thermostats and sensors for precise monitoring. Low Power Consumption Designs Advanced insulation reduces heat loss by up to 30%. Export Market & Global Demand Asia as a Manufacturing Hub Asia dominates production due to cost efficiency and skilled labor. Europe & USA Market Demand High demand for quality-certified industrial heaters. Common Problems with Low-Quality Band Heaters Uneven Heating Leads to product defects and machine damage. Short Service Life Cheap materials mean frequent replacement. Machine Downtime Losses Poor heaters cause production shutdowns and profit loss. Cost Factors in Band Heater Manufacturing Material Quality Better materials = higher price but longer lifespan. Custom Design Charges Custom heaters cost more but save long-term expenses. Bulk Order Pricing Large orders reduce per-unit production cost. OEM & Private Label Band Heater Manufacturing Benefits of OEM Supply Manufacturers produce heaters under your brand name. Branding Opportunities You control the design, packaging, and market identity. Future Trends in Band Heater Technology AI Temperature Control Smart automation will dominate industrial heating. Eco-Friendly Materials Sustainable insulation and recyclable metals are shaping the future. Why Choosing the Right Band Heater Manufacturer Matters? Your production line is only as strong as its weakest heating element. Choosing the right manufacturer means: Higher efficiency Lower maintenance Consistent production Long-term cost savings Think of your band heater manufacturer not as a supplier but as an extension of your engineering team. Conclusion A band heater may look simple on the outside, but behind its compact design lies complex engineering, precision craftsmanship, and critical industrial value. The right band heater manufacturer doesn’t just create heating devices they create stability, efficiency, and production confidence. Whether you’re in plastics, packaging, food processing, or pharmaceuticals, investing in high-quality band heaters from a reliable manufacturer is one of the smartest decisions you can make for your business. After all, in industrial production, heat isn’t just power it’s precision. FAQs How long does a band heater typically last? With proper usage and quality materials, a band heater can last 2–5 years or more. What is the difference between mica and ceramic band

Cartridge Heater Manufacturers and Suppliers A Complete Guide

Cartridge heaters play one of the most crucial roles in modern industrial heating solutions. Whether you’re in plastic moulding, packaging, food processing, or heavy machinery, these compact heating elements offer reliability, precision, and high performance. What Are Cartridge Heaters? A cartridge heater is a cylindrical, tube-shaped heating element designed to deliver concentrated heat in small, confined areas. Think of them as the “power heaters” installed inside metal blocks, dies, and moulds to maintain consistent temperature. Why Cartridge Heaters Are Essential in Modern Industries Today’s industries rely heavily on precision heating. Cartridge heaters offer: Fast heating performance High watt density Perfect temperature accuracy This makes them ideal for production lines where speed and consistency matter. Types of Cartridge Heaters High-Watt Density Cartridge Heaters These heaters are engineered for high-temperature applications. They deliver strong, fast heat and are commonly used in industrial machines requiring intense heating. Low-Watt Density Cartridge Heaters Perfect for sensitive heating applications where too much heat can damage components. They offer stable and controlled heating. Swaged vs. Non-Swaged Cartridge Heaters Swaged: Dense insulation, faster heating, and longer life. Non-swaged: More economical and suitable for basic applications. Key Features of High-Quality Cartridge Heaters Temperature Control & Heating Speed Premium heaters reach the desired temperature quickly while maintaining stability. Material Quality High-grade stainless steel and nickel-chromium wires ensure durability and performance. Customization Options Top suppliers offer custom lengths, diameters, watt densities, and lead configurations based on industrial needs. Applications of Cartridge Heaters Packaging Industry Used in sealing machines and cutting systems for accurate and fast heating. Plastic Moulding Heaters ensure moulds stay at the right temperature for smooth production. Food Processing Helps maintain stable temperatures in cooking, drying, and processing machinery. Medical & Laboratory Equipment Used in sterilizers, analytic devices, and precision instruments. How to Choose the Best Cartridge Heater Manufacturers Manufacturing Standards Always choose a manufacturer that follows ISO and CE-certified production standards. Certifications & Quality Checks Ensure they conduct insulation resistance tests, watt density analysis, and temperature tests. Customer Support & After-Sales Service A reliable supplier provides guidance, warranty, and technical help when needed. Best Cartridge Heater Manufacturers and Suppliers China-Based Manufacturers China leads the global cartridge heater market due to: Advanced manufacturing High-quality materials Competitive pricing Top Chinese manufacturers supply millions of heaters worldwide. USA-Based Manufacturers Known for premium quality and high-end custom heaters. European Manufacturers Offer durable heaters with strict quality control. Why China Leads Global Cartridge Heater Supply China’s technology, skilled labour, and bulk production capacity make it ideal for buyers seeking both quality and affordability. Benefits of Buying from Reliable Suppliers Longer Heater Life Good manufacturers use quality insulation and heating wires. Increased Efficiency Reliable heaters heat faster and save electricity. Cost Savings Low maintenance and longer lifespan reduce replacement costs. How to Evaluate a Supplier Before Buying Product Testing Check temperature accuracy and durability. Sample Orders Always test samples before bulk orders. Check Online Reviews Buyer feedback reveals the supplier’s reliability. Pricing Guide for Cartridge Heaters Factors That Affect the Cost Size Watt density Customization Lead type Price Comparison: China vs Global Markets Chinese suppliers offer the most competitive rates while maintaining high quality. Tips for Maintaining Cartridge Heaters Installation Tips Ensure correct fit and avoid air gaps to prevent overheating. Safety Tips Use temperature controllers for safe operation. Cleaning & Maintenance Guidelines Regular checks increase heater lifespan. Future Trends in Cartridge Heater Manufacturing Smart Heating Technologies IoT-based heaters with auto temperature control. Eco-Friendly Heater Designs Manufacturing using recyclable materials and energy-efficient methods. Conclusion Cartridge heaters are essential for modern industrial operations, offering precision, durability, and performance. Choosing the right manufacturer ensures efficient production, cost savings, and long-term reliability. Whether buying from China, the USA, or Europe, always focus on quality, certifications, and customization options. FAQs 1. What is a cartridge heater used for? It is used for precision heating in machinery, moulds, packaging systems, and laboratory equipment. 2. Which country makes the best cartridge heaters? China, the USA, and Germany are globally leading suppliers. 3. How long does a cartridge heater last? With proper maintenance, it can last several months to years depending on usage. 4. Are cartridge heaters customizable? Yes, top manufacturers offer custom sizes, watt densities, and wiring options. 5. How do I maintain my cartridge heater? Install correctly, avoid moisture, and check temperature settings regularly.

