What is the Purpose of a Tubular Heater?

A tubular heater with thermostat is an essential component in various heating applications. Whether you’re dealing with industrial machinery or home appliances, understanding the role of this heating element can significantly enhance the efficiency of your operations. The tubular heater with thermostat provides controlled heat, ensuring that your equipment operates at optimal temperatures without the risk of overheating. How Does a Tube Heater Work? A tube heater operates by converting electrical energy into heat. This heat is then distributed evenly across the surface of the tube, making it ideal for applications that require consistent and reliable heat. Construction: Tube heaters are typically made of a metal sheath, such as stainless steel, which houses the heating element. The element inside is usually a coil of resistance wire, similar to that found in cartridge heaters. Thermostat Integration: The addition of a thermostat allows for precise temperature control. This prevents overheating, which can damage both the heater and the material being heated. Heat Distribution: The design of the tube allows for even heat distribution, making it suitable for applications where uniform heating is crucial. Applications of Tube Heaters Tube heaters are incredibly versatile and can be found in a wide range of applications. Here’s where they shine: Industrial Heating: Tube heaters are commonly used in industrial processes, such as drying, curing, and melting, where precise and reliable heat is required. HVAC Systems: In heating, ventilation, and air conditioning systems, tube heaters help maintain consistent temperatures, ensuring comfort and efficiency. Food Processing: Tube heaters play a critical role in food processing by providing controlled heat for cooking, baking, and maintaining the right temperature for food safety. Greenhouse Heating: Tube heaters are also used in greenhouses to provide consistent warmth, promoting healthy plant growth even in colder climates. Benefits of Using a Tube Heater with Thermostat Choosing a tubular heater with thermostat offers several advantages: Energy Efficiency: The thermostat allows the heater to maintain the desired temperature without consuming excess energy. This leads to lower energy costs and a more sustainable operation. Safety: The built-in thermostat prevents the heater from overheating, reducing the risk of fire or damage to the equipment. Longevity: By preventing overheating, the thermostat also extends the life of the heater, reducing the need for frequent replacements. Versatility: Tube heaters with thermostats can be used in a variety of applications, from industrial processes to residential heating, making them a versatile choice for different heating needs. Final Words The tubular heater with thermostat is a vital tool in various industries, providing controlled and consistent heat where it’s needed most. Understanding its purpose and benefits can help you make informed decisions about its use in your operations. With proper maintenance and the right choice of heater, you can ensure efficient and safe heating for years to come.

What is the Application of a Band Heater?

When working with machinery and industrial equipment, maintaining the right temperature is crucial for smooth operation. This is where a band heater plays a vital role. Designed to heat cylindrical surfaces, band heaters are indispensable in many industrial processes. If you are looking for reliable heating solutions, working with a trusted band heater manufacturer ensures you get the right equipment for your needs. Common Applications of Band Heaters Band heaters are versatile and find use in a variety of industries. Below are some of the most common applications: Plastic Injection Molding: In plastic molding, band heaters are used to maintain the correct temperature of the molds. This ensures that the plastic material flows smoothly and sets properly, resulting in high-quality finished products. Extrusion Processes: Band heaters are essential in extrusion processes, where materials like plastic or rubber are pushed through a mold to create products like pipes, sheets, or films. Maintaining the right temperature is crucial for ensuring the material’s consistency and preventing defects. Food and Beverage Industry: Band heaters help maintain the right temperature for food processing equipment, ensuring that products are cooked evenly and safely. They are also used in machinery like coffee urns and food warmers. Chemical and Pharmaceutical Industry: Band heaters are used to heat tanks and vessels, ensuring that chemicals and pharmaceuticals are processed at the correct temperatures. This is essential for reactions and formulations that require precise thermal conditions. Printing Industry: In the printing industry, band heaters help maintain the temperature of ink and rollers, ensuring that the printing process is smooth and the quality of the print is high. How to Choose the Right Band Heater Manufacturer Selecting the right band heater manufacturer is essential for ensuring that you get a product that meets your specific needs. Here are some factors to consider: Customization: A good manufacturer will offer custom options, allowing you to choose the right size, wattage, and sheath material for your application. Quality Control: Reliable manufacturers adhere to strict quality control standards, ensuring that every band heater is built to last and performs reliably. Technical Support: A manufacturer that offers technical support can help you select the right heater and troubleshoot any issues that may arise during installation or operation. Energy Efficiency: Look for manufacturers that design band heaters with energy efficiency in mind, as this can lead to cost savings and reduced environmental impact. Wrap Up Understanding what the application of a band heater is, and how it functions, is essential for anyone involved in industries that rely on precise temperature control. From plastic molding to food processing, band heaters play a critical role in ensuring that industrial processes run smoothly and efficiently. Working with a reputable band heater manufacturer like Cheri ensures that you get a reliable product tailored to your specific needs, backed by quality assurance and technical support. By following proper maintenance practices, you can extend the life of your band heater and keep your operations running at peak efficiency.

