What is a Cartridge Heater: A Comprehensive Guide

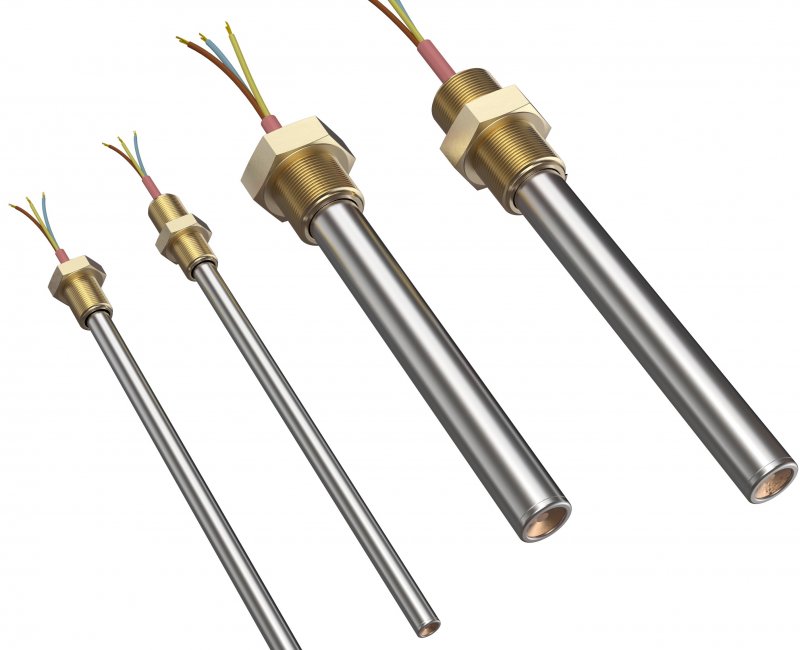

Heating solutions come in various forms, but few are as versatile and efficient as a cartridge heater. These compact powerhouses of heat generation have revolutionized countless industries. Cartridge heaters are crucial in maintaining precise temperatures from manufacturing to food processing. Let’s explore the world of a cartridge heater and its features, applications, and benefits. Understanding Cartridge Heaters Cartridge heaters are cylindrical heating elements designed for insertion into drilled holes or cavities. They provide localized heating in a variety of industrial and commercial applications and are known for their high watt density and ability to transfer heat efficiently. Key Components of a Cartridge Heater Heating Element: Typically made of nickel-chromium resistance wire Insulation: Usually magnesium oxide (MgO) for excellent heat transfer Sheath: Outer metal casing, often stainless steel or Incoloy Lead Wires: For connecting to a power source End Seal: Protects internal components from moisture and contaminants Cartridge heaters are designed to maximize heat transfer while maintaining durability. Their construction allows for efficient heating in confined spaces. How Cartridge Heaters Work The operation of a cartridge heater is based on simple yet effective principles. When an electrical current passes through the resistance wire, it generates heat, which is then transferred through the insulation to the outer sheath. Heat Transfer Process Electrical energy converts to heat in the resistance wire Heat transfers through the insulation to the metal sheath The sheath conducts heat to the surrounding material or medium Types of Cartridge Heaters Cartridge heaters come in various types to suit different applications. Here are some common varieties: Standard Cartridge Heaters: General-purpose heaters for most applications High-Watt Density Cartridge Heaters: For applications requiring intense heat Swaged Cartridge Heaters: Offer improved heat transfer and longer life Miniature Cartridge Heaters: For small spaces and precision heating Customized Cartridge Heaters: Tailored to specific application requirements Applications of Cartridge Heaters The versatility of cartridge heaters makes them suitable for a wide range of industries. Here are some common applications: Plastic Processing: Heating molds and nozzles in injection molding Food Industry: Maintaining temperatures in food processing equipment Medical Equipment: Sterilization and temperature control in medical devices Aerospace: Heating components in aircraft and spacecraft Packaging: Sealing and shrink-wrapping processes Automotive: Engine block heating and component testing 3D Printing: Maintaining precise temperatures for material extrusion Benefits of Using a Cartridge Heater Cartridge heaters offer several benefits that make them popular across industries: Compact Size: Fit easily into small spaces High Watt Density: Provide intense heat in a small package Precise Temperature Control: Allow for accurate heating Durability: Designed to withstand harsh industrial environments Versatility: Suitable for a wide range of applications Energy Efficiency: Concentrate heat where it’s needed most Easy Installation: Simple to insert and replace Selecting the Right Cartridge Heater Choosing the appropriate cartridge heater is crucial for optimal performance. Consider the following factors: Watt Density: Determine the heat output required Diameter and Length: Ensure proper fit in the application Sheath Material: Choose based on the operating environment Voltage: Match the heater to your power supply Temperature Requirements: Consider maximum operating temperature Special Features: Such as thermocouples or moisture resistance Energy Efficiency and Cost Considerations Cartridge heaters can be an energy-efficient heating solution when used correctly. Here’s why: Targeted Heating: Concentrates heat where it’s needed most Precise Control: Allows for accurate temperature management Quick Heat-Up: Reduces energy waste during warm-up periods Longevity: Quality cartridge heaters have a long operational life While the initial cost of a cartridge heater may be higher than that of some alternatives, its efficiency and longevity often result in long-term cost savings. Wrap Up As heating technology evolves, we expect even more cartridge heater design and functionality innovations. For now, these efficient and reliable heaters remain at the forefront of industrial and commercial heating solutions. Whether you’re considering cartridge heaters for a new application or looking to optimize your current heating processes, these versatile devices offer many benefits. Their ability to provide concentrated, controlled heat in a compact package makes them a valuable tool in our increasingly technology-driven world.

