How to Improve Temperature Accuracy in Small-Scale Manufacturing

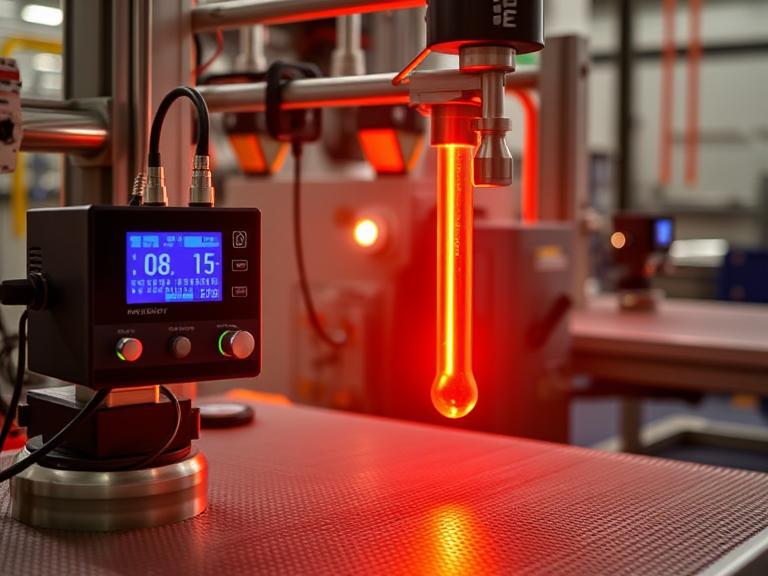

In today’s rapidly evolving industrial landscape, efficiency and control are the backbone of every high-performing system. Whether it’s plastic molding, packaging, laboratory experiments, or food processing, accurate temperature management plays a crucial role in ensuring consistent output, energy savings, and operational safety. At Cheriheater, we understand how even the smallest improvement in thermal performance can drive major gains. That’s why we focus on reliable heating technologies built for demanding environments. In this blog post, we’ll take a deeper look into how modern heating components can streamline processes, improve product quality, and reduce energy waste, plus how to choose the right tools for the job. The Challenge of Industrial Heating Heating systems are the lifeblood of many industries. From maintaining molten plastic in an injection molding machine to sealing food packages or sterilizing equipment, heat is a required force. But here’s the challenge: inconsistent heating leads to uneven results. Imagine trying to mold plastic with fluctuating temperatures—you’d end up with warped or defective parts. Or think about lab testing where even a few degrees off can distort your entire dataset. It’s not just about heat; it’s about controlled, precise, reliable heat. Why Precision Heating Is Non-Negotiable 1. Minimizes Waste Consistent heat ensures uniformity. That means fewer rejected products and more efficient production cycles. 2. Protects Equipment When components are not overheated or exposed to thermal shock, their life expectancy increases significantly. 3. Improves Energy Efficiency Controlled heating eliminates unnecessary power usage. Less energy wasted equals more money saved. 4. Enhances Safety Overheating or erratic temperature swings can lead to system failures or even fire hazards. With the right equipment, these risks are minimized. Key Features to Look for in a Heating Solution Choosing the right heating component is not just about wattage or size—it’s about compatibility with your system and control over performance. Here are the top features to look out for: ● Rapid Heat-Up Time You want a heater that can reach operating temperature quickly without overshooting. ● Uniform Heat Distribution The element should provide even heating throughout the surface area to prevent hot spots. ● Compact Design In many cases, space is limited. A heating element should be powerful, yet compact enough to fit within tight setups. ● Integrated Sensing Advanced models include built-in temperature sensing components for real-time monitoring. Meet the Unsung Hero: Cartridge Heaters Cartridge heaters are cylindrical heating elements designed to be inserted into holes drilled in metal blocks. These heaters offer an excellent solution for localized heating and are widely used in dies, molds, platens, and packaging machinery. They are valued for: High watt density Efficient heat transfer Tight fit installation Long service life Many industries rely on these compact units to maintain heat directly where it’s needed, reducing energy loss and improving response time. Precision Gets an Upgrade: Thermocouples To go a step further, thermocouples are added to heating systems to monitor temperature in real time. These tiny devices generate a voltage signal based on the temperature difference between two dissimilar metals, making them highly accurate and responsive. Pairing a heater with a thermocouple is like adding a speedometer to a car—it doesn’t change how the car works, but it ensures you know exactly how it’s performing. For example, if you’re operating a precision-driven process like seal bar heating in packaging, you don’t want guesswork—you want exact numbers, consistent performance, and fast adjustments when needed. This is where a cartridge heater with thermocouple becomes incredibly effective, combining compact power with intelligent feedback in one integrated solution. Common Applications Here are just a few of the places where precision heating matters—and where solutions like cartridge heaters shine: Plastic Injection Molding Packaging & Sealing Machines Laboratory Instruments 3D Printing Platforms Food Processing Units Medical & Sterilization Equipment Each of these applications requires consistent, controlled heating within tight tolerances. That’s where engineered components make all the difference. Tips for Choosing the Right Heating Element If you’re planning to upgrade your heating setup or start from scratch, keep these practical tips in mind: 1. Know Your Operating Temperature Different applications call for different heat levels. Ensure the element is rated for your target range. 2. Measure Installation Area Precisely Cartridge heaters are typically press-fitted, so accurate sizing is essential. 3. Factor in Heat Loss Think about where heat might escape in your system—choose a heater that compensates accordingly. 4. Consider Lead Wire Configuration Lead wires should match the environmental and mechanical conditions of your setup. Why Choose Cheriheater? At Cheriheater, we’re more than just a heating element supplier—we’re your partner in precision heating. We manufacture and customize heaters that are trusted in applications around the world, with performance, safety, and durability at the core of every product. Our team is ready to help you select the right solution, whether it’s off-the-shelf or built to spec. From consultation to after-sales support, we’re committed to quality you can count on. Final Thoughts Precision heating is not a luxury—it’s a requirement in today’s industrial world. With the right tools in place, you can improve performance, ensure consistency, and protect your systems from unnecessary wear and tear. The combination of a smart design, reliable components, and responsive support can transform how your systems operate—and boost your bottom line.