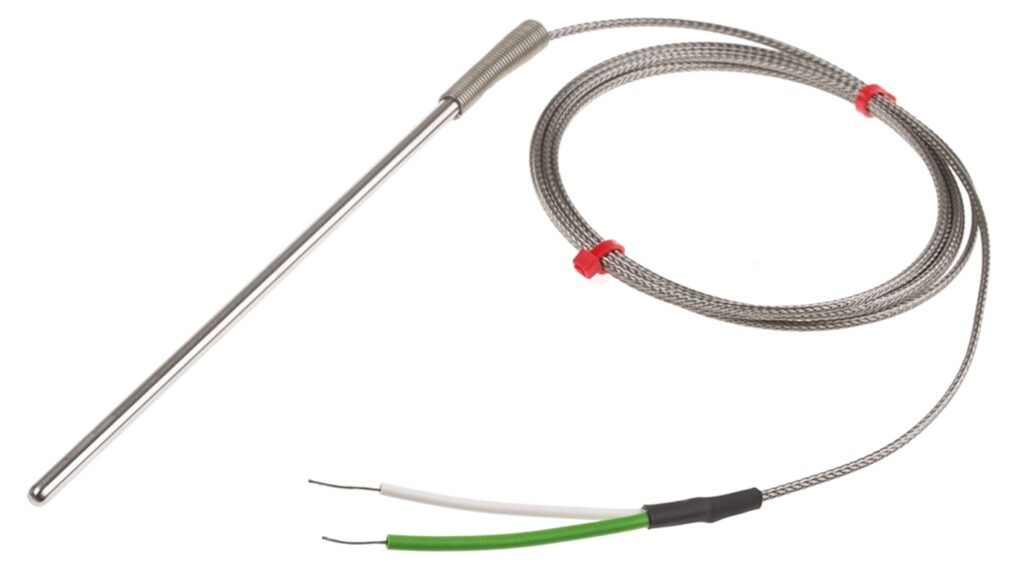

Where is a Thermocouple Used?