What is a Brass Band Heater: A Comprehensive Guide

A brass band heater is a versatile and powerful heating solution for industrial efficiency. The device plays a crucial role in countless manufacturing processes, from plastics to food processing. Brass band heaters are the unsung heroes of temperature control. Let’s learn what a brass band heater is and discover its unique features and applications. Understanding Brass Band Heaters Brass band heaters are cylindrical heating elements that wrap around pipes, tubes, or cylinders. They provide uniform heat distribution across their surface and are prized for their excellent thermal conductivity and corrosion resistance. Key Components of a Brass Band Heater Heating Element: Usually a nickel-chromium wire Brass Sheath: Provides excellent heat transfer and corrosion resistance Insulation: Typically mica or ceramic fiber Terminals: For connecting to a power source Clamping Mechanism: Ensures tight fit around the target surface The brass construction of these heaters offers unique advantages. It allows for rapid heat transfer and uniform temperature distribution. How Brass Band Heaters Work The operation of a brass band heater is based on simple yet effective principles. When electrical current passes through the heating element, it generates heat, which is then transferred through the insulation to the brass sheath. Heat Transfer Process Electrical energy converts to heat in the resistance wire Heat transfers through the insulation to the brass sheath The brass sheath conducts heat to the target surface The efficiency of brass band heaters lies in their ability to provide even heating. This makes them ideal for applications requiring precise temperature control. Types of a Brass Band Heater Brass band heaters come in various types to suit different applications. Here are some common varieties: Standard Brass Band Heaters: General-purpose heaters for most applications High-Watt Density Brass Band Heaters: For applications requiring intense heat Nozzle Brass Band Heaters: Specifically designed for heating injection molding nozzles One-Piece Brass Band Heaters: Offer easy installation and removal Two-Piece Brass Band Heaters: Allow for installation without disconnecting the pipe or cylinder Advantages of Using Brass Band Heaters Brass band heaters offer several benefits that make them popular across industries: Excellent Heat Transfer: Brass conducts heat efficiently Uniform Heating: Provides even temperature distribution Corrosion Resistance: Brass resists corrosion better than many other metals Durability: Designed to withstand harsh industrial environments Versatility: Suitable for a wide range of applications Easy Installation: Can be easily clamped or bolted into place Energy Efficiency: Concentrates heat where it’s needed most Selecting the Right Brass Band Heater Choosing the appropriate brass band heater is crucial for optimal performance. Consider the following factors: Watt Density: Determine the heat output required Diameter and Width: Ensure proper fit on the target surface Voltage: Match the heater to your power supply Temperature Requirements: Consider maximum operating temperature Special Features: Such as built-in thermocouples or moisture resistance Environmental Factors: Consider any corrosive or abrasive conditions Consulting with a heating specialist can help you select the ideal brass band heater. They can provide guidance based on your specific application needs. Last Word A brass band heater represents a significant advancement in industrial heating technology. Its ability to provide uniform, efficient heating makes it indispensable in many industries. From plastic processing to food production, brass band heaters offer reliable and precise heating solutions. By understanding their principles and applications, you can fully realize the potential of these powerful heating elements.