How to Choose the Right Heating Solution for Your Manufacturing Needs

In the world of manufacturing, precision, efficiency, and consistency are essential. Whether you’re working with plastics, metals, chemicals, or food processing, heating systems are at the core of your operations. Choosing the right heating solution can significantly impact your productivity, energy consumption, and product quality. With so many technologies available—from cartridge heaters to infrared panels—how do you determine which one is right for your specific manufacturing needs? At Cheriheater, we specialize in helping manufacturers make informed decisions when it comes to industrial heating solutions. In this guide, we’ll walk you through the key factors to consider when choosing the most effective heating solution for your operation. 1. Understand Your Application Requirements The first step in choosing a heating solution is to thoroughly understand your application’s unique requirements. Every manufacturing process is different and demands specific parameters when it comes to: Temperature range: Some applications require precise, low-temperature control, while others may demand high heat. Heat-up time: Do you need rapid heat-up or is gradual warming acceptable? Material compatibility: Will the heater be in direct contact with your product or surrounding machinery? Environmental conditions: Is your process exposed to moisture, dust, or corrosive chemicals? Clearly identifying these requirements will help you narrow down which heating technologies are most suitable. 2. Evaluate the Type of Heater Needed There are several types of industrial heaters, each with unique benefits and ideal use cases. Some of the most common include: Cartridge Heaters These are compact, cylindrical heaters often used to heat metal blocks, molds, or tools. They offer high watt density and precise temperature control, making them ideal for applications like plastic molding or packaging machinery. Band Heaters Typically used to heat cylindrical surfaces such as pipes, nozzles, or drums. Band heaters are great for injection molding and extrusion equipment. Tubular Heaters These are versatile heaters that can be shaped into various configurations. Ideal for heating air, gases, and liquids, tubular heaters are often used in ovens, immersion tanks, and ducts. Infrared Heaters Perfect for non-contact heating, these are often used in curing, drying, and coating processes. Infrared heaters can offer energy savings and faster response times. Immersion Heaters Used for directly heating liquids, immersion heaters are common in chemical processing, water treatment, and oil heating applications. Matching the heater type to your process needs will ensure efficiency and longer operational life. 3. Assess Power Requirements and Energy Efficiency Another critical factor is the power requirement. How much wattage do you need to achieve and maintain your desired temperature? Choosing a heater with the correct watt density (watts per square inch) is vital to prevent overheating or underperformance. In today’s energy-conscious environment, energy efficiency is more important than ever. Look for heating solutions that offer: Uniform heat distribution Fast response times Integrated temperature sensors or controllers Minimal heat loss to the environment Using advanced controls and sensors not only boosts efficiency but also enhances safety and reduces operating costs. 4. Consider the Control Systems A heating system is only as effective as its controls. Precision in temperature regulation is crucial for many industrial processes. Depending on your process, you might need: Basic thermostats Digital controllers with programmable settings PLC (Programmable Logic Controller) integration for complex automation Choosing the right control system helps maintain consistent temperature levels, reduces waste, and improves product quality. 5. Think About Installation and Maintenance Ease of installation and maintenance are often overlooked but can have long-term cost implications. When choosing a heating solution, ask the following: Is it easy to integrate with existing equipment? Are replacement parts readily available? What is the expected lifespan? Is maintenance frequent or minimal? Opting for heaters that are modular or easy to replace can reduce downtime during maintenance or unexpected failures. 6. Safety and Compliance Standards Industrial heating systems must comply with safety and regulatory standards. Make sure the heater and its components are: Certified by relevant bodies (e.g., CE, UL, RoHS) Designed with built-in safety mechanisms like thermal cutoffs or overload protection Made with materials that suit your industry’s compliance requirements (e.g., food-grade stainless steel) Safety should never be compromised, especially when working in high-temperature or hazardous environments. 7. Work with a Reliable Supplier or Manufacturer One of the most important decisions is choosing who to partner with. A trustworthy heating element manufacturer can provide tailored solutions, expert advice, and after-sales support. Customization is often key in manufacturing, and working with an experienced manufacturer ensures your heating system is designed to your exact specifications. Look for a supplier with a solid track record, client testimonials, and the ability to design, prototype, and produce heaters in-house. This ensures quality control, fast lead times, and scalable production. 8. Factor in Budget vs. Long-Term ROI While initial cost is a key consideration, it’s equally important to evaluate long-term return on investment (ROI). A cheaper heater may save money upfront but could lead to higher energy bills, frequent repairs, or poor process control. Instead, weigh the total cost of ownership: Initial purchase price Installation and integration costs Operating and energy costs Maintenance and downtime Lifespan and reliability Choosing the right heating solution can result in higher productivity, lower energy bills, and fewer equipment failures—making it a smart long-term investment. Conclusion: Selecting the right heating solution for your manufacturing process involves a careful evaluation of technical requirements, energy efficiency, safety, and vendor reliability. By following a structured decision-making process and consulting with experts, you can ensure that your heating system delivers optimal performance and value. At Cheriheater, we pride ourselves on offering high-quality, custom-designed heating solutions for a wide range of industrial applications. Whether you’re in plastics, packaging, chemicals, or food production, we’re here to help you choose the best heating technology for your unique needs. If you’re looking to optimize your heating process, improve energy efficiency, and enhance product quality, contact our team today to discuss your project requirements.