When considering the various devices that measure temperature, the thermocouple stands out for its versatility and reliability. Whether you are familiar with the work of a thermocouple manufacturer or just beginning to explore this field, understanding where thermocouples are used can provide valuable insight. Thermocouples are essential in many industries due to their ability to accurately measure extreme temperatures. How Does a Thermocouple Work? A thermocouple consists of two different metals joined at one end. When these metals experience a temperature difference, they generate a small electrical voltage. This voltage is then interpreted to measure the temperature. The simplicity of this design allows thermocouples to be both durable and responsive, making them suitable for various applications. Durability: Thermocouples are built to withstand harsh environments, from extreme heat to corrosive conditions. Versatility: They can measure temperatures ranging from very low to extremely high, depending on the metals used. Quick Response: The small size and direct contact of thermocouples allow them to respond quickly to temperature changes. Applications of Thermocouples in Different Industries Thermocouples are used across a wide range of industries, each with unique requirements and challenges. 1. Industrial Manufacturing In manufacturing, controlling temperature is critical for ensuring product quality. Thermocouples are used in: Furnaces and Kilns: To monitor and control the high temperatures required for metalworking and ceramics. Plastic Extrusion: Where precise temperature control is needed to shape and form plastic materials. Heat Treatment: To ensure that metals are heated to the correct temperature for processes like hardening or annealing. 2. Aerospace Industry In the aerospace sector, the ability to measure temperature accurately is crucial for safety and performance: Engines: Thermocouples monitor the temperatures in jet engines, ensuring they operate within safe limits. Exhaust Systems: They measure the temperature of exhaust gases to assess engine performance and emissions. Spacecraft: Thermocouples are used in spacecraft to monitor critical systems, ensuring they function correctly in the extreme conditions of space. 3. Medical Field Thermocouples also play a vital role in medical equipment, where precise temperature measurement is often a matter of life and death: Sterilization Equipment: They monitor the high temperatures needed to sterilize medical instruments. Incubators: Thermocouples ensure that the temperature inside infant incubators remains stable and safe. Cryotherapy: They are used in cryotherapy chambers to monitor the extremely low temperatures required for treatment. Why Should I Choose a Thermocouple Manufacturer? Choosing the right thermocouple manufacturer can make a significant difference in the performance and reliability of the thermocouples you use. Here’s why: Customization: A good manufacturer can provide thermocouples tailored to your specific needs, whether that means different metal combinations or special sheathing materials. Quality Control: Reputable manufacturers have strict quality control processes to ensure that each thermocouple meets industry standards. Technical Support: Expert manufacturers offer support to help you select the right type of thermocouple for your application and assist with any issues that arise during use. Types of Thermocouples and Their Specific Uses Different types of thermocouples are designed for specific applications, depending on the materials used: Type K (Nickel-Chromium / Nickel-Alumel): Commonly used in general-purpose applications due to its wide temperature range and affordability. Type J (Iron / Constantan): Often used in older equipment, it’s suitable for lower temperature applications. Type T (Copper / Constantan): Best for low-temperature measurements, such as in cryogenics. Type S (Platinum Rhodium / Platinum): Used in high-temperature applications, like in the aerospace industry and laboratory settings. Maintenance and Care for Thermocouples To ensure your thermocouples function correctly and last as long as possible, regular maintenance is essential: Regular Inspections: Check thermocouples for signs of wear, corrosion, or damage. Calibration: Regularly calibrate thermocouples to ensure accuracy, especially in critical applications. Proper Installation: Ensure thermocouples are installed correctly, with secure connections and appropriate protective sheathing. Wrap Up Understanding where a thermocouple is used offers insight into the importance of this simple yet essential device in various industries. From manufacturing to aerospace and medical applications, thermocouples provide the precise temperature measurements necessary for safe and efficient operations. Partnering with a reliable thermocouple manufacturer ensures that you receive high-quality, customized solutions tailored to your specific needs. With proper care and maintenance, thermocouples can provide accurate temperature readings for many years, making them an invaluable tool in countless applications.

What is a Cartridge Heater?