The Manufacturing Process of Ceramic Heating Elements

A ceramic heating element, also known as ceramic radiant tube heater, is a type of heating element used in various industrial applications. They are designed to provide efficient and reliable heat transfer, making them a popular choice for many industries. The Manufacturing Process of Ceramic Heating Elements Raw Material Selection The manufacturing process of ceramic heating elements begins with selecting raw materials. Ceramic heating elements are typically made from ceramic powder, metal powder, and other additives. Mixing and Grinding The raw materials are then mixed and ground into a fine powder to ensure uniformity and consistency. Forming The powder mixture is then formed into the desired shape using various techniques such as extrusion, injection molding, or slip casting. Sintering The formed ceramic heating element is then sintered at high temperatures to bond the particles together and achieve the desired density. Coating A metal coating is applied to the ceramic heating element to enhance its thermal conductivity and electrical insulation properties. Assembly The ceramic heating element is then assembled into a heating element assembly, which includes a power source, a temperature control system, and other components. Testing and Quality Control The ceramic heating element is then tested for its thermal performance, electrical insulation, and mechanical strength to ensure it meets the required specifications. Types of Ceramic Heating Elements Ceramic Radiant Tube Heater A ceramic radiant tube heater is a type of ceramic heating element that uses a ceramic tube to emit infrared radiation. Ceramic Plate Heaters Ceramic plate heaters are a type of ceramic heating element that uses a ceramic plate to emit heat. Ceramic Strip Heaters Ceramic strip heaters are a type of ceramic heating element that uses a ceramic strip to emit heat. Applications of Ceramic Heating Elements Industrial Heating Ceramic heating elements are commonly used in industrial heating applications such as drying, curing, and annealing. Medical Equipment Ceramic heating elements are used in medical equipment such as surgical instruments, medical implants, and diagnostic devices. Aerospace Ceramic heating elements are used in aerospace applications such as satellite, aircraft, and spacecraft components. Benefits of Ceramic Heating Elements High-Temperature Resistance Ceramic heating elements can withstand extremely high temperatures, making them suitable for high-temperature applications. Corrosion Resistance Ceramic heating elements are corrosion-resistant, making them suitable for harsh environments. Low Maintenance Ceramic heating elements require minimal maintenance, making them a cost-effective option for many applications. Wrap Up In conclusion, the manufacturing process of ceramic heating elements involves several stages, from raw material selection to testing and quality control. Ceramic heating elements are used in various industrial applications and offer several benefits, including high-temperature resistance, corrosion resistance, and low maintenance. By understanding the manufacturing process and applications of ceramic heating elements, you can make informed decisions when selecting the right heating element for your specific needs.