Best Tubular Heater Manufacturer

Tubular heaters are among the most versatile and durable heating solutions used across industries. Whether it’s in HVAC systems, food processing, or oil refineries, these heaters provide consistent and efficient thermal performance. Finding a trusted tubular heater manufacturer ensures product longevity, efficiency, and safety. What Makes a Reliable Tubular Heater Manufacturer A professional tubular heater manufacturer doesn’t just sell products they deliver precision-engineered heating solutions. Reliable manufacturers focus on: Quality control: Each unit passes strict testing to ensure performance. Technology integration: Using CNC bending, TIG welding, and insulation filling techniques for precision. Customization: Tailored heaters for unique temperature and environmental needs. Types of Tubular Heaters Straight Tubular Heaters Ideal for insertion into ducts, molds, or ovens where linear heating is required. Finned Tubular Heaters Equipped with fins to enhance heat transfer and surface area, often used in air or gas heating applications. U-Shaped Tubular Heaters Commonly used in tanks or process vessels for uniform heating. Immersion Tubular Heaters Submerged directly into liquids such as water, oil, or chemicals. Flanged Tubular Heaters Designed for high-pressure and high-temperature systems, featuring robust mounting options. Cartridge and Flexible Heaters Used for compact spaces or applications requiring flexible heating elements. Applications of Tubular Heaters From industrial ovens to chemical baths, tubular heaters serve everywhere. Some key applications include: Food processing: For ovens, fryers, and packaging lines. Plastic moulding: Ensures even material flow and consistency. HVAC systems: Air duct and space heating. Oil & gas: Used in storage tanks, separators, and pipelines. Pharmaceutical: Sterilization and drying processes. Key Features and Benefits Long operational life with stainless steel or Incoloy sheaths. High efficiency with minimal energy waste. Compact design suitable for confined spaces. Easy maintenance and replacement. Corrosion and oxidation resistance, even in harsh conditions. How Tubular Heaters Work A resistance wire (usually nickel-chromium) is embedded in magnesium oxide and encased in a metal sheath. As electricity passes, the wire heats up, transferring energy through conduction and convection. This simple mechanism makes them extremely reliable. Choosing the Right Tubular Heater Key considerations include: Operating environment: Air, water, or oil. Watt density: Ensures optimal heat without overheating. Voltage and size: Must match system requirements. Material selection: Stainless steel for moisture; Incoloy for high-temperature use. Customization Options Manufacturers offer heaters in custom shapes, wattage’s, and mounting styles. Options include: Various diameters (6mm–25mm) Threaded fittings and flanges Integrated thermostats or thermocouples Manufacturing Process Overview Design and Engineering: Tailored to client specs. Material Selection: High-grade stainless steel or copper. Assembly: Sealing and filling with magnesium oxide. Testing: Electrical insulation and performance verification. Safety Standards and Certifications Top manufacturers comply with: ISO 9001: Quality management systems. CE and UL: Safety and performance certifications. RoHS compliance: Restriction of hazardous materials. Maintenance and Troubleshooting Common Issues Uneven heating → check watt density. Reduced output → inspect connections or scaling. Overheating → replace damaged thermostats. Maintenance Tips Keep heaters clean and free from corrosion. Schedule periodic testing for insulation resistance. Why Choose a Trusted Manufacturer Choosing a professional tubular heater manufacturer ensures: Reliable performance and longer lifespan Custom engineering support Affordable pricing with bulk orders Warranty and after-sales assistance Environmental Impact and Sustainability Modern tubular heaters are built for energy efficiency, reducing carbon footprint. Many manufacturers now use recyclable metals and eco-friendly production techniques. Global Market for Tubular Heaters The demand for industrial heaters is growing globally particularly in manufacturing, food, oil, and renewable energy sectors. Quality manufacturers export to Europe, Asia, and the Middle East, serving both standard and custom markets. Conclusion Tubular heaters are indispensable for reliable, efficient, and cost-effective heating. When sourced from a trusted manufacturer, you gain performance, durability, and full support for your industrial or commercial needs. Whether you need standard or custom-made heaters, choosing a professional supplier ensures your systems run safely and efficiently.