A cartridge heater is an essential tool in various industries, known for its ability to deliver precise, localized heat. Whether you’re involved in manufacturing or exploring options for heating solutions, understanding the importance of choosing a reliable Cartridge Heater Manufacturer is crucial. Cartridge heaters are not just simple devices; they are carefully engineered to provide efficient heating for specific applications. How Do Cartridge Heaters Work? Cartridge heaters are designed to transfer heat effectively to their surroundings, making them ideal for heating metal parts or molds. Here’s a closer look at how they function: Construction: The core of a cartridge heater is a resistance wire made of nickel-chromium, which converts electrical energy into heat. This wire is tightly wound around a ceramic core and encased in a metal sheath, usually made of stainless steel. The sheath protects the heater and ensures even heat distribution. Insulation: The resistance wire is insulated with magnesium oxide, which not only serves as an electrical insulator but also enhances thermal conductivity. This allows the heat generated by the wire to transfer efficiently to the sheath and subsequently to the surrounding material. Design: Cartridge heaters are designed to fit snugly into drilled holes, ensuring close contact with the material being heated. This design maximizes heat transfer and minimizes energy loss. Types of Cartridge Heaters Understanding the different types of cartridge heaters can help in selecting the right one for your needs: High-Density Cartridge Heaters: These heaters offer a high watt density, making them suitable for applications that require rapid heating and high temperatures. Low-Density Cartridge Heaters: Used in applications where lower temperatures are sufficient, these heaters are ideal for sensitive materials. Split-Sheath Cartridge Heaters: Designed to expand when heated, these heaters ensure better contact with the surrounding material, improving heat transfer efficiency. Why Choose a Reputable Cartridge Heater Manufacturer? Selecting a trustworthy Cartridge Heater Manufacturer like Cheri is critical for ensuring the quality and performance of your heaters. Here’s why: Customization: A good manufacturer can provide customized solutions tailored to your specific needs, whether you require a particular size, wattage, or material. Quality Control: Reputable manufacturers adhere to strict quality control standards, ensuring that each heater is reliable and long-lasting. Technical Expertise: With the right manufacturer, you gain access to expert advice and support, helping you choose the best heater for your application and troubleshoot any issues. Durability: High-quality materials and construction techniques result in heaters that can withstand harsh conditions and last longer, reducing the need for frequent replacements. Maintenance Tips for Cartridge Heaters Proper maintenance can extend the life of your cartridge heaters and ensure they perform optimally: Regular Checks: Inspect heaters regularly for signs of wear, such as discoloration or damaged wires. Correct Installation: Ensure that the heater is installed snugly in the drilled hole to optimize heat transfer and prevent damage. Temperature Control: Use temperature controllers to prevent overheating, which can damage both the heater and the material it’s heating. Clean Environment: Keep the heater and its surroundings clean to prevent contamination that could affect performance. Wrap Up Understanding what a cartridge heater is and how it functions is essential for anyone involved in industries that require precise heating solutions. By selecting a reliable Cartridge Heater Manufacturer, you can ensure that your operations run smoothly and efficiently. With the right maintenance practices, your cartridge heaters can provide consistent performance, helping you achieve the desired results in your applications.

5 Applications of Finned Tubular Heater in Industries

A finned tubular heater always stands out as a powerful and efficient solution in industrial applications. This unique heating device has gained popularity across various sectors due to its versatility and effectiveness. From food processing to aerospace, the Finned Tubular Heater is making waves in how industries approach their heating needs. 1. Food Processing: Maintaining Optimal Temperatures The food industry relies heavily on precise temperature control to ensure product quality and safety. Finned Tubular Heaters play a crucial role in this sector. Uniform heating: The fins on these heaters help spread heat evenly, preventing hot spots that could spoil food. Quick temperature adjustments: Rapid heating and cooling capabilities allow for swift changes in production lines. Sanitary design: The smooth surface of these heaters makes them easy to clean, meeting strict hygiene standards. These heaters are also used in: Chocolate tempering machines Industrial fryers Food packaging equipment The ability to maintain steady temperatures within 1°C has made Finned Tubular Heaters a go-to choice for food processors aiming for top-notch quality. 2. Aerospace: Defrosting and De-icing The aerospace industry faces unique challenges when it comes to heating, especially in harsh weather conditions. Finned Tubular Heaters have found an important place in this field. Aircraft de-icing: These heaters are used in ground equipment to quickly melt ice on aircraft surfaces. Runway heating: Embedded in runway surfaces, they prevent ice formation and ensure safe takeoffs and landings. Sensor protection: Critical sensors on aircraft are kept ice-free using these efficient heaters. The heaters’ ability to operate in extreme cold, sometimes as low as -40°C, makes them ideal for aerospace applications. Their durability in harsh conditions has led to a 50% increase in their use in airport ground equipment over the past five years. 3. Plastic Manufacturing: Precision Molding The plastic industry relies on exact temperature control for molding and extrusion processes. Finned Tubular Heaters excel in this area. Even heat distribution: The finned design ensures uniform heating across molds, preventing defects. Energy efficiency: These heaters transfer heat more effectively, reducing power consumption. Compact size: Their slim profile allows for installation in tight spaces within molding machines. These heaters are also used in: Plastic extrusion lines Blow molding machines Thermoforming equipment The precision offered by Finned Tubular Heaters has led to a 25% increase in their adoption in the plastic industry over the past three years. 4. HVAC Systems: Efficient Air Heating Heating, Ventilation, and Air Conditioning (HVAC) systems benefit greatly from the use of Finned Tubular Heaters. Compact design: These heaters fit easily into ductwork, saving space in HVAC installations. Quick response: They heat up rapidly, allowing for fast temperature adjustments in buildings. Low maintenance: Their simple design means fewer parts that can break down or need replacing. These heaters are also used in: Industrial dryers Air curtains Heat recovery systems The efficiency of Finned Tubular Heaters has led to a 40% increase in their use in commercial HVAC systems since 2020. 5. Chemical Processing: Maintaining Reaction Temperatures In the chemical industry, maintaining precise temperatures is crucial for successful reactions and product quality. Corrosion resistance: Many Finned Tubular Heaters are made with materials that resist chemical corrosion. Explosion-proof options: Special models are available for use in hazardous environments. Fine temperature control: These heaters can maintain temperatures within 0.5°C, crucial for sensitive chemical processes. These heaters are also used in: Distillation columns Storage tank heating Pipeline pre-heating The reliability of Finned Tubular Heaters in maintaining exact temperatures has led to a 35% increase in their adoption in the chemical processing industry over the past four years. Final Words Finned Tubular Heaters have proven their worth across various industries. Their versatility, efficiency, and precision make them an excellent choice for many heating applications. As technology advances, we can expect to see even more innovative uses for these powerful heating devices. From food processing to chemical reactions, Finned Tubular Heaters are helping industries improve their processes, reduce costs, and enhance product quality.