Cartridge Heater For 3d Printer: A Comprehensive Guide

Are you tired of dealing with inconsistent temperature control in your 3D printing process? Do you struggle with hot-ends that take forever to heat up or cool down? Look no further! In this article, we’ll explore the benefits, types, and applications of cartridge heaters for 3D printers. What is a Cartridge Heater? A cartridge heater is a heating element designed specifically for 3D printing applications. It’s a self-contained unit that consists of a heating coil, insulation, and a thermally conductive material, all housed within a compact cartridge. This design allows for efficient heat transfer, precise temperature control, and fast heating and cooling times. Benefits of Cartridge Heaters for 3D Printers Improved Temperature Control Cartridge heaters offer superior temperature control compared to traditional heating elements. With a cartridge heater, you can achieve precise temperature settings and maintain them consistently throughout printing. Faster Heating and Cooling Times Cartridge heaters can heat up and cool down quickly, reducing printing time and increasing productivity. Increased Safety The self-contained design of cartridge heaters eliminates the risk of electrical shock and reduces the risk of fires. Compact Design Cartridge heaters are designed to be compact, making them ideal for use in 3D printers with limited space. Types of Cartridge Heaters for 3D Printers Resistance Wire Cartridge Heaters Resistance wire cartridge heaters generate heat using a resistive heating element. They’re suitable for applications that require high temperatures and are often used in extruders and hot-ends. Ceramic Cartridge Heaters Ceramic cartridge heaters generate heat using a ceramic heating element. They’re suitable for applications that require high temperatures and are often used in extruders and hot-ends. PTC (Positive Temperature Coefficient) Cartridge Heaters PTC cartridge heaters use a PTC heating element to generate heat. They’re suitable for applications that require precise temperature control and are often used in extruders and hot-ends. Applications of Cartridge Heaters for 3D Printers Extruders Cartridge heaters are commonly used in extruders to heat the filament to the optimal temperature for printing. Hotends Cartridge heaters are used in hot-ends to heat the nozzle to the optimal temperature for printing. Print Bed Cartridge heaters can heat the print bed to the optimal temperature for printing. Chamber Heating Cartridge heaters can heat the printing chamber to the optimal temperature for printing. How to Choose the Right Cartridge Heater for Your 3D Printer Consider the Temperature Range Choose a cartridge heater that can achieve the desired temperature range for your printing application. Consider the Power Consumption Choose a cartridge heater that consumes the right amount of power for your printing application. Consider the Size and Compatibility Choose a cartridge heater that fits your 3D printer’s hotend or extruder and is compatible with your printing software. Troubleshooting Common Issues with Cartridge Heaters for 3D Printers Overheating Check the temperature setting and adjust it accordingly. Ensure proper airflow and cooling around the cartridge heater. Underheating Check the power consumption and adjust it accordingly. Ensure proper insulation and thermal conductivity around the cartridge heater. Noise and Vibration Check the cartridge heater’s installation and ensure it’s properly secured. Check for any loose connections or worn-out components. Conclusion Cartridge heaters for 3D printers offer improved temperature control, faster heating and cooling times, increased safety, and compact design. By understanding the benefits, types, and applications of cartridge heaters, you can make an informed decision when choosing the right one for your 3D printing needs. Remember to consider the temperature range, power consumption, size, and compatibility when selecting a cartridge heater. With the right cartridge heater, you can achieve optimal printing results and take your 3D printing game to the next level.

Exploring the Benefits of High-Quality Mica Heat Proof Cables

Mica heat proof cables are renowned for their exceptional thermal and electrical insulation properties, making them a crucial component in a wide range of industrial and commercial applications. As a leading material in the manufacturing of high-performance cables, mica exhibits remarkable heat resistance and insulation capabilities, providing numerous benefits for various industries. In this article, we will delve into the crucial advantages of utilizing high-quality mica heat proof cables. Superior Heat Resistance and Insulation The standout feature of mica heat proof cables lies in their unparalleled ability to withstand high temperatures and maintain excellent insulation properties even in extreme operating conditions. Mica’s natural mineral composition, combined with its unique layered structure, confers exceptional resistance to heat, flames, and thermal stress. This makes mica heat proof cables ideal for applications that demand reliable performance in high-temperature environments, such as industrial furnaces, ovens, heaters, and other heating systems. Moreover, mica’s outstanding dielectric strength and insulating properties enable these cables to effectively withstand electrical stress, making them well-suited for use in electrical equipment and machinery operating at elevated temperatures. The inherent thermal stability of mica contributes to the long-term reliability and safety of electrical systems, providing peace of mind in critical applications where heat and electrical insulation are paramount. Mechanical Strength and Durability In addition to their exceptional thermal and electrical properties, high-quality mica heat proof cables offer impressive mechanical strength and durability. The incorporation of mica tape or mica paper within the cable’s construction provides reinforcement and protection against mechanical stresses, including vibrations, bending, and abrasion. This robustness ensures that the cables maintain their integrity and performance in demanding industrial environments, contributing to their longevity and reliability. The enhanced mechanical strength of mica heat proof cables also makes them suitable for use in applications where exposure to mechanical wear and tear is a primary concern, such as in heavy machinery, industrial equipment, and automotive systems. By combining superior heat resistance with robust mechanical performance, these cables offer a comprehensive solution for demanding operational requirements across various industrial sectors. Chemical and Corrosion Resistance Another significant benefit of high-quality mica heat proof cables is their resistance to chemicals and corrosion, further enhancing their suitability for harsh industrial environments. Mica’s non-reactive nature and inert characteristics make the cables impervious to the detrimental effects of corrosive agents, acids, and alkalis commonly encountered in chemical processing plants, petrochemical facilities, and offshore installations. This resistance enables the cables to maintain their structural and functional integrity in the presence of aggressive chemicals, providing dependable performance in critical industrial processes. The ability of mica heat proof cables to withstand chemical exposure extends their applicability to a broad spectrum of industries, including pharmaceutical manufacturing, food processing, and oil and gas production, where stringent regulatory compliance and operational reliability are essential. Conclusion High-quality mica heat proof cables represent a cornerstone in the realm of industrial and electrical insulation, offering unparalleled heat resistance, electrical insulation, mechanical durability, and chemical resistance for critical applications across diverse sectors. From high-temperature industrial processes to electrical machinery operating in demanding conditions, mica heat proof cables excel in providing the reliability and safety required in modern industrial environments. Given their exceptional performance characteristics, the utilization of high-quality mica heat proof cables is pivotal in ensuring operational efficiency, longevity, and safety across industries where exposure to extreme temperatures, electrical stress, and harsh chemicals is a constant factor. As a fundamental component in the construction of reliable electrical and thermal systems, mica heat proof cables continue to play a vital role in advancing industrial technology and enhancing the safety and performance of critical applications.