Different Types of Heaters for Industrial Applications

In industrial settings, heating solutions are crucial to ensuring smooth and efficient operations. Whether it’s for manufacturing, food processing, or other industrial processes, selecting the right type of heater can have a major impact on productivity and energy efficiency. With a wide range of options available, businesses must choose the best solution based on their specific needs. In this post, we will explore the various types of industrial heaters, discuss their benefits, and provide guidance on how to choose the best heater for your industrial application. 1. Electric Heaters: Versatile and Efficient Electric heaters are widely used in industrial applications due to their efficiency and precision. They convert electrical energy into heat, making them ideal for controlled environments where temperature regulation is critical. Types of Electric Heaters: Cartridge Heaters: One of the most common forms of electric heaters, cartridge heaters are compact, cylindrical heating elements that are often used in molds, tanks, and machinery requiring concentrated heat. These heaters are known for their high thermal efficiency and ease of integration into industrial systems. They are ideal when you need space-efficient solutions with precise heating control. Band Heaters: These heaters wrap around cylindrical surfaces, such as pipes or barrels, to provide even heat distribution. Commonly used in extrusion processes, they are ideal for operations where uniform heating is required. Why Choose Electric Heaters? Precise Control: Electric heaters, such as cartridge heaters, offer exceptional control, allowing for accurate temperature adjustments that are essential for many industrial processes. Energy Efficiency: They can heat spaces quickly without waste, making them a great choice for businesses aiming to minimize energy costs. Low Maintenance: Electric heaters typically require less maintenance compared to gas-powered models, contributing to lower operational costs. Electric heating solutions are ideal for companies that need reliable and easy-to-maintain heating systems for small or medium-sized applications. 2. Gas Heaters: Cost-Effective for Larger Spaces Gas heaters are commonly used in large industrial spaces where high heat output is necessary. They work by burning natural gas or propane to generate heat, making them more cost-effective for operations that need a significant amount of heat for large areas. Advantages of Gas Heaters: Lower Operating Costs: Gas-powered heaters tend to have lower operating costs when compared to electric heaters, especially for large-scale applications. High Heat Output: Gas heaters can produce a large amount of heat in a relatively short amount of time, making them ideal for large warehouses or production facilities. Versatility: They can be used in both indoor and outdoor applications, though proper ventilation is necessary for indoor use to avoid the accumulation of dangerous gases. While gas heaters are great for large spaces, they do require careful safety management and ongoing maintenance to ensure they function safely and efficiently. 3. Infrared Heaters: Ideal for Spot Heating Infrared heaters provide a unique heating solution by emitting infrared radiation to directly heat objects and surfaces, rather than heating the air around them. This makes infrared heaters especially useful for applications that require localized heating or when traditional convection heating would be inefficient. How Infrared Heaters Work: Infrared heaters emit radiation that directly heats objects in their line of sight. Unlike conventional heating systems that heat the air and rely on convection to spread warmth, infrared heaters focus on the target object, providing rapid heating with minimal energy waste. Applications of Infrared Heaters: Drying and Curing: Infrared heaters are widely used in industries like automotive and manufacturing for drying paint or curing materials. Food Processing: In food production, infrared heating is used for drying or cooking food products quickly and evenly. Why Use Infrared Heaters? Energy Efficient: Infrared heaters provide targeted heating, minimizing energy loss and increasing efficiency. Rapid Heating: Infrared heaters can heat objects almost instantly, reducing waiting times in high-speed production processes. Minimal Air Movement: Infrared heaters are ideal for processes that require minimal air movement, such as in cleanrooms or laboratory settings. Infrared heaters are an excellent option for industries that require quick and efficient spot heating in specific areas. 4. Immersion Heaters: Effective Heating for Liquids Immersion heaters are designed for heating liquids directly within tanks or other containers. This type of heater is commonly used in industries such as chemical processing, food production, and pharmaceuticals, where precise liquid heating is essential. How Immersion Heaters Work: Immersion heaters are placed directly into the liquid that needs to be heated. This direct contact between the heating element and the liquid ensures uniform and efficient heating. Advantages of Immersion Heaters: Direct Heating: Since the heater is submerged in the liquid, it directly heats the fluid, which leads to more efficient heating compared to external heating methods. Cost-Effective: Immersion heaters are often more affordable than other heating systems, making them a popular choice for many businesses. Versatility: They can be used to heat a wide variety of liquids, including water, oils, and chemicals. Immersion heaters are ideal for any industrial application that requires the heating of liquids, such as tanks or vats. 5. Choosing the Right Heater: Key Considerations When selecting the right heating solution for your industrial application, several key factors should be considered to ensure that the system you choose meets your operational needs effectively: 1. Space and Heating Area: For small, localized heating, cartridge heaters are an excellent choice, as they offer high efficiency in tight spaces. Larger spaces or areas requiring significant heat output may be better suited to gas heaters or infrared heating systems. 2. Energy Efficiency: If energy efficiency is a top priority, electric heaters, especially cartridge heaters, provide excellent performance with minimal waste. 3. Temperature Control Requirements: Electric heaters with precise temperature control are ideal for applications requiring constant, reliable heat, such as those in the manufacturing or pharmaceutical industries. 4. Maintenance and Safety: Electric heaters like cartridge heaters tend to require less maintenance than gas heaters. Consider the level of ongoing maintenance your business can handle when making a choice. 5. Application Type: For heating liquids, immersion heaters are the go-to solution. For large areas, gas or infrared heaters