5 Reasons Why You Need a Mold Cartridge Heater Manufacturer for Manufacturing Needs

Mold cartridge heater manufacturers are essential partners in optimizing manufacturing processes. These specialists design, produce, and supply heaters tailored to specific industrial needs, ensuring precise temperature control and efficient heat transfer. Whether you’re in the plastics, rubber, or food industry, collaborating with a reliable mold cartridge heater manufacturer is crucial for achieving production excellence. Reason 1: Consistent and Precise Temperature Control Maintaining consistent and precise temperature control is paramount in manufacturing. Mold cartridge heaters excel in this area, offering several advantages: Uniform Heat Distribution: Cartridge heaters are designed to distribute heat evenly across the mold cavity, preventing hot or cold spots. This uniformity is essential for producing products with consistent dimensions and quality. Rapid Heat-Up and Cool-Down Times: These heaters quickly reach the desired temperature, reducing cycle times and increasing production efficiency. Similarly, they cool down rapidly, allowing for faster mold turnover. Accurate Temperature Regulation: With advanced temperature controllers, mold cartridge heaters can maintain precise temperature settings, ensuring product consistency and minimizing defects. Reason 2: Enhanced Product Quality High-quality products are the cornerstone of business success. Mold cartridge heaters contribute significantly to product quality by: Preventing Defects: Consistent temperature control reduces the risk of defects such as warping, shrinkage, and burns. This leads to a higher percentage of acceptable products and less waste. Improving Product Performance: Precise temperature management can enhance product performance characteristics, such as strength, durability, and flexibility. Meeting Industry Standards: Many industries have stringent quality standards. Mold cartridge heaters help manufacturers meet these requirements by ensuring product consistency and reliability. Reason 3: Increased Production Efficiency Efficiency is key to maximizing profits in manufacturing. Mold cartridge heaters boost production efficiency through: Reduced Cycle Times: Faster heat-up and cool-down times translate to shorter cycle times, allowing for more production runs within a given period. Optimized Energy Consumption: Efficient heat transfer minimizes energy waste, leading to lower operating costs. Improved Equipment Uptime: Reliable mold cartridge heaters reduce downtime caused by equipment failures, maintaining production continuity. Reason 4: Versatility and Adaptability Mold cartridge heaters are incredibly versatile and can be adapted to various manufacturing processes and equipment: Wide Range of Sizes and Wattages: Cartridge heaters are available in various sizes and wattages to suit different mold cavities and heating requirements. Customizable Designs: Manufacturers can often customize cartridge heaters to meet specific application needs, ensuring optimal performance. Easy Installation and Replacement: These heaters are relatively simple to install and replace, minimizing downtime and maintenance costs. Reason 5: Long Lifespan and Durability Investing in high-quality equipment is essential for long-term profitability. Mold cartridge heaters offer: Durable Construction: Constructed from robust materials, cartridge heaters can withstand harsh manufacturing environments and temperature fluctuations. Extended Lifespan: With proper care and maintenance, mold cartridge heaters can have a long lifespan, reducing replacement costs. Cost-Effective Solution: While the initial investment might be higher, the long-term benefits in terms of efficiency, product quality, and reduced downtime make mold cartridge heaters a cost-effective choice. Last Word Mold cartridge heater manufacturers are invaluable partners in achieving manufacturing excellence. By providing custom-designed, high-performance heaters, these experts help businesses optimize production processes, enhance product quality, and improve overall efficiency. If you’re looking to elevate your manufacturing operations, collaborating with a reputable mold cartridge heater manufacturer will be your best decision.

