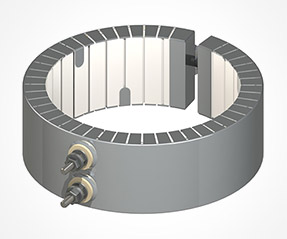

Upgrading your heating system is an important decision that could greatly impact the efficiency and performance of your equipment. With so many options on the market, it can be overwhelming to decide which type of heater to choose. However, if you are looking for a reliable, versatile, and cost-effective solution for your heating needs, band heaters could be the ideal choice.

Here are some of the key benefits of using band heaters:

Versatility

One of the main advantages of band heaters is their versatility. These heaters are available in a wide range of sizes and configurations, making them suitable for various applications. Whether you need to heat a small laboratory instrument or a large industrial machine, you can easily find a band heater to fit your specific needs.

Energy Efficiency

Energy efficiency is a top concern for many businesses, as it directly affects the bottom line. Band heaters are known for their high thermal efficiency, meaning they can transfer heat to the target object more effectively than other types of heaters. This can result in lower energy consumption and cost savings over time.

Durability

Another benefit of band heaters is their durability. Band heaters are designed to withstand harsh industrial environments, high temperatures, and pressure. They can provide reliable heating performance for extended periods with minimal maintenance. The durable construction of these heaters also makes them resistant to vibrations, shocks, and moisture.

Customization

Customization is critical in the industrial world, as every application has its unique needs and challenges. Band heaters can be customized to suit the specific requirements of your equipment or process. You can choose from various materials, watt densities, and other specifications to ensure the best performance and longevity for your heater.

Cost-Effective

Cost is always a consideration when it comes to equipment upgrades. Band heaters are a cost-effective solution compared to other heating options such as infrared heaters or tubular heaters. They are typically less expensive, more durable, and have a longer lifespan than other alternatives.

Easy Installation

Ease of installation is another advantage of band heaters. These heaters can be easily installed and removed without the need for special tools or complicated procedures. Once installed, they require minimal maintenance, resulting in less downtime and cost savings.

Wide Applications

Band heaters have a wide range of applications in various industries, including:

Plastic processing: Band heaters are commonly used in plastic processing equipment such as extruders, injection molding machines, and blow molding machines.

Food and beverage processing: Band heaters can be used in food processing equipment such as ovens, toasters, and fryers.

Chemical processing: Band heaters are used in industrial chemical equipment such as reactors, distillation columns, and heat exchangers.

Semiconductor manufacturing: Band heaters can provide precise and uniform heating for semiconductor manufacturing equipment such as furnaces and wafer processing equipment.

Conclusion

Band heaters are an excellent choice for businesses looking to upgrade their heating system. They offer versatility, energy efficiency, durability, customization, cost effectiveness, easy installation, and are widely applicable across various industries. As a band heater manufacturer, we take pride in producing high-quality heaters that meet our clients’ unique needs and specifications. Whether you need a standard or custom-made band heater, we can help you find the best solution for your equipment or process.