Top 3 Benefits of Installing Warm Floor Cables in Your Home

Warm floor cables, also known as electric underfloor heating systems, have become increasingly popular for homeowners seeking a comfortable and efficient heating solution. These innovative systems offer a range of benefits that go beyond traditional heating methods. In this article, we will explore the top 3 benefits of installing warm floor cables in your home. Enhanced Comfort and Wellness One of the most notable benefits of warm floor cables is the enhancement of comfort and overall well-being within your home. Unlike conventional forced-air heating systems, which may create temperature imbalances and drafts, warm floor cables provide a gentle and consistent heat distribution from the floor up. This radiant heat not only ensures warm and cozy living spaces but also promotes better air quality by minimizing the circulation of dust and allergens often associated with traditional heating methods. The soothing warmth beneath your feet creates a luxurious and comfortable environment, making the transition to cooler seasons a more enjoyable experience for you and your family. Energy Efficiency and Cost Savings Warm floor cables are recognized for their exceptional energy efficiency, offering a cost-effective heating solution that can lead to long-term savings. The even and consistent heat dispersion provided by these systems ensures that rooms are heated more effectively, allowing for lower overall thermostat settings. As a result, warm floor cables often contribute to reduced energy consumption and lower heating bills, providing homeowners with the dual benefit of cost savings and environmental sustainability. Furthermore, the ability of warm floor cables to retain heat even after being turned off means less energy is required to maintain comfortable temperatures, adding to their overall efficiency. In new construction or renovation projects, warm floor cables represent an investment in energy-efficient heating that can significantly contribute to the long-term value of a home. Versatility and Space Optimization Beyond the comfort and efficiency they offer, warm floor cables provide a versatile heating solution that maximizes space and design flexibility in your home. Unlike radiators or forced-air vents, warm floor cables are discreetly installed beneath the floor surface, eliminating the need for visible heating elements and freeing up valuable wall and floor space. This creates a more versatile and aesthetically pleasing living environment, allowing complete freedom in furniture placement, room layout, and interior design without the constraints of traditional heating appliances. Moreover, warm floor cables can be installed under a variety of floor coverings, including tile, wood, laminate, and even carpet, providing homeowners with the flexibility to incorporate radiant heating into virtually any room in the house. This versatility allows for a seamless integration of modern heating technology into both new construction projects and existing homes, without compromising on interior design or architectural features. Conclusion Warm floor cables offer enhanced comfort, energy efficiency, cost savings, and versatile design opportunities that make them a compelling choice for homeowners seeking a modern and effective heating solution. With the numerous benefits they provide, warm floor cables represent an innovative and practical approach to heating that can enhance the overall quality of life within your home.

Enhancing Industrial Operations with High-Quality Band Heaters from Cheri Heater Technology