5 Reasons Why You Need a CO2 Heater

CO2 Heater Manufacturer are increasingly gaining recognition for their innovative heating solutions. While the concept might be new to some, the benefits are undeniable. Let’s explore five compelling reasons why you should consider a CO2 heater for your heating needs. Reason 1: Energy Efficiency: A Greener Heat Source Energy costs are on the rise, making energy efficiency a top priority for homeowners and businesses alike. CO2 heaters offer a compelling solution. High Thermal Efficiency: CO2 heaters convert a significant portion of energy into heat, minimizing waste. Lower Operating Costs: Compared to traditional electric or gas heaters, CO2 heaters can lead to substantial savings on energy bills. Reduced Carbon Footprint: By utilizing CO2 as a heat source, these heaters contribute to a smaller environmental impact. Reason 2: Precise Temperature Control: Comfort at Your Fingertips Maintaining a comfortable indoor temperature is essential for well-being and productivity. CO2 heaters excel in providing precise temperature control. Accurate Temperature Settings: CO2 heaters allow you to set and maintain your desired temperature with high accuracy. Even Heat Distribution: These heaters distribute heat evenly throughout the space, creating a consistent and comfortable environment. Rapid Heating: CO2 heaters reach the desired temperature quickly, eliminating the need to wait for prolonged warm-up times. Reason 3: Safety First: A Reliable Heating Solution Safety is paramount when choosing a heating system. CO2 heaters prioritize safety without compromising performance. Clean Combustion: CO2 heaters produce minimal emissions, reducing the risk of indoor air pollution. Flameless Operation: Unlike traditional gas or oil heaters, CO2 heaters operate without an open flame, minimizing fire hazards. Temperature Sensors: Built-in sensors monitor and regulate temperature, preventing overheating and ensuring safe operation. Reason 4: Versatility: Adapting to Your Needs CO2 heaters are not limited to specific applications. Their versatility makes them suitable for various environments. Residential Use: Perfect for heating homes, apartments, and condos. Commercial Applications: Ideal for offices, retail spaces, and industrial settings. Outdoor Spaces: Certain models can be used to heat outdoor areas, extending your enjoyment of outdoor spaces. Reason 5: Eco-Friendly Heating: A Sustainable Choice Environmental concerns are at the forefront of many people’s minds. CO2 heaters offer an eco-friendly heating option. Reduced Carbon Emissions: By utilizing CO2, these heaters contribute to lower greenhouse gas emissions. Sustainable Energy Source: CO2 can be captured and reused, making it a sustainable heat source. Quiet Operation: CO2 heaters operate quietly, reducing noise pollution. Final Words CO2 heaters offer a compelling combination of energy efficiency, precise temperature control, safety, versatility, and environmental friendliness. While still a relatively new technology, their benefits are undeniable. As we strive for more sustainable and efficient heating solutions, CO2 heaters emerge as a promising option.