Gas Pipeline Heaters Manufacturers

Gas pipeline heaters play a crucial role in maintaining the optimal flow and temperature of gas during transmission. As natural gas travels through pipelines across long distances and varied climates, it can experience condensation, freezing, or viscosity issues. That’s where gas pipeline heater manufacturers come in offering reliable heating systems to ensure smooth operations, energy efficiency, and safety in the gas industry. What Are Gas Pipeline Heaters? Gas pipeline heaters are specialized equipment designed to maintain gas temperature in pipelines, preventing condensation and blockages caused by low temperatures. They are essential in ensuring uninterrupted gas flow, particularly in colder regions. Importance of Gas Pipeline Heaters Without proper heating, gas pipelines can face flow disruptions, pressure drops, and even equipment damage. High-quality heaters ensure: Consistent gas flow Prevention of hydrate formation Protection of valves and metering equipment Enhanced operational safety and efficiency Types of Gas Pipeline Heaters 1. Indirect Fired Heaters These heaters use a heat transfer fluid to warm the gas without direct contact with flames, providing safe and efficient heat exchange. 2. Electric Heaters Electric heaters are eco-friendly options offering precise temperature control, ideal for smaller installations. 3. Water Bath Heaters A popular type in the industry, water bath heaters use a fire-tube submerged in a water-glycol solution to heat gas indirectly. Key Features of Quality Gas Pipeline Heaters Top manufacturers focus on: High thermal efficiency Advanced temperature control systems Corrosion-resistant materials Easy maintenance design Compliance with international safety standards Applications of Gas Pipeline Heaters Gas pipeline heaters are used in: Natural gas transmission systems Compressor and metering stations Gas processing facilities LNG terminals Oil and gas exploration sites Top Gas Pipeline Heater Manufacturers Leading manufacturers in the industry include companies known for innovation, durability, and global compliance. They specialize in custom-designed heating systems suitable for various industrial applications, including energy, petrochemical, and offshore operations. Why Choose Reliable Manufacturers Selecting trusted gas pipeline heater manufacturers ensures: Better system reliability Reduced downtime Lower maintenance costs Compliance with environmental and safety regulations Technological Advancements Modern pipeline heaters are now equipped with smart control systems, digital monitoring, and automation features to ensure optimal performance and energy efficiency. Energy Efficiency and Sustainability Manufacturers today are focusing on sustainable designs that reduce energy consumption and carbon emissions, helping the gas industry align with global green energy goals. Maintenance and Safety Routine maintenance and built-in safety mechanisms, such as pressure relief valves and automatic shutdown systems, ensure long-term reliability and operational safety. Choosing the Right Heater Before purchasing, consider: Pipeline size and gas flow rate Environmental conditions Power availability Safety certifications Future Trends The future of gas pipeline heaters lies in IoT-enabled systems, AI-based predictive maintenance, and eco-friendly designs that support cleaner energy transitions. Conclusion Gas pipeline heaters are indispensable to the oil and gas sector, ensuring stable gas flow and operational safety. Partnering with reputable gas pipeline heater manufacturers guarantees efficient performance, advanced technology, and long-term value for industries worldwide. FAQs 1. What is the main purpose of a gas pipeline heater?To maintain gas temperature and prevent freezing or hydrate formation in pipelines. 2. Are gas pipeline heaters energy-efficient?Yes, modern heaters are designed with energy-saving technology and smart temperature controls. 3. Where are gas pipeline heaters commonly used?They are used in gas transmission stations, processing plants, and LNG facilities. 4. How often should gas pipeline heaters be maintained?Regular maintenance every 6–12 months is recommended to ensure peak performance. 5. Can electric heaters replace conventional gas heaters?For smaller or eco-focused operations, electric heaters offer an efficient alternative.