In the fast-paced world of manufacturing, having efficient and reliable industrial heaters is crucial for maintaining optimal production processes. At Cheri Heater Technology Co., Ltd, we specialize in producing top-quality band heaters that cater to a wide range of industrial applications. As a leading manufacturer of industrial heating elements, we take pride in delivering heating solutions that are durable, efficient, and designed to meet the demanding requirements of modern industries. Unveiling Our Extensive Range of Band Heaters At Cheri Heater Technology Co., Ltd, we offer a diverse selection of band heaters designed to provide superior thermal performance and reliability. Our band heater product line includes: Brass Band Heater Ceramic Band Heater Mica Band Heater Each type of band heater is meticulously crafted using high-grade materials and cutting-edge manufacturing techniques to ensure optimal heat transfer, energy efficiency, and longevity. Whether you require precise temperature control, rapid heating capabilities, or corrosion resistance, our band heaters are engineered to meet your specific industrial heating needs. Quality and Certification You Can Trust Cheri Heater Technology Co., Ltd is an ISO 9001:2008 and CE certified company, demonstrating our commitment to upholding the highest quality standards in the manufacturing of industrial heaters. Our band heaters are manufactured using top-grade materials that undergo rigorous quality control processes to ensure consistent performance and durability. Customized Heating Solutions Tailored to Your Needs We understand that every industrial application is unique, which is why we offer tailor-made heating solutions crafted to precise shapes, sizes, and materials to meet your specific requirements. Our team of experienced engineers works closely with customers to design custom band heaters that align with their operational needs, ensuring maximum efficiency and performance. Unmatched Customer Support and Satisfaction At Cheri Heater Technology Co., Ltd, customer satisfaction is at the core of our business philosophy. From initial consultation to after-sales service, we provide unparalleled customer support to ensure that our clients’ heating needs are met with precision and excellence. Our robust warranty policies and responsive customer service team are dedicated to addressing any queries or concerns promptly and efficiently. Enhancing Efficiency and Cost-Effectiveness Our band heaters are designed to deliver optimal thermal performance with minimal energy consumption, enhancing cost-effectiveness and longevity for industrial operations. By choosing Cheri Heater band heaters, customers can experience improved efficiency, reduced downtime, and increased productivity in their manufacturing processes. Conclusion Cheri Heater Technology Co., Ltd stands as a trusted manufacturer of high-quality band heaters that are engineered to enhance industrial operations across various sectors. With a focus on quality, customization, and customer satisfaction, we are dedicated to providing innovative heating solutions that empower businesses to thrive in today’s competitive marketplace. Visit cheri-heater.com to explore our full range of industrial heaters and experience the difference that our band heaters can make in your manufacturing processes. Trusted by industry professionals worldwide, Cheri Heater band heaters are the epitome of excellence in industrial heating technology.

Top Features to Look for in the Best CO2 Heater Manufacturers

When searching for the best CO2 heater manufacturers, it is important to consider certain key features that can make a significant difference in the quality and reliability of the products. Here are some top features to look for when choosing a CO2 heater manufacturer: Reputation and Experience One of the first things to consider when looking for a CO2 heater manufacturer is their reputation and experience in the industry. A manufacturer with a strong reputation and years of experience is more likely to provide high-quality products and reliable service. Quality of Products The quality of the CO2 heaters produced by a manufacturer is crucial. Look for manufacturers who use high-quality materials and adhere to strict manufacturing standards to ensure that their products are durable, efficient, and safe to use. Energy Efficiency In a time where energy efficiency is a top priority, choosing a CO2 heater manufacturer that prioritizes energy efficiency in their products can help you save on energy costs in the long run. Look for manufacturers who design their heaters to be energy-efficient and environmentally friendly. Safety Features Safety should be a top priority when it comes to choosing a CO2 heater manufacturer. Look for manufacturers who incorporate advanced safety features in their heaters, such as automatic shut-off mechanisms and overheat protection, to ensure the safety of you and your family. Customization Options If you have specific requirements for your CO2 heater, such as size, heating capacity, or design, look for manufacturers who offer customization options. Choosing a manufacturer that can customize their products to meet your specific needs can ensure that you get the perfect heater for your space. Certifications and Compliance Ensure that the CO2 heater manufacturer you choose has the necessary certifications and complies with industry standards and regulations. This can give you peace of mind knowing that their products meet the required safety and quality standards. Conclusion When looking for the best CO2 heater manufacturers, consider factors such as reputation, product quality, energy efficiency, safety features, warranty, customization options, certifications, and customer reviews. By paying attention to these key features, you can make an informed decision and choose a manufacturer that delivers high-quality CO2 heaters that meet your needs and expectations.