Best Band Heater: A Manufacturer Guide

Choosing the right band heater manufacturer can be overwhelming. With countless options available, it’s crucial to understand the nuances of band heaters and the factors to consider when selecting a manufacturer. This guide will equip you with the knowledge to make informed decisions. Understanding Band Heaters Band heaters are cylindrical heating elements that wrap around cylindrical surfaces to provide even heat distribution. Commonly used in industries like plastics, food processing, and chemical processing, band heaters are essential for maintaining optimal temperatures in various applications. Key Components of a Band Heater A typical band heater consists of: Sheath: The outer protective layer is usually made of stainless steel. Insulation: Material between the sheath and heating element, preventing heat loss. Heating Element: The core component that generates heat, often made of nickel-chrome alloy. Terminals: Connection points for power supply. Types of Band Heaters Band heaters are categorized based on their insulation material: Mica Band Heaters: Use mica as insulation, offering good heat transfer and durability. Ceramic Band Heaters: Employ ceramic insulation, providing excellent heat resistance and longevity. Mineral Insulated Band Heaters: Utilize magnesium oxide insulation, which is suitable for high temperatures and corrosive environments. Factors to Consider When Choosing a Band Heater Several factors influence the selection of a band heater: Temperature Requirements: Determine the maximum operating temperature needed. Wattage: Calculate the required wattage based on the heating area and the desired temperature. Voltage: Match the heater’s voltage to your power supply. Dimensions: Ensure the heater’s dimensions align with the cylindrical surface. Environment: Consider the operating environment, including temperature, humidity, and corrosive substances. Selecting the Right Band Heater Manufacturer A reliable band heater manufacturer is crucial for the success of your application. Look for these qualities: Experience and Expertise: Choose a manufacturer with a proven track record in the industry. Customization Capabilities: A manufacturer that offers custom solutions can meet specific needs. Quality Control: Ensure rigorous quality control measures are in place. Material Selection: The manufacturer should offer a variety of materials for different applications. After-Sales Support: Excellent customer service and technical assistance are essential. Best Practices for Using Band Heaters To maximize the lifespan and performance of your band heaters: Proper Installation: Follow manufacturer guidelines for installation. Regular Inspection: Check for signs of wear or damage. Temperature Control: Use thermostats or controllers to maintain optimal temperatures. Cleanliness: Keep the heater clean to prevent overheating. Safety Considerations Band heaters can pose safety risks if not handled properly: Wear Protective Gear: Use gloves and safety glasses when handling hot heaters. Proper Grounding: Ensure the heater is grounded to prevent electrical shocks. Ventilation: Provide adequate ventilation to avoid overheating. Fire Safety: Keep flammable materials away from the heater. Wrap Up Selecting the right band heater and manufacturer is vital for the success of your heating application. You can ensure optimal performance and longevity by understanding the different types of band heaters, considering key factors, and following safety guidelines.

Ultimate Guide to Tubular Heaters with Thermostat

A tubular heater with thermostat is more than just a heating device; it’s a tailored climate control solution. It’s the unsung hero of many spaces, delivering consistent warmth without breaking the bank. But with countless options flooding the market, choosing the right one can feel like searching for a needle in a haystack. Fear not! This guide will illuminate the path, transforming you from a heating novice to a thermostat-savvy expert. Understanding Tubular Heaters with Thermostat At its core, a tubular heater is a long, slender heating element encased in a protective sheath. It’s often made of aluminum or stainless steel. The “tubular” part refers to its shape, while the “heater” part signifies its function – to generate heat. But what truly sets it apart is the thermostat. This intelligent companion ensures your space stays at the desired temperature, preventing overheating and optimizing energy consumption. How Tubular Heaters with Thermostat Work The magic happens within the heater’s core. Electricity flows through the resistive element, generating heat. This heat is then transferred to the surrounding environment. The thermostat, acting as the brain of the operation, continuously monitors the temperature. If it drops below the set point, it signals the heater to turn on. Conversely, if the temperature rises above the set point, it switches off. This constant cycle maintains a steady temperature. Types of Tubular Heaters with Thermostat Not all tubular heaters are created equal. Understanding the different types is crucial for selecting the perfect fit. Standard Tubular Heaters: These are the most common type, offering basic heating functionality with a thermostat. They’re ideal for general-purpose heating in spaces like garages, workshops, or greenhouses. Explosion-Proof Tubular Heaters: Designed for hazardous environments, these heaters are built to withstand explosive atmospheres. They are commonly used in industrial settings. Waterproof Tubular Heaters: Perfect for damp areas, these heaters have a protective coating to prevent water damage. They are often used in bathrooms, kitchens, or outdoor spaces. Factors to Consider When Choosing a Tubular Heater with Thermostat Selecting the right tubular heater involves several factors: Size of the Area: The heater’s wattage should match the room’s size to ensure efficient heating. Desired Temperature: Consider the ideal temperature for your space and choose a heater with a suitable thermostat range. Mounting Options: Wall-mounted, floor-standing, or portable options are available based on your preferences. Safety Features: Look for features like overheat protection, tip-over switches, and IP ratings for safety. Energy Efficiency: Consider the heater’s energy consumption to minimize utility bills. Installation and Maintenance Proper installation is essential for optimal performance and safety. Most tubular heaters come with installation instructions. If you’re unsure, consult a professional electrician. Regular maintenance is key to prolonging the heater’s lifespan. Clean the heater regularly to remove dust and debris. Check the thermostat’s accuracy periodically. If you notice any issues, contact the manufacturer or a qualified technician. Common Applications of Tubular Heaters with Thermostat Tubular heaters with thermostats find applications in various settings: Residential: Heating garages, basements, workshops, and bathrooms. Commercial: Maintaining temperature in warehouses, factories, and retail spaces. Agricultural: Providing warmth for livestock, greenhouses, and poultry farms. Industrial: Preventing frost in pipes, tanks, and equipment. Safety Tips for Using Tubular Heaters Never leave a heater unattended, especially when children or pets are present. Keep combustible materials away from the heater. Use the heater on a stable, level surface. Regularly inspect the power cord for damage. By understanding the nuances of tubular heaters with thermostats, you can make an informed decision and enjoy the benefits of consistent warmth in your space.