Top Applications of Micro Cartridge Heaters in Modern Industry

Micro cartridge heaters are compact, high-performance heating elements used in a wide range of modern industrial applications. Designed for precision, reliability, and efficiency, these small heaters deliver concentrated heat exactly where it’s needed. Their versatility and robust construction make them essential components across many industries. Here’s a closer look at the top applications of micro cartridge heaters today: 1. Medical Equipment In the medical field, precision and consistency are crucial. Micro cartridge heaters are widely used in devices such as blood analyzers, diagnostic equipment, and surgical instruments. Their ability to maintain exact temperatures helps ensure accurate test results and improves patient safety. Additionally, these heaters are ideal for fluid warming applications, helping maintain critical temperatures for IV fluids and surgical irrigation. 2. Plastic Injection Molding Plastic manufacturing heavily relies on micro cartridge heaters, especially for mould heating. They provide fast, even heat to small, confined spaces within molds, ensuring optimal material flow and product quality. Their compact design allows them to fit perfectly into mold cavities, improving cycle times and reducing production costs. 3. Aerospace Industry Aerospace technology demands high precision under extreme conditions. Micro cartridge heaters are used in de-icing systems, fluid delivery systems, and instrumentation. They help maintain stable temperatures for critical sensors and valves, ensuring aircraft performance and safety in various environments. 4. Packaging Machinery Modern packaging machines require consistent, controllable heat for processes such as sealing, cutting, and forming. Micro cartridge heaters are ideal for heating sealing bars, nozzles, and other small areas in packaging equipment. Their quick heating capabilities improve operational efficiency and ensure high-quality packaging results. 5. Semiconductor Manufacturing Semiconductor production involves extremely delicate processes that require clean, controlled environments. Micro cartridge heaters are used to heat chambers, wafers, and gas delivery systems. Their high precision and clean operation ensure minimal contamination, which is critical for producing high-quality semiconductor components. 6. Food and Beverage Processing Maintaining specific temperatures is vital in food and beverage processing for product quality and safety. Micro cartridge heaters are commonly used in coffee machines, food packaging equipment, and filling machines. Their fast response times and reliability help manufacturers meet strict hygiene and performance standards. 7. 3D Printing Additive manufacturing, particularly 3D printing, benefits greatly from micro cartridge heaters. These heaters maintain the correct temperature of the printer’s nozzle and build platform, ensuring smooth material extrusion and strong layer adhesion. As 3D printing technology evolves, the demand for precise, efficient heating solutions like micro cartridge heaters continues to grow. 8. Die-Casting In die-casting processes, maintaining consistent mold temperatures is essential to achieving high-quality metal parts. Micro cartridge heaters provide the necessary heat control in die-casting molds, reducing defects such as porosity and improving the structural integrity of the final product. Conclusion Micro cartridge heaters have become indispensable across various industries due to their precision, reliability, and adaptability. From medical devices to aerospace systems, their role in improving efficiency, safety, and product quality cannot be overstated. As industries continue to innovate, the applications of micro cartridge heaters are expected to expand even further, making them a cornerstone of modern manufacturing technology.

Cartridge Heater Manufacturer High-Performance Heating Solutions

Premium Cartridge Heaters for Industrial Applications Cartridge heaters are essential for precision heating. They provide efficient, high-temperature performance for various industries. Manufacturers design them for durability, ensuring consistent heat transfer. Why Choose a Reliable Cartridge Heater Manufacturer? A trusted manufacturer ensures quality and longevity. Their heaters meet strict industry standards. They use advanced materials for superior thermal conductivity. Each unit undergoes rigorous testing before shipment. Types of Cartridge Heaters High-Watt Density Cartridge Heaters These heaters deliver intense heat in compact spaces. They are ideal for applications requiring rapid heating. Low-Watt Density Cartridge Heaters Designed for even heat distribution, these heaters prevent material degradation. They work well in temperature-sensitive applications. Custom Cartridge Heaters Manufacturers offer tailored solutions. Custom heaters fit specific designs and dimensions, ensuring optimal performance. Key Features of High-Quality Cartridge Heaters High-Temperature Resistance: Withstands extreme heat without failure. Efficient Heat Transfer: Ensures uniform temperature distribution. Durable Construction: Built with corrosion-resistant materials. Easy Installation: Designed for a secure and seamless fit. Applications of Cartridge Heaters Cartridge heaters are used across multiple industries: Plastic Molding: Ensures precise temperature control. Medical Equipment: Provides accurate heating for sterilization. Food Processing: Maintains consistent temperatures for production. Automotive Industry: Supports critical manufacturing processes. How to Select the Best Cartridge Heater Manufacturer Choosing the right manufacturer is crucial. Consider these factors: Experience: Look for years of expertise in heating solutions. Material Quality: High-grade components ensure reliability. Customization Options: A good manufacturer provides tailored solutions. Customer Support: Responsive service ensures a smooth experience. Conclusion A professional cartridge heater manufacturer delivers top-quality, efficient, and durable heating solutions. Choose wisely to enhance your industrial processes. Would you like assistance in selecting the right cartridge heater for your needs? Contact a trusted manufacturer today!

