Description

|

Product Name |

Flange Immersion Heater |

|

Wattage Tolerance |

+5%, -10% |

|

Resistance tolerance |

+10%, -5% |

|

Insulation resistance (cold) |

≥ 500 MΩ |

|

Maximum leakage current (cold) |

≤ 0.5 mA |

|

Tube diameter |

Φ6.5mm-Φ20mm |

|

Insulation Material |

High-purity Mgo |

|

Reisistance wire element |

Ni-Cr or FeCr |

|

Lead Connection Option |

Crimped or Swaged leads |

|

Voltage and power |

customized |

|

Warranty |

one year |

|

Material |

SUS304 SUS321 SUS316 and other customization |

|

Thread Size |

1″,1.25″,1.5″,2″,2.5″ and other customization |

|

Tube Length |

≥200mm |

|

Power |

≥12V |

|

Wattage |

1-12w/cm2 |

|

Shape |

customized according to drawing |

|

Lead and type of connection leads |

10″ Fiberglass Standard(Wire options,silicone high temperature frberglass) |

|

Flange size |

Thread flanges (NPT /BSP:1.5″/2″/2.5″/1.25″ )Round Flange: DN25/DN50/DN100 |

|

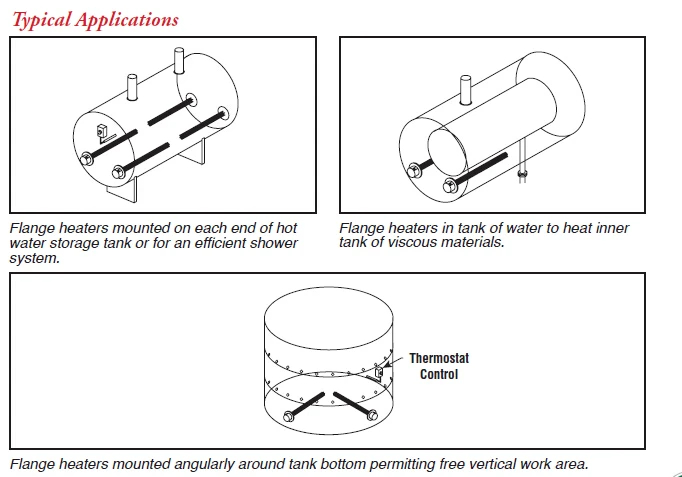

Including flange immersion heater,explosion-proof flange heater, anti-corrosion flange heater, etc |

|

Tubular heating element are used for almost every kind of heating appliances. They are easy to form and feature highest mechanic stability and electric properties at the same time.

Even though Tubular heating element are technically rather mature and universal to use, there exist various new innovative solutions for many applications.

Screw in Tubular heating element are standard for use in liquids like water.

Tubular heating element are easy to install,control and maintain, unique designer as your requirement. For corrosive environment, titanium material or tubular heating elements with additional Teflon cables are available.