CO2 Heaters: Find the Perfect Model for Your Needs

CO2 heater manufacturers offer a variety of models to suit different applications. Choosing the right CO2 heater can significantly impact your operation’s efficiency and safety. Understanding the key factors and available options is crucial. Let’s explore the different types of CO2 heaters, their functionalities, and how to select the ideal model for your specific needs. Understanding CO2 Heaters A CO2 heater is a device designed to maintain a consistent temperature for carbon dioxide gas. It prevents the gas from cooling and condensing, which can lead to operational issues. These heaters are commonly used in welding, industrial processes, and other applications where CO2 gas is essential. Types of CO2 Heaters There are primarily three main types of CO2 heaters: 1. Inline CO2 Heaters Inline CO2 heaters are installed directly into the gas line. They offer continuous heating of the gas as it flows through the system. These heaters are ideal for applications requiring consistent and precise temperature control. Benefits: Efficient, compact, and easy to install. Drawbacks: Can be more expensive than other options. 2. Regulator-Mounted CO2 Heaters These heaters are integrated into the CO2 regulator. They provide localized heating to prevent moisture buildup within the regulator itself. Benefits: Cost-effective, simple to use, and protects the regulator. Drawbacks: Limited heating capacity compared to inline heaters. 3. External CO2 Heaters External CO2 heaters are standalone units that heat the gas before it enters the system. They offer flexibility in terms of placement and heating capacity. Benefits: High heating capacity, versatile, and easy to maintain. Drawbacks: Larger footprint and potentially higher installation costs. Factors to Consider When Choosing a CO2 Heater Several factors influence the selection of a CO2 heater: Gas Flow Rate: The volume of CO2 gas passing through the system determines the required heater capacity. Temperature Requirements: The desired gas temperature is crucial for proper operation. Installation Space: Available space for the heater will affect the choice of model. Budget: Consider the initial cost and ongoing operating expenses. Safety Considerations: Ensure the heater complies with safety standards and regulations. Additional Features and Considerations Some CO2 heaters offer additional features to enhance performance and convenience: Temperature Control: Adjustable temperature settings for precise control. Safety Features: Overheating protection and thermal cut-off switches. Compact Design: Space-saving options for limited areas. Easy Installation: User-friendly design for quick setup. Maintenance and Safety Proper maintenance is essential for the longevity and efficiency of your CO2 heater. Regular cleaning, inspection, and replacement of worn parts are crucial. Safety should always be a top priority. Follow the manufacturer’s guidelines and adhere to safety regulations. Wrap Up Selecting the right CO2 heater is essential for optimal system performance and efficiency. By understanding the different types, considering key factors, and prioritizing safety, you can make an informed decision. Investing in a high-quality CO2 heater can significantly improve your operation’s productivity and reliability.