What Are Finned Cartridge Heater Uses?

A finned cartridge heaters is a versatile and efficient heating solution widely used across various industries. They deliver reliable heat while ensuring durability and energy efficiency. These heaters stand out due to their high performance and adaptability, making them essential for numerous applications. Understanding their uses can help industries improve processes, save energy, and enhance product quality. Here, we explore the practical uses of finned cartridge heater in detail. Understanding Finned Cartridge Heater A finned cartridge heater is a tubular heating device with metal fins attached to its surface. These fins increase the surface area for heat transfer, improving thermal efficiency. The heater’s core is made of a resistance wire wrapped around a ceramic core, encased in a stainless steel sheath for durability. Key Features of Finned Cartridge Heater Finned cartridge heaters offer several benefits: Efficient Heat Transfer: Fins enhance heat dissipation, making the heater effective even in high-demand environments. Durability: The stainless steel sheath resists corrosion, ensuring a longer lifespan. Customizable Sizes: Heaters are available in various lengths, diameters, and wattages to fit specific applications. Energy Efficiency: Optimized design reduces energy consumption. Common Applications of Finned Cartridge Heater Finned cartridge heaters find applications in a wide range of industries. Below are some of their primary uses: 1. Plastic Industry Plastic processing often requires precise heating. Finned cartridge heaters help in: Injection Molding: Heating molds to maintain consistent material flow. Extrusion Machines: Ensuring the smooth melting of plastic granules. Hot Runner Systems: Providing localized heating for high-quality plastic components. 2. Food and Beverage Industry Temperature control is critical for food safety and quality. Finned cartridge heaters are used in: Packaging Machines: Sealing food packages securely with controlled heat. Ovens and Grills: Maintaining consistent cooking temperatures. Beverage Dispensing Systems: Heating liquids like coffee or tea to ideal serving temperatures. 3. Medical Equipment The healthcare industry relies on accurate and reliable heating solutions. These heaters are crucial for: Sterilization Units: Maintaining high temperatures for equipment sterilization. Diagnostic Machines: Providing necessary heat for accurate test results. Blood Analyzers: Ensuring stable temperature conditions. 4. Automotive Sector In the automotive industry, finned cartridge heaters help in processes such as: Engine Preheating: Keeping engines at optimal temperatures in cold climates. Mold Heating: Producing high-quality parts for vehicles. Seat Heating Systems: Enhancing passenger comfort. 5. Packaging Industry For efficient and high-speed operations, these heaters are used in: Shrink Wrapping Machines: Providing consistent heat for wrapping products. Heat Sealers: Sealing plastic bags and films. Labeling Equipment: Applying heat-sensitive labels to containers. How Finned Cartridge Heaters Work in Real Applications To better understand their efficiency, consider this example: Factors to Consider When Choosing Finned Cartridge Heaters When selecting a finned cartridge heater, keep these factors in mind: Size and Wattage: Choose based on the specific heating requirements of your application. Material: Stainless steel is ideal for durability and corrosion resistance. Temperature Range: Ensure the heater can achieve the necessary operating temperature. Mounting Options: Opt for easy installation to minimize downtime. Maintenance Tips for Longevityof a Cartridge Heater Proper maintenance ensures the heater’s long life and consistent performance: Regular Cleaning: Remove dust and debris from fins for effective heat dissipation. Inspect Connections: Check wiring and terminals for wear or damage. Avoid Overheating: Use a temperature controller to prevent excessive heat. Periodic Testing: Test heater performance to detect issues early. Final Words A finned cartridge heater is vital for various industries, offering reliable and efficient heating solutions. From plastic molding to food packaging and medical equipment, their uses are vast and impactful. Choosing the right heater and maintaining it properly ensures long-term benefits, improved productivity, and reduced energy costs. When you need consistent, efficient heat for critical applications, finned cartridge heaters are a dependable choice.