Choosing the Right Mica Heat Proof Cable Manufacturer: Key Factors to Consider

When it comes to high-temperature applications, selecting the right mica heat proof cable manufacturer is crucial for ensuring safety, reliability, and efficiency. With numerous options available in the market, it can be challenging to make the best choice. In this blog post, we will discuss the key factors to consider when choosing a mica heat proof cable manufacturer to meet your specific needs. Quality and Standards The quality of mica heat proof cables directly impacts their performance and longevity. Ensure the manufacturer adheres to industry standards and certifications such as ISO, UL, or CE. These certifications indicate that the manufacturer follows strict quality control measures and produces reliable products. Experience and Expertise A manufacturer with extensive experience and expertise in producing mica heat proof cables is more likely to provide high-quality products and services. Look for companies with a proven track record and positive customer reviews. Experienced manufacturers are also better equipped to handle custom requirements and provide technical support. Product Range and Customization Different applications may require specific types of mica heat proof cables. Choose a manufacturer that offers a wide range of products to meet various needs. Additionally, consider whether the manufacturer can customize cables to your exact specifications, including size, length, and insulation properties. Technological Advancements Innovation is key to improving the performance and durability of mica heat proof cables. Select a manufacturer that invests in research and development to stay ahead of industry trends. Cutting-edge technology and materials can enhance the efficiency and safety of the cables. Customer Support and Service Excellent customer support is essential for a smooth purchasing experience and ongoing satisfaction. Choose a manufacturer known for responsive and knowledgeable customer service. They should be able to provide technical assistance, answer questions, and resolve any issues promptly. Pricing and Value for Money While cost is an important factor, it should not be the sole determinant. Compare prices from different manufacturers, but also consider the overall value for money. High-quality mica heat proof cables may have a higher upfront cost but can save money in the long run by reducing maintenance and replacement needs. Delivery and Logistics Timely delivery is crucial, especially for large projects with strict deadlines. Ensure the manufacturer has a reliable logistics network and can deliver products within the required timeframe. Check their delivery policies, lead times, and shipping options to avoid any delays. Conclusion Choosing the right mica heat proof cable manufacturer requires careful consideration of various factors, including quality, experience, product range, technological advancements, customer support, pricing, and delivery capabilities. By taking these factors into account, you can make an informed decision and select a manufacturer that meets your specific requirements.

How to Choose the Best Heating Cable for Your Needs

Are you in the market for a heating cable but not sure where to start? With so many options available from various manufacturers, it can be overwhelming to choose the right one for your specific needs. To help you make an informed decision, here are some essential factors to consider when selecting the best heating cable for your requirements. Determine Your Heating Needs The first step in choosing a heating cable is to identify your heating requirements. Consider factors such as the area you need to heat, the temperature range needed, and the type of surface where the cable will be installed. By determining your specific heating needs, you can narrow down the options and select a heating cable that meets your requirements. Quality and Reliability When looking for heating cable manufacturers, prioritize quality and reliability. Look for reputable manufacturers like Cheri Heater who have a proven track record of producing high-quality heating cables. Check for certifications and standards compliance to ensure that the heating cable meets industry regulations and safety standards. Type of Heating Cable There are different types of heating cables available, including self-regulating cables, constant wattage cables, and mineral insulated cables. Each type has unique characteristics and applications. Self-regulating cables adjust their heat output based on the temperature, making them energy-efficient. Constant wattage cables provide a uniform heat output, while mineral insulated cables are durable and suitable for high-temperature applications. Choose the type of heating cable that best suits your heating needs. Installation and Maintenance Consider the installation requirements and maintenance of the heating cable. Some heating cables are designed for easy installation and minimal maintenance, while others may require professional installation and regular upkeep. Choose a heating cable that is easy to install and maintain to ensure optimal performance and longevity. Energy Efficiency Opt for energy-efficient heating cables that can help reduce energy consumption and lower heating costs. Look for heating cables with advanced features such as temperature control, insulation, and energy-saving modes. Energy-efficient heating cables not only save you money but also contribute to a more sustainable and environmentally friendly heating solution. Warranty and Support Before making a purchase, inquire about the warranty and support provided by the heating cable manufacturer. A reliable warranty ensures that your investment is protected, and you can receive assistance in case of any issues or malfunctions. Choose a manufacturer that offers a comprehensive warranty and reliable customer support to address any concerns or inquiries. Conclusion Selecting the best heating cable for your needs involves careful consideration of factors such as your heating requirements, quality and reliability, type of heating cable, installation and maintenance, energy efficiency, and warranty and support. By choosing a reputable manufacturer like Cheri Heater and evaluating these key factors, you can make an informed decision and ensure that you have the best heating cable for your specific needs.