Mica heat proof cable is a game-changer in industries where safety and durability are crucial. These cables are specially designed to withstand extreme conditions, making them ideal for environments with high temperatures, fire risks, and harsh mechanical stress.

If you’ve ever wondered why mica is preferred in these cables and where they are used, this blog will give you all the answers.

What is a Mica Insulated Cable?

Mica is a natural mineral with excellent insulating properties. It can resist extreme heat and does not catch fire easily. Mica insulated cables are built to endure temperatures as high as 1000°C. They consist of mica tape wrapped around conductors to prevent electrical failures. These cables provide high resistance to chemicals, moisture, and abrasion, making them reliable and long-lasting.

Why is Mica Used in Heat Proof Cables?

Mica has unique qualities that make it perfect for use in heat-resistant cables:

- Thermal Stability: Mica can withstand extreme heat without breaking down.

- Dielectric Strength: It acts as an excellent insulator against electrical currents.

- Fire Resistance: Mica is naturally non-flammable, ensuring maximum safety.

- Mechanical Strength: It can resist wear and tear in demanding environments.

Applications of Mica Insulated Cables

Mica insulated cables are essential in industries where extreme conditions exist. Here’s a list of common applications:

1. Fire Protection Systems

- Mica insulated cables are used in fire alarms, emergency lighting, and smoke detection systems.

- They maintain their integrity during fires, ensuring critical systems remain operational.

2. Industrial Heating Equipment

- These cables are ideal for ovens, kilns, and other high-temperature machinery.

- They ensure efficient and safe power transmission even at temperatures exceeding 900°C.

3. Power Plants

- Nuclear and thermal power plants rely on mica heat proof cables to handle high heat and electrical loads.

- They prevent short circuits and equipment failures under extreme conditions.

4. Aerospace and Military Applications

- Aerospace systems and defense equipment demand reliable, heat-resistant cables.

- Mica insulated cables can handle the heat and pressure of advanced machinery.

5. Petrochemical Industry

- Mica insulated cables are used in refineries, gas plants, and chemical facilities.

- They resist chemical corrosion, heat, and mechanical stress.

Advantages of Mica Insulated Cables

Mica heat proof cables come with numerous benefits:

- High Heat Resistance: They function in temperatures beyond most other materials.

- Fire Safety: These cables do not spread flames, ensuring safety in critical scenarios.

- Durability: Resistant to moisture, chemicals, and physical damage, they last longer.

- Electrical Stability: Provide consistent performance under heavy electrical loads.

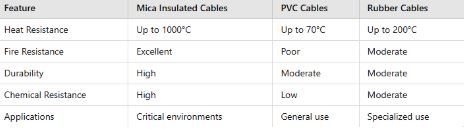

Comparing Mica Insulated Cables to Other Types of Heat Cables

How to Choose the Right Mica Insulated Cable

When selecting mica insulated cables, consider the following factors:

- Temperature Range: Ensure the cable can handle the highest temperature in your application.

- Voltage Requirements: Check the voltage capacity to match your system’s needs.

- Environmental Conditions: Consider factors like humidity, chemicals, and mechanical stress.

- Certifications: Look for compliance with safety standards like IEC or UL.

Maintenance Tips for Mica Insulated Cables

- Inspect cables regularly for signs of wear or damage.

- Keep them away from sharp edges or areas with excessive mechanical stress.

- Use proper connectors to prevent electrical issues.

- Store spare cables in a dry, cool place to maintain their quality.

Final Words

Mica heat proof cable is essential for applications that require exceptional heat resistance and durability. These cables are used in fire protection systems, industrial machinery, power plants, and more. Their reliability and safety features make them a top choice for demanding environments. By choosing the right cable and maintaining it well, you ensure long-term efficiency and protection for your systems.