What Material is Used for Thread Cartridge Heaters

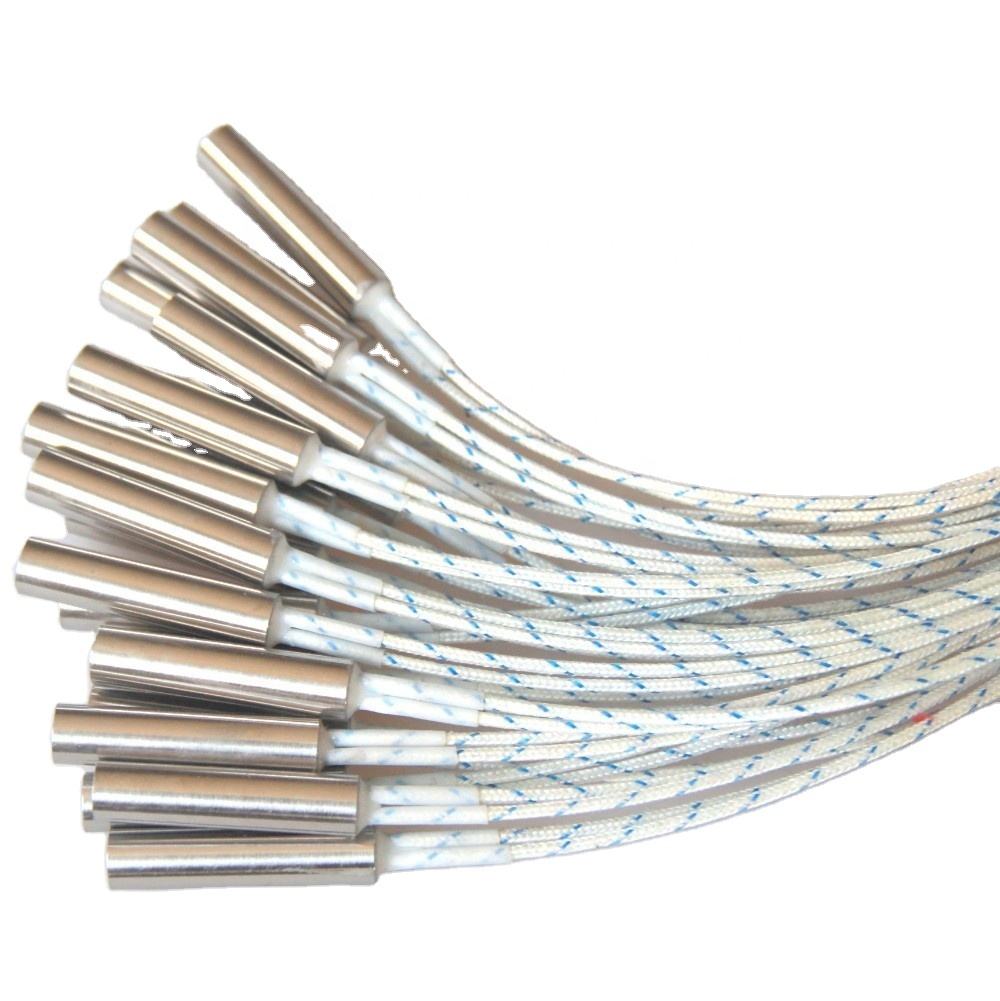

Thread cartridge heaters are essential in industries requiring precise and efficient heating. These heaters are cylindrical devices designed to transfer heat effectively. But have you ever wondered what materials make them so reliable and durable? This blog will explore the key materials used in thread cartridge heaters, why they are chosen, and how they enhance performance. Understanding Thread Cartridge Heaters Thread cartridge heaters are compact, high-temperature heating elements. They are often used in molds, dies, medical devices, and packaging equipment. The materials used in their construction play a significant role in ensuring their functionality. Each component is carefully designed to withstand harsh conditions, maintain efficiency, and ensure safety. Core Materials in Thread Cartridge Heaters Several materials are used to manufacture these heaters. Each serves a unique purpose and contributes to the heater’s durability and performance. 1. Sheath Material The sheath is the outermost layer of the heater. It protects internal components and ensures heat transfer. Common materials include: Stainless Steel: Known for corrosion resistance, it works well in high-temperature and moisture-prone environments. Incoloy: A nickel-based alloy, it offers excellent resistance to oxidation and scaling in extreme heat. Copper: Often used when rapid heat transfer is required. 2. Heating Element The heating element inside the cartridge generates heat. Typical materials include: Nickel-Chromium (Ni-Cr) Wire: Offers high electrical resistance and can withstand high temperatures. Kanthal Wire: Made from iron-chromium-aluminum, it provides exceptional longevity at elevated temperatures. 3. Insulation Material Insulation ensures the heat stays concentrated within the heater. Common materials are: Magnesium Oxide (MgO): This powder or compacted form has high thermal conductivity and electrical insulation properties. Ceramic Insulation: Used for extra durability and resistance to electrical breakdown. 4. Lead Wire Materials Lead wires connect the heater to the power source. They must withstand both heat and mechanical stress. Silicone-Insulated Wires: Ideal for flexibility and temperature resistance. Fiberglass-Insulated Wires: Used in high-temperature applications due to their excellent thermal resistance. Why These Materials Are Chosen Each material is selected based on specific properties that enhance the cartridge heater’s performance: High Thermal Conductivity: Ensures efficient heat transfer to the target application. Corrosion Resistance: Protects against harsh environments, extending heater life. Electrical Insulation: Prevents short circuits and ensures user safety. Mechanical Strength: Withstands vibrations and physical stress without damage. Key Benefits of Using the Right Materials Using the correct materials in threaded cartridge heaters ensures several advantages: Enhanced Efficiency: Proper materials ensure minimal heat loss and faster heating. Extended Lifespan: Durable materials resist wear and tear, even under tough conditions. Improved Safety: High-quality insulation materials prevent electrical hazards. Applications of Thread Cartridge Heaters Thread cartridge heaters are widely used across industries. Here are some common applications: Plastic Injection Molding: Heating molds to specific temperatures. Medical Equipment: Precise heating for sterilization or fluid control. Food Processing: Maintaining temperatures in packaging and sealing machines. Automotive Industry: Supporting heating systems for dies and molds. Wrap Up Thread cartridge heaters rely on carefully selected materials to deliver consistent performance in demanding environments. The combination of stainless steel sheaths, nickel-chromium elements, magnesium oxide insulation, and durable lead wires ensures these heaters are efficient, durable, and safe. When choosing or maintaining a thread cartridge heater, understanding the materials used can help you make informed decisions for your application.

What is Cartridge Heater With Thermocouple – A Short Guide

Cartridge heaters with thermocouples are essential tools in many industries. They combine heating elements with temperature sensors for precision. These heaters are designed to deliver localized heat and maintain accurate temperature control in various applications. If you’re working in manufacturing, engineering, or electronics, understanding these heaters can make a big difference in achieving efficient operations. This short guide will explain what they are, how they work, and where they are commonly used. What is a Cartridge Heater With Thermocouple? A cartridge heater is a cylindrical heating element. It generates heat by passing electricity through a resistive wire inside a metal casing. The addition of a thermocouple allows real-time temperature monitoring. The thermocouple is a built-in sensor that measures the heater’s temperature. This feature ensures consistent and controlled heating in critical processes. Cartridge heaters are available in various sizes, wattages, and materials. They are widely used in processes where precision heating is essential, such as plastic molding, food equipment, and medical devices. How Does a Cartridge Heater With Thermocouple Work? These heaters work on the principle of resistance heating. The resistive wire heats up when an electric current flows through it. The heat is transferred to the surrounding area via the metal sheath. The thermocouple plays a key role in temperature control. It measures the temperature at a specific point and sends the data to a controller. If the temperature exceeds or drops below the set range, the controller adjusts the power supply to maintain stability. Key Components of a Cartridge Heater With Thermocouple: Heating Element: Usually made of nickel-chromium (NiCr) wire for high efficiency. Metal Sheath: Protects the internal components and ensures efficient heat transfer. Common materials include stainless steel and Incoloy. Thermocouple: Often a Type J or K thermocouple is integrated for accurate temperature sensing. Insulation: High-purity magnesium oxide (MgO) is used for electrical insulation and heat conduction. Advantages of Cartridge Heaters With Thermocouples These heaters offer several benefits that make them a popular choice in industries: Precise Temperature Control: Thermocouples enable accurate and real-time temperature monitoring. High Efficiency: They quickly reach desired temperatures, reducing energy consumption. Durability: Built with robust materials to withstand high temperatures and harsh environments. Versatility: Suitable for various applications, from industrial to commercial use. Common Applications of Cartridge Heaters With Thermocouples Cartridge heaters are used in multiple industries. Here’s where they are commonly found: Plastic and Rubber Molding: For heating molds and dies evenly. Packaging Machines: Used in sealing equipment to maintain consistent heat. Medical Devices: Found in diagnostic and sterilization equipment. Food Equipment: Used in cooking, baking, and warming appliances. 3D Printing: Helps in heating nozzles and maintaining stable temperatures. Choosing the Right Cartridge Heater With Thermocouple Selecting the right heater involves several factors. These include size, watt density, and operating temperature. Here’s a quick checklist to help you choose: Size and Fit: Ensure the heater matches the dimensions of the application. Wattage: Higher watt density is needed for faster heating in demanding applications. Temperature Range: Consider the operating environment to choose a suitable material. Type of Thermocouple: Type J and K are the most common for their reliability and range. Maintenance Tips for Cartridge Heaters With Thermocouples Proper care ensures a long service life. Here are some tips: Inspect Regularly: Check for signs of wear or damage. Clean Periodically: Remove dirt or residue to avoid overheating. Ensure Proper Fit: Loose heaters may cause uneven heating or failure. Monitor Thermocouple: Replace if the sensor becomes inaccurate. Final Thoughts Cartridge heaters with thermocouples are reliable and efficient heating tools for precision applications. Their ability to provide controlled heat makes them indispensable in various industries. By understanding how they work and selecting the right model, you can achieve better performance and longer service life. Whether it’s plastic molding or food processing, these heaters are a smart solution for your heating needs.

5 Best Ways to Do Quality 3D Heat Printing

3D printing has changed the way we create and design. To get the best results, you need a reliable setup. One key part is the heater, and that’s why finding the right 3D printer heater manufacturers is so important. A good heater ensures consistent heat, leading to better prints. In this post, we’ll explore five ways to improve your 3D heat printing quality. 1. Choose the Right 3D Printer Heater The heater is the heart of your 3D printer. It controls the temperature, which affects how the material melts and bonds. Picking the right heater ensures smooth and strong prints. Tips for choosing the best heater: Compatibility: Make sure the heater matches your printer model. Power rating: Higher wattage can heat up faster and handle tougher materials. Material: Heaters made with high-grade metals last longer and perform better. Reputation of manufacturers: Research trusted 3D printer heater manufacturers to ensure quality. Heater Type Best For Key Features Ceramic Heaters Consistent heat distribution Durable and stable temperature Cartridge Heaters High heat for advanced materials Compact and efficient design 2. Use High-Quality Filament The filament directly impacts print quality. Cheap materials often lead to uneven melting and weak prints. Checklist for high-quality filament: Consistent diameter for even extrusion. Check for moisture resistance to avoid bubbles. Choose filaments rated for your heater’s temperature range. Popular options include PLA, ABS, and PETG for standard projects, while nylon and carbon-fiber blends work for tougher prints. 3. Calibrate the Printer Properly Calibration ensures that every part of your printer works in harmony. Incorrect settings can ruin your prints. Key calibration steps: Level the print bed: Use a piece of paper to set the gap between the nozzle and the bed. Adjust the nozzle temperature: Follow the filament’s recommended temperature. Check the flow rate: Make sure the material extrudes at the right speed. Test print a calibration model: This will highlight any issues in your settings. Pro tip: Keep a log of your calibration settings for future reference. 4. Control the Print Environment External factors can affect heat distribution and print quality. A stable environment ensures consistent results. Tips to control your workspace: Keep the room free from drafts to avoid uneven cooling. Use an enclosure to maintain a steady temperature. Avoid humid conditions that can affect filament properties. 5. Perform Regular Maintenance Regular maintenance keeps your printer in top condition. A well-maintained machine delivers better prints. Maintenance checklist: Clean the nozzle to prevent clogs. Inspect wires and connectors for wear. Check the heater’s performance regularly to ensure proper function. Lubricate moving parts for smooth operation. Final Thoughts Quality 3D heat printing requires attention to detail and the right equipment. Start by choosing the best 3D printer heater manufacturers to ensure reliability. Pair this with quality filaments, proper calibration, and a stable environment to achieve excellent prints. With regular maintenance, you can ensure long-term success. Stick to these steps, and your prints will turn out smooth, precise, and durable.

How to Find the Best CO2 Heater Element Manufacturer Online

Finding the right CO2 heater element manufacturer is a crucial step for businesses and individuals needing reliable heating solutions. With numerous options available online, the challenge lies in identifying a trusted provider that meets your requirements. CO2 heater elements are widely used in industries like agriculture, medical devices, and manufacturing. Choosing the wrong manufacturer can lead to inefficient systems and increased costs. This guide will help you discover the best online manufacturer while ensuring top-notch quality and service. Why CO2 Heater Elements Are Important CO2 heater elements are vital in maintaining consistent temperatures in equipment that uses carbon dioxide. These heaters enhance performance and ensure energy efficiency. Here’s why they’re critical: Precision Heating: Ensures consistent thermal output for sensitive applications. Energy Efficiency: Reduces energy consumption by delivering targeted heat. Durability: High-quality materials ensure long-lasting performance in demanding environments. Safety: Minimizes risks of overheating or equipment failure. Given their importance, sourcing them from a trusted manufacturer ensures peace of mind and long-term benefits. Steps to Identify a Reliable CO2 Heater Element Manufacturer Online Search for Reputable Companies Begin with a focused online search for manufacturers specializing in CO2 heater elements. Look for high-ranking websites and industry-specific directories. Use search terms like “certified CO2 heater element manufacturers.” Check if the website looks professional and provides detailed product information. Evaluate Product Quality Not all CO2 heater elements are created equal. Look for the following indicators of high-quality products: Material Details: Manufacturers should use corrosion-resistant and heat-tolerant materials like stainless steel. Certifications: Ensure the manufacturer adheres to ISO standards or industry-specific certifications. Customer Reviews: Positive feedback often reflects consistent product quality. Check Manufacturing Capabilities A good manufacturer offers advanced production facilities and flexible customization options. Important factors to assess include: Production Volume: Can they meet your demand scale? Customization: Do they offer size or design modifications for specific applications? Lead Time: How quickly can they deliver your order? Compare Pricing and Warranty Options Price is always a factor, but cheaper doesn’t always mean better. Check for competitive pricing without compromising quality. Request Quotes: Compare prices from multiple manufacturers. Warranty: Choose manufacturers offering solid warranties on their heater elements. Review Customer Support Excellent customer service is an essential marker of a reliable company. Look for manufacturers offering: Technical Assistance: Pre- and post-sale support. Detailed Guides: Product manuals or troubleshooting guides. Responsive Communication: Quick responses to emails or inquiries. Key Features to Look for in a CO2 Heater Element To ensure you’re purchasing the right heater element, consider the following features: Questions to Ask the Manufacturer Asking the right questions helps verify the manufacturer’s credibility and ensures a smoother purchasing experience: What materials are used in your CO2 heater elements? Can you provide a list of certifications or quality standards? Do you offer custom designs for unique applications? What is the typical delivery time for bulk orders? What support do you provide after the purchase? Top Benefits of Choosing the Right Manufacturer When you select a reliable CO2 heater element manufacturer, you enjoy several benefits: Consistent Quality: High-performance products with fewer breakdowns. Reduced Costs: Energy-efficient solutions lower operational expenses. Expert Support: Reliable technical assistance for installation and maintenance. Timely Delivery: Keeps your operations running smoothly. Final Thoughts Finding the best CO2 heater element manufacturer online requires research, attention to detail, and a focus on quality. By following these steps, you can identify a trusted provider offering durable, efficient, and high-performing heater elements. Always prioritize companies with excellent customer reviews, transparent policies, and a commitment to quality standards. A smart choice today ensures long-term benefits for your operations.